PZT Platte/Blech/Scheibe

PZT Platte/Blech/Scheibe

PZT Platte/Blech/Scheibe bietet eine herausragende piezoelektrische Leistung mit hoher Empfindlichkeit, starker elektromechanischer Kopplung und zuverlässiger Stabilität und eignet sich daher gut für Anwendungen in Sensoren, Aktoren, Ultraschallwandlern und Präzisionspositioniersystemen. Mit ihrem hervorragenden Frequenzgang und ihrer Langlebigkeit gewährleisten sie eine gleichbleibende Leistung in anspruchsvollen Industrie- und Forschungsumgebungen. Wir können hochwertige PZT-Platten/Bleche/Scheiben liefern. mit verschiedenen Spezifikationen und zu wettbewerbsfähigen Preisen und bieten maßgeschneiderte Lösungen für spezifische Anforderungen.

Oder senden Sie uns eine E-Mail an sales@heegermaterials.com.PZT Platte/Blatt/Scheibe Datenblatt

| Farbe: | Weiß |

| Material: | Blei-Zirkonat-Titanat (PZT) |

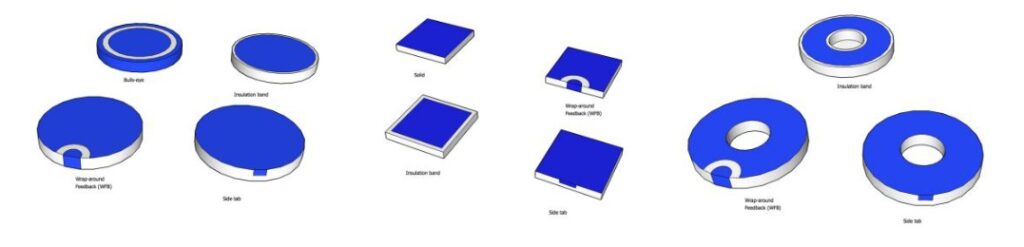

| Die Form: | Platte / Blech / Scheibe |

| Dimension: | Standard oder kundenspezifisch |

PZT Platte/Blatt/Scheibe Beschreibung

PZT-Platten/Bleche/Scheiben sind ein hochleistungsfähiges piezoelektrisches Keramikprodukt, das für seine starke elektromechanische Kopplung, seine hohe Dielektrizitätskonstante und sein stabiles Frequenzverhalten bekannt ist. Es wird häufig in Sensoren, Aktuatoren, Ultraschallgeräten und Präzisionsbewegungssystemen eingesetzt, bei denen eine schnelle Reaktion und Zuverlässigkeit entscheidend sind. Mit seiner ausgezeichneten mechanischen Festigkeit und gleichbleibenden Leistung über eine Reihe von Betriebsbedingungen hinweg gewährleistet es eine lange Lebensdauer und präzise Funktionalität in anspruchsvollen Industrie- und Forschungsumgebungen.

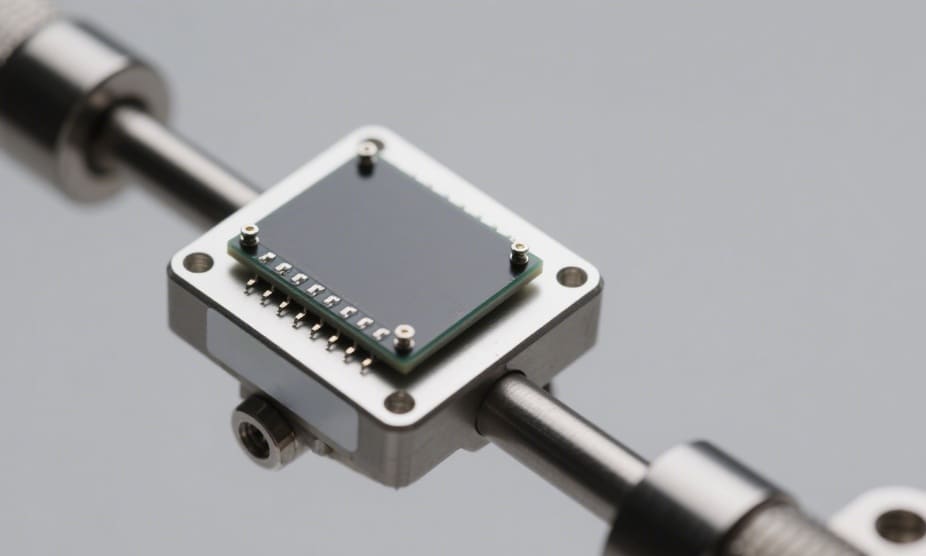

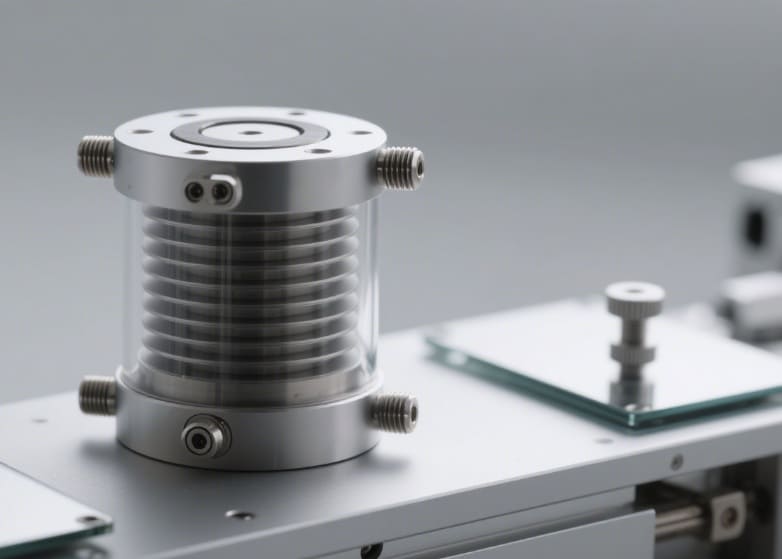

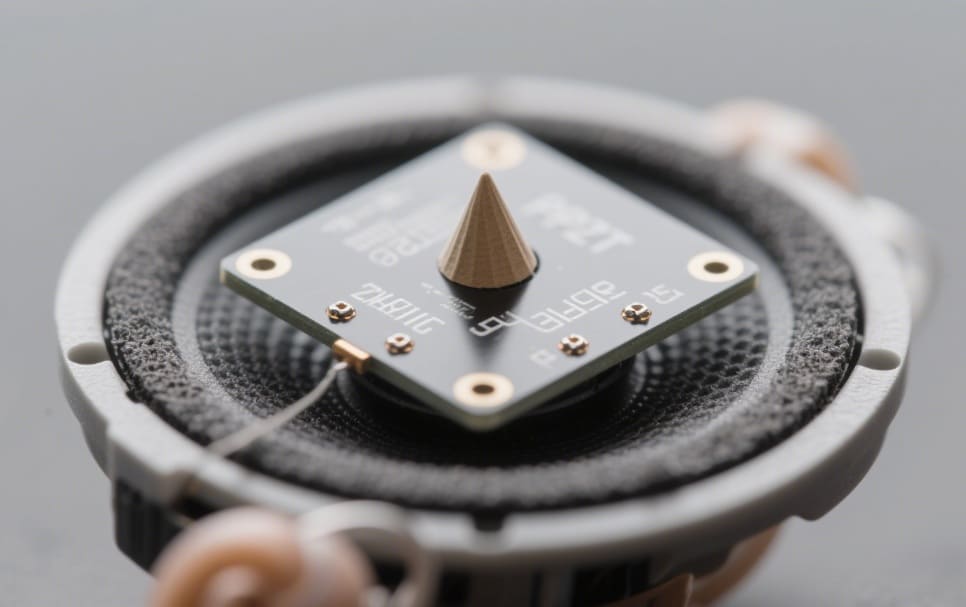

PZT-Platte PZT-Platte PZT-Scheibe

Quadratische PZT-Platte Technische Daten

| Modell | Länge L [mm] ±0,1 | Breite W [mm] ±0,1 | Höhe [mm] ±0,05 | Gewicht [g] ±5% | Steuerspannung [V] | Verdrängung [μm] ±15% | Kapazität [nF] ±15% | Resonanzfrequenz [kHz] ±20% | Steifigkeit [N/μm] ±20% | Kraft [N] ±20% |

|---|---|---|---|---|---|---|---|---|---|---|

| NAC2001 | 2 | 2 | 2 | 0.07 | 60 | 3 | 150 | >486 | 56 | 168 |

| NAC2002 | 3 | 3 | 2 | 0.15 | 60 | 3 | 400 | >486 | 126 | 378 |

| NAC2003 | 5 | 5 | 2 | 0.37 | 60 | 3 | 1080 | >486 | 350 | 1050 |

| NAC2011 | 2 | 2 | 2 | 0.05 | 150 | 3.3 | 25 | >486 | 51 | 168 |

| NAC2012 | 3 | 3 | 2 | 0.14 | 150 | 3.3 | 65 | >486 | 115 | 378 |

| NAC2013 | 5 | 5 | 2 | 0.40 | 150 | 3.3 | 190 | >486 | 318 | 1050 |

| NAC2014 [1] | 7 | 7 | 2 | 0.79 | 150 | 3.3 | 380 | >486 | 624 | 2060 |

| NAC2015 [2] | 10 | 10 | 2 | 1.58 | 150 | 3.3 | 760 | >486 | 1273 | 4200 |

| NAC2021 [1] | 7 | 7 | 2 | 0.78 | 200 | 3.3 | 220 | >486 | 624 | 2060 |

| NAC2022 [2] | 10 | 10 | 2 | 1.61 | 200 | 3.3 | 440 | >486 | 1273 | 4200 |

| NAC2023 [3] | 15 | 15 | 2 | 3.66 | 200 | 3.3 | 970 | >486 | 2864 | 9450 |

| NAC2017 | 20 | 20 | 2 | 6.40 | 200 | 3.3 | 1800 | >486 | 5091 | 16800 |

| NAC2024 | 3 | 3 | 2 | 0.14 | 200 | 1.9 | 25 | >500 | 161 | 290 |

| NAC2025 | 5 | 5 | 2 | 0.38 | 200 | 1.9 | 80 | >500 | 400 | 800 |

| 012605 Goldelektrode | 3 | 3 | 1 | 0.09 | 200 | 1.5 | 25 | – | 210 | 360 |

Anmerkungen:

- Bei kleinen Amplituden (ein paar Volt) kann die Betriebsfrequenz einige zehn kHz erreichen.

- Maximale Betriebstemperatur: 200°C. Verwenden Sie Hochtemperatur-Lötverfahren.

- [1] Längen- und Breitentoleranz ±0,15 mm

- [2] Längen- und Breitentoleranz ±0,2 mm

- [3] Längen- und Breitentoleranz ±0,3 mm

PZT Platte/Blatt/Scheibe Merkmale

- Hohe piezoelektrische Leistung: Bietet eine starke elektromechanische Kopplung und ist damit ideal für Sensoren, Aktuatoren und Ultraschallwandler.

- Anpassbar Abmessungen: Erhältlich in verschiedenen Größen, Formen und Dicken, um den unterschiedlichen Anforderungen von Industrie und Forschung gerecht zu werden.

- Stabile Materialeigenschaften: Gleichbleibende dielektrische, mechanische und thermische Leistung über einen großen Temperaturbereich.

- Breite Frequenzanpassungsfähigkeit: Unterstützt sowohl den Betrieb in Nieder- als auch in Hochfrequenzanwendungen und gewährleistet so Designflexibilität.

- Langlebig und verlässlich: Bietet eine lange Lebensdauer und ist resistent gegen mechanische Abnutzung und Umwelteinflüsse.

PZT Platte/Blech/Scheibe Anwendungen

- Ultraschall-Wandler: Wird in der medizinischen Bildgebung, bei der Fehlererkennung und in Unterwassersonarsystemen eingesetzt.

- Präzisionssensoren: Wird in Druck-, Beschleunigungs- und Vibrationsmessgeräten eingesetzt.

- Stellantriebe: Integriert in Präzisionspositionierungssysteme, Mikropumpen und adaptive Optiken.

- Energiegewinnungsgeräte: Wandelt mechanische Schwingungen in elektrische Energie für Elektronik mit geringem Stromverbrauch um.

- Akustische Geräte: Wird in Lautsprechern, Buzzern und Geräten zur Erzeugung von Schallwellen verwendet.

PZT-Keramik Materialeigenschaften

| Eigenschaften | Materialien | |||||||||||

| PZT4 | PZT5 | PZT8 | ||||||||||

| 840 | 841 | 842** | 844** | 850 | 851** | 854 | 855 | 860 | 880 | 881** | ||

| Relative Dielektrizitätskonstante | KT | 1275 | 1375 | 1375 | 1500 | 1900 | 1950 | 2750 | 3300 | 1200 | 1050 | 1030 |

| Dielektrischer Verlustfaktor (%) | tan δ | 0.60 | 0.40 | 0.45 | 0.40 | ≤ 2.00 | 1.50 | ≤ 2.00 | ≤ 2.50 | ≤2.00 | 0.40 | 0.40 |

| Curie-Temperatur (°C) | Tc | 325 | 320 | 325 | 320 | 360 | 360 | 250 | 200 | 360 | 310 | 310 |

| Elektromechanischer Kopplungskoeffizient | kp | 0.59 | 0.60 | 0.65 | 0.68 | 0.63 | 0.71 | 0.66 | 0.68 | 0.50 | 0.50 | 0.58 |

| k33 | 0.72 | 0.68 | – | – | 0.72 | – | 0.68 | 0.76 | 0.45 | 0.62 | – | |

| k31 | 0.35 | 0.33 | – | – | 0.36 | – | – | 0.40 | – | 0.30 | – | |

| k15 | 0.70 | 0.67 | – | – | 0.68 | – | – | 0.66 | – | 0.55 | – | |

| kt | – | – | 0.48 | 0.48 | – | 0.51 | – | – | – | – | 0.46 | |

| Piezoelektrische Ladungskonstante (10-¹² C/N oder 10-¹² m/V) | d33 | 290 | 300 | 300 | 300 | 400 | 400 | 600 | 630 | 380 | 215 | 220 |

| -d31 | 125 | 109 | – | – | 175 | – | 260 | 276 | – | 95 | – | |

| d15 | 480 | 450 | – | – | 590 | – | 625 | 720 | – | 330 | – | |

| Piezoelektrische Spannungskonstante (10-³ Vm/N oder 10-³ m²/C) | g33 | 26.5 | 25.5 | 26.3 | 24.5 | 24.8 | 24.8 | 25.5 | 21.0 | 38.0 | 25.0 | 26.7 |

| -g31 | 11.0 | 10.5 | – | – | 12.4 | – | – | 9.0 | – | 10.0 | – | |

| g15 | 38.0 | 35.0 | – | – | 36.0 | – | – | 27.0 | – | 28.0 | – | |

| Elastizitätsmodul (10¹⁰ N/m²) | YE11 | 8.0 | 7.6 | 8.0 | 7.6 | 6.3 | 6.3 | 6.0 | 5.9 | – | 9.0 | 9.0 |

| YE33 | 6.8 | 6.3 | 6.8 | 6.3 | 5.4 | 5.4 | 5.2 | 5.1 | – | 7.2 | 7.2 | |

| Frequenzkonstante (Hz-m oder m/s) | NL (Länge Richtung) | 1524 | 1700 | – | – | 1500 | – | – | 1390 | – | 1725 | – |

| NT (Richtung der Dicke) | 2005 | 2005 | 2050 | 2050 | 2040 | 2040 | 2000 | 2079 | 1390 | 2110 | 2050 | |

| NP (Ebenerdige Richtung) | 2130 | 2055 | 2230 | 2250 | 1980 | 2080 | 1972 | 1920 | 1900 | 2120 | 2300 | |

| Dichte (g/cm³) | ρ | 7.6 | 7.6 | 7.6 | 7.7 | 7.6 | 7.6 | 7.6 | 7.6 | 6.6 | 7.6 | 7.6 |

| Mechanischer Qualitätsfaktor | Qm | 500 | 1400 | 600 | 1500 | 80 | 80 | 70 | 65 | 50 | 1000 | 1000 |

| Akustische Impedanz (Mrayl) | – | – | – | – | 31.5 | – | – | – | 16.5 | – | – | |

Anmerkungen:

- @ 1 kHz, niedriges elektrisches Feld

- Bei den Materialien 842, 844, 851 und 881 handelt es sich um Lagerprodukte, die nur als Referenz dienen und nicht für kundenspezifische Anpassungen verfügbar sind.

PZT-Keramik Toleranzen

PZT Materialeigenschaft Parametertoleranzen:

| Parameter | Standard-Toleranz | Strengere Toleranzen optional erhältlich |

|---|---|---|

| Kapazität | ±20% | Ja |

| d33 (Piezo-Koeffizient) | ±20% | Ja |

| Frequenz | ±5% | ±0,5% |

Maßtoleranzen:

| Form & Dimension | Standard Wertebereich | Toleranz (±) |

| Scheibe / Ring / Rohr | ||

| Äußerer Durchmesser | < 25 mm | 0,25 mm |

| ≥ 25 mm bis < 38 mm | 0,38 mm | |

| ≥ 38 mm bis < 50 mm | 0,60 mm | |

| ≥ 50 mm | 1,00 mm | |

| Ring/Rohr | ||

| Innendurchmesser | < 6 mm | 0,25 mm |

| ≥ 6 mm bis < 13 mm | 0,38 mm | |

| ≥ 13 mm bis < 25 mm | 0,50 mm | |

| ≥ 25 mm | 0,60 mm | |

| Quadratische Platte | ||

| Länge oder Breite | < 13 mm | 0,13 mm |

| ≥ 13 mm bis < 25 mm | 0,25 mm | |

| ≥ 25 mm bis 38 mm | 0,38 mm | |

| ≥ 38 mm bis < 50 mm | 0,60 mm | |

| ≥ 50 mm | 1,00 mm | |

| Dicke | 0,20 mm bis < 5,00 mm | 0,025 mm |

| ≥ 5,00 mm | 0,05 mm | |

PZT-Elektrode Spezifikationen

- Standard-Elektrodenmaterial: Silber

- Optionale Elektrodenmaterialien: Gold, Nickel

- Standard-Elektrodenkonfiguration: Feste Elektroden, die die gesamte obere und untere Fläche bedecken

- Röhrenförmige Elektrodenkonfiguration: Elektroden an Innen- und Außenwand (Innenwand: positive Elektrode; Außenwand: negative Elektrode)

- Kundenspezifische Elektrodenausführungen auf Anfrage erhältlich

| Material | AC-Antriebsspannung (V/mm) | DC-Antriebsspannung (V/mm) | Anpassbare maximale Spannung (V/mm) |

| PZT4 | 360 ~ 440 | 720 ~ 880 | Bis zu 1000 |

| PZT5 | 200 ~ 280 | 400 ~ 560 | |

| PZT8 | 360 ~ 440 | 720 ~ 880 |

PZT-Keramik-Verpackungen

PZT-Keramikprodukte werden in der Regel in vakuumversiegelten Beuteln verpackt, um Feuchtigkeit oder Verunreinigungen zu vermeiden, und mit Schaumstoff umwickelt, um Erschütterungen und Stöße während des Transports zu dämpfen und die Qualität der Produkte im Originalzustand zu gewährleisten.

Herunterladen

Angebot einholen

Wir werden das prüfen und uns innerhalb von 24 Stunden bei Ihnen melden.