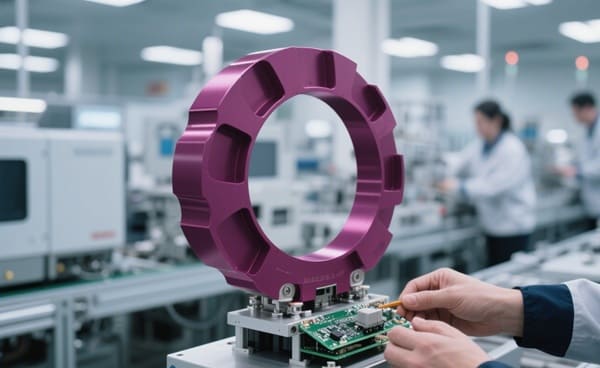

Anillo de hexaboruro de lantano

Anillo de hexaboruro de lantano

El anillo de hexaboruro de lantano ofrece una excelente estabilidad térmica, alta conductividad eléctrica y excelentes características de emisión de electrones. Con una baja tasa de evaporación y una gran resistencia a la corrosión química, este anillo es ideal para su uso en entornos de alto vacío, como sistemas de haces de electrones, fuentes de plasma y aplicaciones de emisión termoiónica. Su estructura anular garantiza una distribución uniforme de la corriente y un rendimiento duradero en condiciones de funcionamiento extremas. Podemos suministrar anillos de hexaboruro de lantano de alta calidad con diversas especificaciones y precios competitivos, ofreciendo soluciones personalizadas para satisfacer requisitos específicos.

O envíenos un correo electrónico a sales@heegermaterials.com.Ficha técnica del anillo de hexaboruro de lantano

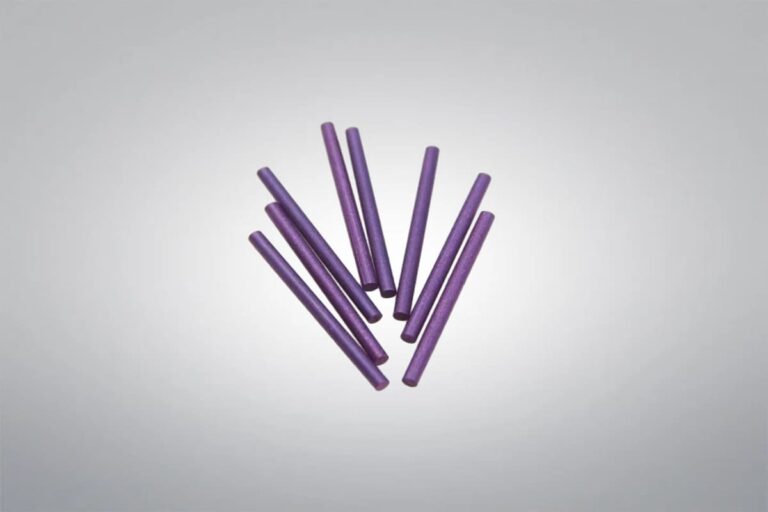

| Color: | Morado |

| Fórmula química: | LaB6 |

| Gama de diámetros: | personalizado |

| Rango de grosor: | personalizado |

Anillo de hexaboruro de lantano Descripción

El anillo de hexaboruro de lantano es una pieza cerámica de gran pureza reconocida por su emisión termoiónica superior y su larga vida útil en entornos extremos. Diseñado para su uso en física de altas energías, instrumentos de análisis de superficies y electrónica de vacío, este material garantiza una emisión de electrones y una resistencia térmica fiables. Su excelente función de trabajo y eficacia de emisión lo convierten en la opción preferida en sistemas que requieren haces de electrones estables, especialmente en funcionamiento continuo a altas temperaturas.

Composiciones químicas del anillo de hexaboruro de lantano

| Pureza de LaB6: 99%, 99,9%, 99,9995%, B(% mín.): 31% | |||

| Impurezas de tierras raras | Impurezas no RE | ||

| Ce | <120ppm | Fe | <250ppm |

| Pr | <150ppm | Si | <100ppm |

| Nd | <180ppm | Ca | <90ppm |

| Sm | <112ppm | C | <300ppm |

| Y | <250ppm | Mg | <100ppm |

| Ti | <100ppm | ||

Características del anillo de hexaboruro de lantano

- Extraordinario rendimiento de la emisión termoiónica: El anillo de hexaboruro de lantano ofrece una baja función de trabajo y una alta densidad de corriente de emisión, lo que lo hace ideal para aplicaciones de cátodos termoiónicos en dispositivos electrónicos de vacío.

- Excepcional resistencia a altas temperaturas: Con puntos de fusión superiores a 2500 °C, el anillo de hexaboruro de lantano permanece estable y fiable bajo cargas térmicas extremas, ideal para operaciones de larga duración.

- Baja tasa de evaporación: Gracias a su densa estructura cristalina, el anillo de hexaboruro de lantano presenta una pérdida mínima de material, lo que garantiza su longevidad incluso en entornos de altas temperaturas continuas.

- Excelente conductividad eléctrica: Su alta conductividad permite un flujo de corriente eficiente, lo que es crucial para un funcionamiento estable en fuentes de iones, sistemas de haces de electrones y otros dispositivos de alta potencia.

- Resistencia a la corrosión y a la oxidación: El anillo de hexaboruro de lantano resiste la degradación en entornos reactivos o de vacío, manteniendo su integridad física y química a lo largo del tiempo.

Aplicaciones del anillo de hexaboruro de lantano

- Sistemas de generación de plasma: El anillo de hexaboruro de lantano se utiliza ampliamente en generadores de plasma en los que la emisión estable y eficiente de electrones es esencial para la formación de plasma de alta densidad.

- Fuentes de iones de RF y CC: Sirve como material catódico robusto en fuentes de iones de radiofrecuencia y corriente continua para su uso en la fabricación de semiconductores, la modificación de superficies y la investigación.

- Espectrómetros de masas: El anillo de hexaboruro de lantano garantiza una emisión de electrones fiable en los instrumentos de espectrometría de masas, mejorando la eficacia de la ionización y la precisión de las mediciones.

- Dispositivos de haz de electrones: Se utiliza en microscopios electrónicos de barrido (SEM), soldadores por haz de electrones y sistemas litográficos debido a su salida de electrones constante y su larga vida útil.

- Conversión de energía termoiónica: Desempeña un papel en la conversión de calor en electricidad mediante emisión termoiónica, especialmente en sistemas energéticos experimentales que funcionan a altas temperaturas.

Propiedades cerámicas del hexaboruro de lantano

Mecanizado de material cerámico de hexaboruro de lantano

La cerámica de hexaboruro de lantano (LaB6) es un material especializado apreciado por su excelente emisión termoiónica, alto punto de fusión y estabilidad química. Estas propiedades lo hacen esencial en las aplicaciones de emisión de electrones, pero también plantean problemas de mecanizado debido a su dureza y fragilidad. Entre las consideraciones clave para el mecanizado se incluyen:

- Cortando: Se necesitan herramientas de precisión diamantadas o métodos de corte por láser para conseguir bordes limpios y evitar microfisuras y daños en la superficie.

- Rectificado: Las muelas de diamante finas proporcionan la precisión necesaria para mantener las tolerancias dimensionales y la suavidad de la superficie, especialmente en el caso de componentes intrincados o pequeños.

- Perforación: Las técnicas de mecanizado por ultrasonidos o chorro de agua abrasivo se utilizan a menudo para crear orificios y características precisas sin inducir tensiones térmicas ni grietas.

- Acabado superficial: Los procesos de pulido mejoran la calidad de la superficie, reducen la dispersión de electrones y aumentan la eficacia de emisión, lo que es fundamental para las aplicaciones de cátodos de alto rendimiento.

Envases cerámicos de hexaboruro de lantano

Los productos cerámicos de hexaboruro de lantano suelen envasarse en bolsas selladas al vacío para evitar la humedad o la contaminación y se envuelven con espuma para amortiguar las vibraciones y los impactos durante el transporte, lo que garantiza la calidad de los productos en su estado original.

Descargar

Solicitar presupuesto

Lo comprobaremos y le responderemos en 24 horas.