PZT-Rohr

PZT-Rohr

Die PZT-Röhre bietet eine starke piezoelektrische Leistung und Langlebigkeit, wodurch sie sich ideal für Ultraschall-, Sensor- und Aktoranwendungen eignet. Die präzise Geometrie und die anpassbaren Optionen ermöglichen es, verschiedene technische Anforderungen zu erfüllen. Wir können hochwertige PZT-Rohre liefern mit verschiedenen Spezifikationen und zu wettbewerbsfähigen Preisen und bieten maßgeschneiderte Lösungen für spezifische Anforderungen.

Oder senden Sie uns eine E-Mail an sales@heegermaterials.com.Datenblatt PZT-Rohr

| Farbe: | Weiß |

| Material: | Blei-Zirkonat-Titanat (PZT) |

| Die Form: | Rohr |

| Dimension: | Standard oder kundenspezifisch |

PZT-Rohr Beschreibung

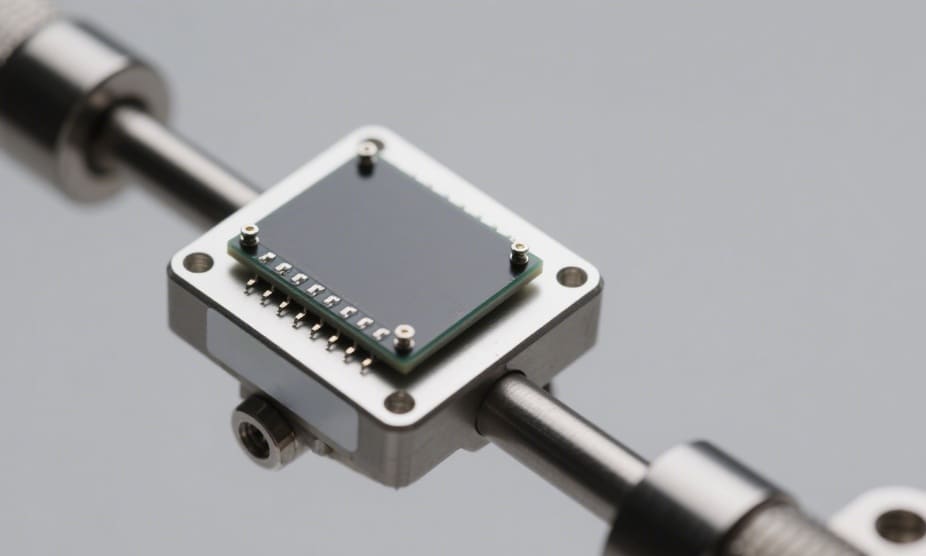

Das PZT-Rohr ist ein zylindrisches Bauteil aus Blei-Zirkonat-Titanat (PZT)-Keramik, das hervorragende piezoelektrische Eigenschaften und eine hohe mechanische Festigkeit aufweist. Es wird häufig in Anwendungen wie Ultraschallwandlern, Sensoren, Aktoren und akustischen Unterwassergeräten eingesetzt, wo eine effiziente Umwandlung von elektrischer und mechanischer Energie erforderlich ist. Mit anpassbaren Abmessungen, Wandstärken und Elektrodenkonfigurationen können PZT-Rohre so konstruiert werden, dass sie spezifische Leistungsanforderungen in Industrie und Forschung erfüllen.

PZT-Rohr Spezifikationen

| Parameter | Spezifikation |

|---|---|

| Äußerer Durchmesser | 5 mm - 140 mm |

| Höhe | 1 mm - 60 mm |

| Innendurchmesser | 1 mm |

| Wanddicke | 1 mm |

| Personalisierung | Verfügbar für Abmessungen und Materialien |

PZT-Rohr Merkmale

- Hohe piezoelektrische Leistung: pzt-Röhre bietet hervorragende piezoelektrische Koeffizienten, die eine effiziente Umwandlung von elektrischer und mechanischer Energie ermöglichen.

- Breiter Frequenzbereich: Sie eignen sich für Anwendungen von niedrigen bis zu hohen Frequenzen und gewährleisten Vielseitigkeit in akustischen und Ultraschallsystemen.

- Dimensionsstabilität: Behält die exakten Abmessungen unter verschiedenen Temperatur- und Lastbedingungen bei und gewährleistet so eine gleichbleibende Leistung.

- Material-Optionen: Erhältlich in verschiedenen PZT-Materialien (PZT-4, PZT-5, PZT-8, etc.), um unterschiedlichen Anwendungsanforderungen gerecht zu werden.

- Anpassbares Design: Abmessungen, Wandstärken und Elektrodenkonfigurationen können für spezifische Projektanforderungen angepasst werden.

PZT-Rohr Anwendungen

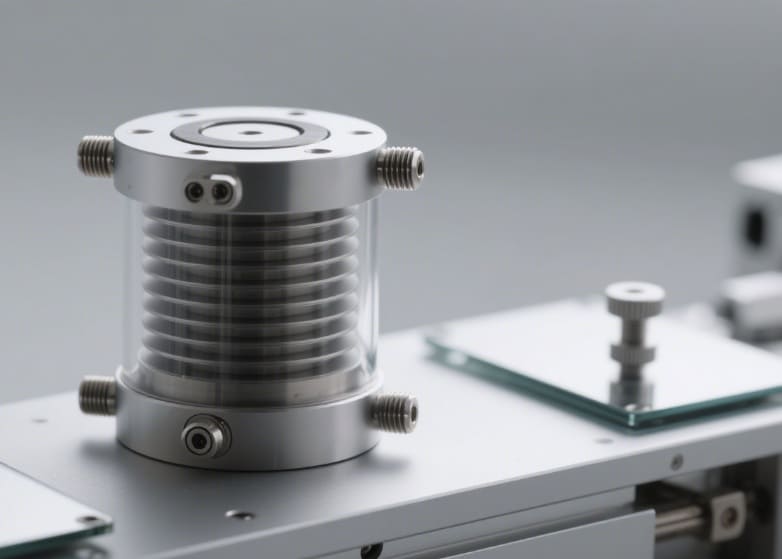

- Ultraschall-Wandler: Wird in Geräten für die Ultraschallreinigung, die medizinische Bildgebung und die zerstörungsfreie Prüfung zur Erzeugung und zum Empfang von Hochfrequenz-Schallwellen verwendet.

- Sonar-Systeme: Dient als Schlüsselkomponente in Unterwasser-Detektions- und Kommunikationssystemen für kommerzielle und militärische Anwendungen.

- Durchflussmessung: Integriert in Ultraschall-Durchflussmesser zur genauen Überwachung von Flüssigkeits- oder Gasströmen in Industrie- und Laborumgebungen.

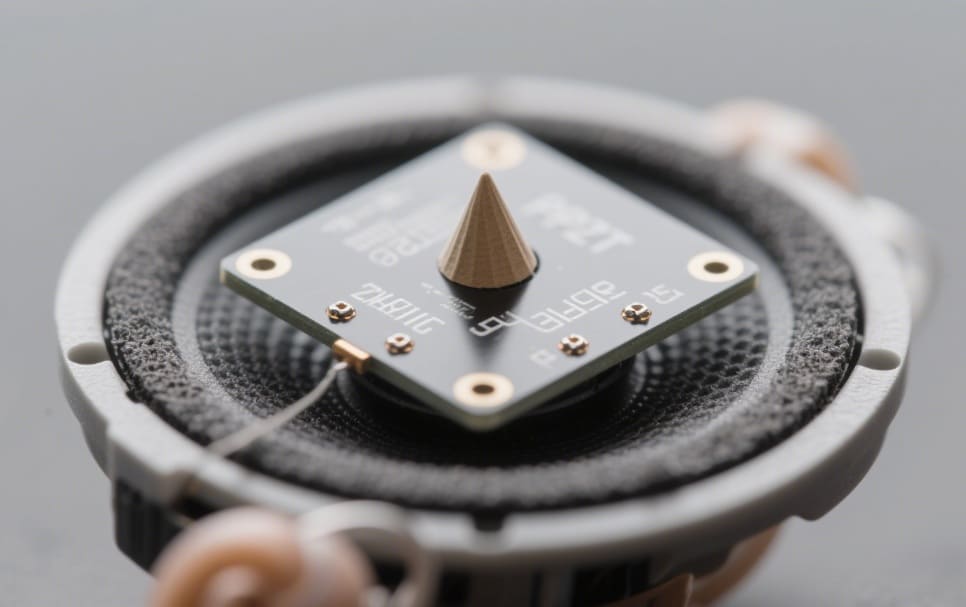

- Aktuatoren und Sensoren: Eingesetzt in Präzisionspositionierungssystemen, Vibrationserkennung und Kraftmessgeräten.

- Akustische Projektoren: Einsatz in akustischen Unterwasserkommunikations- und Tonprojektionssystemen, die hohe Zuverlässigkeit und stabile Leistung erfordern

PZT-Keramik Materialeigenschaften

| Eigenschaften | Materialien | |||||||||||

| PZT4 | PZT5 | PZT8 | ||||||||||

| 840 | 841 | 842** | 844** | 850 | 851** | 854 | 855 | 860 | 880 | 881** | ||

| Relative Dielektrizitätskonstante | KT | 1275 | 1375 | 1375 | 1500 | 1900 | 1950 | 2750 | 3300 | 1200 | 1050 | 1030 |

| Dielektrischer Verlustfaktor (%) | tan δ | 0.60 | 0.40 | 0.45 | 0.40 | ≤ 2.00 | 1.50 | ≤ 2.00 | ≤ 2.50 | ≤2.00 | 0.40 | 0.40 |

| Curie-Temperatur (°C) | Tc | 325 | 320 | 325 | 320 | 360 | 360 | 250 | 200 | 360 | 310 | 310 |

| Elektromechanischer Kopplungskoeffizient | kp | 0.59 | 0.60 | 0.65 | 0.68 | 0.63 | 0.71 | 0.66 | 0.68 | 0.50 | 0.50 | 0.58 |

| k33 | 0.72 | 0.68 | – | – | 0.72 | – | 0.68 | 0.76 | 0.45 | 0.62 | – | |

| k31 | 0.35 | 0.33 | – | – | 0.36 | – | – | 0.40 | – | 0.30 | – | |

| k15 | 0.70 | 0.67 | – | – | 0.68 | – | – | 0.66 | – | 0.55 | – | |

| kt | – | – | 0.48 | 0.48 | – | 0.51 | – | – | – | – | 0.46 | |

| Piezoelektrische Ladungskonstante (10-¹² C/N oder 10-¹² m/V) | d33 | 290 | 300 | 300 | 300 | 400 | 400 | 600 | 630 | 380 | 215 | 220 |

| -d31 | 125 | 109 | – | – | 175 | – | 260 | 276 | – | 95 | – | |

| d15 | 480 | 450 | – | – | 590 | – | 625 | 720 | – | 330 | – | |

| Piezoelektrische Spannungskonstante (10-³ Vm/N oder 10-³ m²/C) | g33 | 26.5 | 25.5 | 26.3 | 24.5 | 24.8 | 24.8 | 25.5 | 21.0 | 38.0 | 25.0 | 26.7 |

| -g31 | 11.0 | 10.5 | – | – | 12.4 | – | – | 9.0 | – | 10.0 | – | |

| g15 | 38.0 | 35.0 | – | – | 36.0 | – | – | 27.0 | – | 28.0 | – | |

| Elastizitätsmodul (10¹⁰ N/m²) | YE11 | 8.0 | 7.6 | 8.0 | 7.6 | 6.3 | 6.3 | 6.0 | 5.9 | – | 9.0 | 9.0 |

| YE33 | 6.8 | 6.3 | 6.8 | 6.3 | 5.4 | 5.4 | 5.2 | 5.1 | – | 7.2 | 7.2 | |

| Frequenzkonstante (Hz-m oder m/s) | NL (Länge Richtung) | 1524 | 1700 | – | – | 1500 | – | – | 1390 | – | 1725 | – |

| NT (Richtung der Dicke) | 2005 | 2005 | 2050 | 2050 | 2040 | 2040 | 2000 | 2079 | 1390 | 2110 | 2050 | |

| NP (Ebenerdige Richtung) | 2130 | 2055 | 2230 | 2250 | 1980 | 2080 | 1972 | 1920 | 1900 | 2120 | 2300 | |

| Dichte (g/cm³) | ρ | 7.6 | 7.6 | 7.6 | 7.7 | 7.6 | 7.6 | 7.6 | 7.6 | 6.6 | 7.6 | 7.6 |

| Mechanischer Qualitätsfaktor | Qm | 500 | 1400 | 600 | 1500 | 80 | 80 | 70 | 65 | 50 | 1000 | 1000 |

| Akustische Impedanz (Mrayl) | – | – | – | – | 31.5 | – | – | – | 16.5 | – | – | |

Anmerkungen:

- @ 1 kHz, niedriges elektrisches Feld

- Bei den Materialien 842, 844, 851 und 881 handelt es sich um Lagerprodukte, die nur als Referenz dienen und nicht für kundenspezifische Anpassungen verfügbar sind.

PZT-Keramik Toleranzen

PZT Materialeigenschaft Parametertoleranzen:

| Parameter | Standard-Toleranz | Strengere Toleranzen optional erhältlich |

|---|---|---|

| Kapazität | ±20% | Ja |

| d33 (Piezo-Koeffizient) | ±20% | Ja |

| Frequenz | ±5% | ±0,5% |

Maßtoleranzen:

| Form & Dimension | Standard Wertebereich | Toleranz (±) |

| Scheibe / Ring / Rohr | ||

| Äußerer Durchmesser | < 25 mm | 0,25 mm |

| ≥ 25 mm bis < 38 mm | 0,38 mm | |

| ≥ 38 mm bis < 50 mm | 0,60 mm | |

| ≥ 50 mm | 1,00 mm | |

| Ring/Rohr | ||

| Innendurchmesser | < 6 mm | 0,25 mm |

| ≥ 6 mm bis < 13 mm | 0,38 mm | |

| ≥ 13 mm bis < 25 mm | 0,50 mm | |

| ≥ 25 mm | 0,60 mm | |

| Quadratische Platte | ||

| Länge oder Breite | < 13 mm | 0,13 mm |

| ≥ 13 mm bis < 25 mm | 0,25 mm | |

| ≥ 25 mm bis 38 mm | 0,38 mm | |

| ≥ 38 mm bis < 50 mm | 0,60 mm | |

| ≥ 50 mm | 1,00 mm | |

| Dicke | 0,20 mm bis < 5,00 mm | 0,025 mm |

| ≥ 5,00 mm | 0,05 mm | |

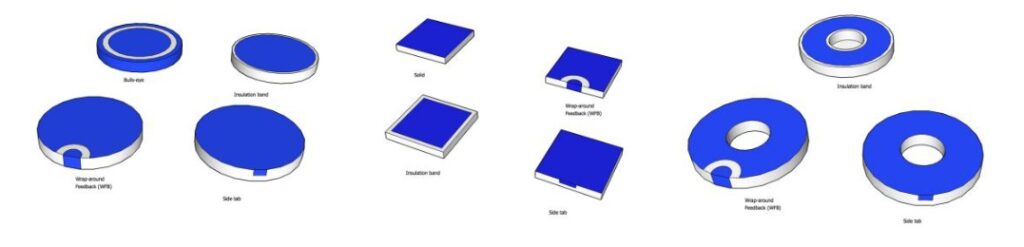

PZT-Elektrode Spezifikationen

- Standard-Elektrodenmaterial: Silber

- Optionale Elektrodenmaterialien: Gold, Nickel

- Standard-Elektrodenkonfiguration: Feste Elektroden, die die gesamte obere und untere Fläche bedecken

- Röhrenförmige Elektrodenkonfiguration: Elektroden an Innen- und Außenwand (Innenwand: positive Elektrode; Außenwand: negative Elektrode)

- Kundenspezifische Elektrodenausführungen auf Anfrage erhältlich

| Material | AC-Antriebsspannung (V/mm) | DC-Antriebsspannung (V/mm) | Anpassbare maximale Spannung (V/mm) |

| PZT4 | 360 ~ 440 | 720 ~ 880 | Bis zu 1000 |

| PZT5 | 200 ~ 280 | 400 ~ 560 | |

| PZT8 | 360 ~ 440 | 720 ~ 880 |

PZT-Keramik-Verpackungen

PZT-Keramikprodukte werden in der Regel in vakuumversiegelten Beuteln verpackt, um Feuchtigkeit oder Verunreinigungen zu vermeiden, und mit Schaumstoff umwickelt, um Erschütterungen und Stöße während des Transports zu dämpfen und die Qualität der Produkte im Originalzustand zu gewährleisten.

Herunterladen

Angebot einholen

Wir werden das prüfen und uns innerhalb von 24 Stunden bei Ihnen melden.