Zirkoniumdioxid-Keramik-Kugel

Zirkoniumdioxid-Keramik-Kugel

Reinheit: ≥99%

Durchmesser: φ0,1~φ50 mm, oder kundenspezifisch

Zirkoniumdioxid-Keramik-KugelDie aus hochreinem Zirkoniumoxid hergestellten Kugeln sind für ihre beeindruckende Härte, Verschleißfestigkeit und thermische Stabilität bekannt. Sie ist haltbarer und leichter als herkömmliche Stahlkugeln und damit ideal für Hochgeschwindigkeits-, Hochtemperatur- und anspruchsvolle Anwendungen wie Luft- und Raumfahrt und medizinische Geräte. Diese Zirkoniumdioxid-Keramikkugeln verringern die Reibung, verhindern Lichtbögen und minimieren den Verschleiß, was zu langlebigeren Lagern mit verbesserter Leistung in verschiedenen rauen Umgebungen führt. Wir können hochwertige Zirkoniumdioxid-Keramikkugeln mit verschiedenen Spezifikationen und zu wettbewerbsfähigen Preisen liefern und bieten maßgeschneiderte Lösungen für spezifische Anforderungen.

Oder senden Sie uns eine E-Mail an sales@heegermaterials.com.Datenblatt Zirkoniumdioxid-Keramikkugeln

| Referenz-Code: | HM2603 |

| Reinheit: | ≥99% |

| Farbe: | Weiß |

| Chemische Formel: | ZrO2 |

| Werkstoffklassen: | Ultraharte Qualität, Ultraharte HIP-Qualität, 3YZ-Keramik-Qualität, Nano-HIP-Qualität |

| Maximale Betriebstemperatur: | 900°C |

| Durchmesser: | φ0,1~φ50 mm, oder kundenspezifisch |

| Präzisionsklasse: | G10, G20, G40, G60...... |

| Material: | ZrO2: 94,8±0,5%, Y2O3: 5,2±0,5%, oder kundenspezifisch |

Zirkoniumdioxid-Keramikkugel Beschreibung

Zirkoniumdioxid-Keramikkugeln sind hochentwickelte keramische Komponenten, die für ihre außergewöhnliche Härte, Verschleißfestigkeit und Korrosionsbeständigkeit bekannt sind. Diese Kugeln sind nicht magnetisch und nicht leitend, wodurch sie sich für den Einsatz in Umgebungen eignen, in denen Metalle versagen könnten, z. B. unter korrosiven oder Hochtemperaturbedingungen. Dank ihrer hervorragenden mechanischen Eigenschaften werden Zirkoniumdioxid-Keramikkugeln häufig in Hochgeschwindigkeitsanwendungen wie der Luft- und Raumfahrt und der Automobilindustrie sowie in medizinischen Präzisionsgeräten, zahnmedizinischen Werkzeugen und hochpräzisen Messinstrumenten eingesetzt. Aufgrund ihrer Langlebigkeit und ihrer Fähigkeit, ihre Leistung auch unter extremen Bedingungen aufrechtzuerhalten, sind sie die ideale Wahl für ein breites Spektrum anspruchsvoller Anwendungen.

Zirkoniumdioxid-Keramikkugel Merkmale

- Hohe Festigkeit: Zirkoniumdioxid-Keramikkugeln haben eine hervorragende mechanische Festigkeit, die es ihnen ermöglicht, hohen Lasten und Belastungen standzuhalten, ohne ihre strukturelle Integrität zu beeinträchtigen.

- Abnutzungswiderstand: Diese Kugeln weisen eine hervorragende Verschleißfestigkeit auf, was den Bedarf an häufiger Wartung und Austausch verringert und somit die Betriebskosten senkt.

- Korrosionsbeständigkeit: Zirkoniumdioxid-Keramikkugeln sind äußerst korrosionsbeständig und daher ideal für den Einsatz in rauen chemischen Umgebungen.

- Niedriger Reibungskoeffizient: Mit ihrem niedrigen Reibungskoeffizienten tragen sie dazu bei, den Energieverbrauch und die Wärmeentwicklung zu minimieren und die Effizienz der Maschinen zu verbessern.

- Hohe Härte: Die extrem harten Zirkoniumdioxid-Keramikkugeln behalten ihre Form und Integrität auch unter hoher Belastung bei und gewährleisten so eine lang anhaltende Leistung.

- Hochtemperaturbeständigkeit: Diese Kugeln können hohen Temperaturen standhalten, ohne sich zu zersetzen, und sind daher ideal für Hochtemperaturanwendungen.

- Nichtmagnetisch: Zirkoniumdioxid-Keramikkugeln sind nicht magnetisch und eignen sich daher ideal für Anwendungen, bei denen magnetische Störungen ein Problem darstellen könnten.

Zirkoniumdioxid-Keramikkugeln Anwendungen

- Hochdruck-Ausrüstung: Zirkoniumdioxid-Keramikkugeln werden häufig in Ventilkugeln und -sitzen für Hochdruckgeräte verwendet und bieten eine lange Lebensdauer und Widerstandsfähigkeit gegen mechanische Stöße und Verschleiß.

- Feinmechanische Bearbeitung: Diese Keramikkugeln werden aufgrund ihrer Härte und Verschleißfestigkeit häufig in Hochgeschwindigkeits- und Hochpräzisionsmaschinen, Motoren und Triebwerken eingesetzt.

- Schleifen von Anwendungen: Zirkoniumdioxid-Keramikkugeln eignen sich hervorragend zum Schleifen keramikMagnetische Materialien, Beschichtungen und Druckfarben, die eine hervorragende Leistung bei Mahl- und Dispersionsprozessen bieten.

- Chemische und pharmazeutische Industrie: Sie werden in der Lebensmittel-, Pharma- und Spezialchemieindustrie häufig zum Mahlen, Mischen und Vermengen von Materialien eingesetzt.

- Medizinische Anwendungen: Zirkoniumdioxid-Keramikkugeln werden aufgrund ihrer Biokompatibilität, Festigkeit und Korrosionsbeständigkeit in medizinischen Geräten, einschließlich Zahnimplantaten und Prothetik, verwendet.

Materialeigenschaften von Zirkoniumdioxid

Zirkoniumdioxid Werkstoffklassen

Ultra Tough Grade ist ein hochentwickeltes Zirkoniumdioxid-Keramikkompositmaterial, das teilstabilisiertes Zirkoniumdioxid mit einer verbesserten Kristallstruktur kombiniert, um außergewöhnliche mechanische Eigenschaften zu erzielen.

Allgemeine Eigenschaften

- Arbeitet bei Temperaturen bis zu 1500°C

- Vollständig gesintert für eine porenfreie Struktur

- Hohe Bruchzähigkeit und Schlagfestigkeit ohne Beeinträchtigung der Biegefestigkeit oder Härte

- Erhöhter Widerstand gegen Rissausbreitung aufgrund seiner einzigartigen Mikrostruktur

- Erhöhte Beständigkeit gegen hydrothermale Alterung durch partielle Stabilisierung mit Ceroxid

Anwendungen

- Hochdruckgeräte wie Kugelhahnkugeln und -sitze

- Ultra-Hochdruck-Pumpenelemente

- Durchflussregelgeräte für Hochdruckgeräte wie Homogenisatoren

- Tiefbohrlochventile und -sitze

- Walzen und Führungen für die Metallumformung

Ultra Tough HIP Grade ist ein hochmoderner Verbundwerkstoff, der durch Heiß-Isostatisches Pressen (HIP) eine überragende Festigkeit, Zähigkeit und Zuverlässigkeit erreicht hat und damit ideal für anspruchsvolle Anwendungen ist.

Allgemeine Eigenschaften

- Arbeitet bei Temperaturen bis zu 1500°C

- HIP-verarbeitet für außergewöhnliche Stärke und Konsistenz

- Hohe Bruchzähigkeit kombiniert mit ausgezeichneter Biegefestigkeit und Härte

- Hervorragende Rissverformungseigenschaften in einer teilstabilisierten Zirkoniumdioxidmatrix

- Verbesserte Beständigkeit gegen hydrothermale Alterung durch partielle Stabilisierung mit Ceroxid

Anwendungen

- Hochdruckausrüstung wie Ventilkugeln und -sitze

- Ultra-Hochdruck-Pumpenelemente

- Durchflussregelungskomponenten für Hochdruckhomogenisatoren

- Tiefbohrlochventile und -sitze

- Walzen und Führungen für die Metallumformung

Die Keramiksorte 3YZ, die auf 3 mol % Yttria Partially Stabilized Zirconia (3YSZ) basiert, bietet eine feinere Kornstruktur für verbesserte mechanische Eigenschaften und hervorragende Isotropie.

Allgemeine Eigenschaften

- Arbeitet bei Temperaturen bis zu 1000°C

- Niedrige Wärmeleitfähigkeit für Temperaturstabilität

- Ausgezeichnete chemische Beständigkeit, insbesondere in Umgebungen mit geschmolzenem Metall

- Hohe Verschleißfestigkeit und Bruchzähigkeit

- Hohe Härte für anspruchsvolle mechanische Anwendungen

Anwendungen

- Hochdruckgeräte wie Kugelhahnkugeln und -sitze

- Ultra-Hochdruck-Pumpenelemente

- Durchflussregelgeräte für Hochdruckhomogenisatoren

- Tiefbohrlochventile und -sitze

- Walzen und Führungen für die Metallumformung

Nano HIP Grade besteht aus 3 mol % Yttria Partially Stabilized Zirconia (3YSZ) mit einem ultrafeinen Korngefüge, das durch Heiß-Isostatisches Pressen (HIP) verdichtet wurde, um außergewöhnliche Zuverlässigkeit und Leistung zu gewährleisten.

Allgemeine Eigenschaften

- Arbeitet bei Temperaturen bis zu 1000°C

- Geringe Wärmeleitfähigkeit für besseres Wärmemanagement

- Hervorragende chemische Beständigkeit, insbesondere in geschmolzenen Metallen

- Hohe Verschleißfestigkeit und ausgezeichnete Bruchzähigkeit

- Ultrafeine Kornstruktur für hohe Härte und überragende Leistung

Anwendungen

- Hochdruckgeräte wie Ventilkugeln und -sitze

- Ultra-Hochdruck-Pumpenelemente

- Durchflussregelungskomponenten für Hochdruckhomogenisatoren

- Tiefbohrlochventile und -sitze

- Walzen und Führungen für die Metallumformung

Zirkoniumdioxid-Keramik-Bearbeitung

Zirkoniumdioxid, eine Hochleistungskeramik, ist bekannt für seine Zähigkeit, Härte und Verschleißfestigkeit und damit ideal für Anwendungen, die eine hohe mechanische Festigkeit und thermische Stabilität erfordern. Die Bearbeitung von Zirkoniumdioxid kann jedoch aufgrund seiner Härte und Zähigkeit schwierig sein und erfordert je nach Bearbeitungszustand unterschiedliche Methoden.

Bearbeitung von Zirkoniumdioxid in verschiedenen Staaten:

- Grün und Keksform: Vor dem Sintern leichter zu bearbeiten, aber enge Toleranzen können aufgrund der Schrumpfung während des Sinterns nicht eingehalten werden.

- Vollständig gesintertes Zirkoniumdioxid: Wird hart und dicht und erfordert für präzise Formen das Schleifen oder Schneiden mit Diamant.

Gängige Bearbeitungsverfahren:

- CNC-Bearbeitung: Wird für komplexe Formen verwendet, oft mit Diamantwerkzeugen.

- Diamant-Schleifen: Für präzise Abmessungen und Oberflächengüte.

- Diamantschneiden und -sägen: Spezielle Diamantwerkzeuge verhindern Rissbildung.

- Polieren: Glättet Oberflächen, insbesondere für medizinische oder Präzisionsanwendungen.

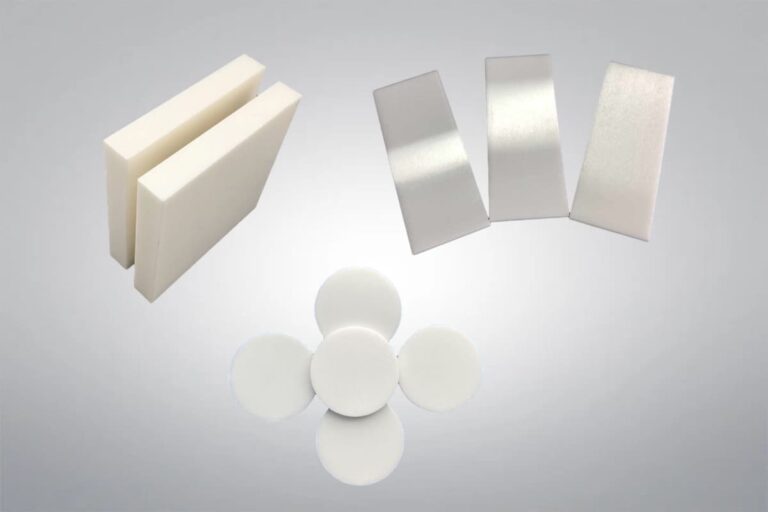

Zirkoniumdioxid-Keramik-Verpackungen

Zirkoniumdioxid-Keramikprodukte werden in der Regel in vakuumversiegelten Beuteln verpackt, um Feuchtigkeit oder Verunreinigungen zu vermeiden, und mit Schaumstoff umwickelt, um Erschütterungen und Stöße während des Transports zu dämpfen und die Qualität der Produkte im Originalzustand zu gewährleisten.

Herunterladen

Angebot einholen

Wir werden das prüfen und uns innerhalb von 24 Stunden bei Ihnen melden.