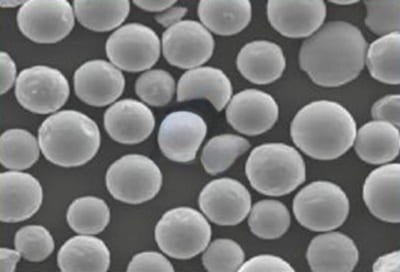

Yttriumoxid-stabilisiertes kugelförmiges Zirkoniumdioxid-Pulver

Yttriumoxid-stabilisiertes kugelförmiges Zirkoniumdioxid-Pulver

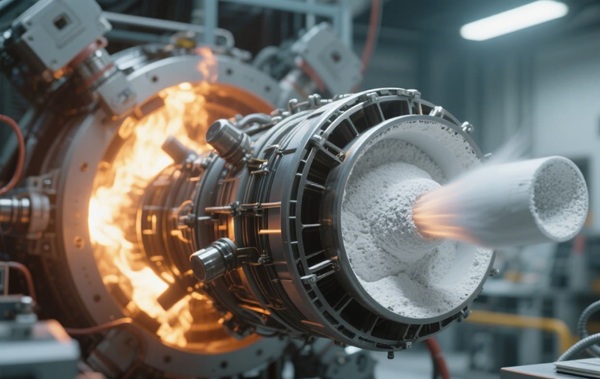

Yttriumoxid-stabilisiertes kugelförmiges Zirkoniumdioxid-Pulver ist ein thermisch stabiles keramisches Material, das für Beschichtungsanwendungen bei hohen Temperaturen entwickelt wurde. Es besteht aus Zirkoniumdioxid (ZrO₂), das mit 8% Yttriumoxid (Y₂O₃) stabilisiert ist, und weist eine kugelförmige Morphologie auf, die ideal für das thermische Spritzen ist. Das Pulver bietet eine ausgezeichnete Temperaturwechselbeständigkeit, eine niedrige Wärmeleitfähigkeit und eine hohe Phasenstabilität bei schnellen Temperaturschwankungen. Es wird häufig in der Luft- und Raumfahrt sowie in der Energietechnik eingesetzt und bietet einen wirksamen Wärmeschutz für Turbinenschaufeln, Brennkammern und Raketenkomponenten, die bei Temperaturen von bis zu 1250 °C arbeiten. Wir können hochwertiges yttriumoxidstabilisiertes Zirkoniumdioxidpulver mit verschiedenen Spezifikationen und zu wettbewerbsfähigen Preisen liefern und bieten maßgeschneiderte Lösungen für spezifische Anforderungen.

Oder senden Sie uns eine E-Mail an sales@heegermaterials.com.Yttriumoxid-stabilisiertes kugelförmiges Zirkoniumdioxid-Pulver Datenblatt

| Hauptzusammensetzung: | 92% ZrO2-8%Y2O3 |

| Farbe: | Weiß |

| Herstellungsprozess: | Agglomerierte Sinterung |

| Erscheinungsbild: | Sphärische Partikel |

| Partikelgröße: | -75/+45 μm, -75/+20 μm, -63/+22 μm, -45/+15 μm, oder kundenspezifisch |

Yttriumoxid-stabilisiertes kugelförmiges Zirkoniumdioxid-Pulver Beschreibung

Yttriumoxid-stabilisiertes kugelförmiges Pulver ist ein präzisionsgefertigtes Keramikpulver, das für eine gleichbleibende Leistung bei Plasma- und Flammspritzanwendungen entwickelt wurde. Seine perfekt kugelförmigen Partikel sorgen für einen gleichmäßigen Pulverfluss und eine gleichmäßige Abscheidung, wodurch es sich ideal für die Herstellung dichter, haftender Beschichtungen eignet. Die stabilisierte Zirkoniumdioxidstruktur widersteht dem Phasenabbau und bewahrt die mechanische Integrität unter extremer thermischer Belastung. Dies macht es zu einer zuverlässigen Wahl für Schutzbeschichtungen in Gasturbinen, Hochgeschwindigkeitsbauteilen in der Luft- und Raumfahrt und thermischen Abschirmsystemen, die schnellen Heiz- und Kühlzyklen ausgesetzt sind.

Yttriumoxid-stabilisiertes kugelförmiges Zirkoniumdioxid-Pulver Spezifikationen

| Partikelgröße (μm) | ZrO2+HfO2(wt.%) | Y2O3(wt.%) | Verunreinigungen (wt.%) |

| -75/+45 | >91% | 6.5-8.5% | CaO: <0.05%SiO2: <0.02%Fe2O3: <0.01% |

| -75/+20 | |||

| -63/+22 | |||

| -45/+15 |

Yttriumoxid-stabilisiertes kugelförmiges Zirkoniumdioxid-Pulver Merkmale

- Ausgezeichnete Temperaturwechselbeständigkeit: Bewahrt die strukturelle Stabilität bei schnellen Temperaturschwankungen, ideal für Wärmedämmschichten in extremen Umgebungen.

- Stabile Phasenzusammensetzung: Das teilweise mit 8%-Yttriumoxid stabilisierte Pulver weist eine Mischung aus kubischen und tetragonalen Phasen auf, die eine unerwünschte Umwandlung bei hohen Temperaturen verhindert.

- Morphologie kugelförmiger Partikel: Gleichmäßig runde Partikel verbessern die Fließfähigkeit und die Gleichmäßigkeit der Beschichtung beim thermischen Spritzen.

- Hohe Verschleiß- und Korrosionsbeständigkeit: Bietet eine hohe Beständigkeit gegen Erosion, Oxidation und korrosive Gase bei hohen Temperaturen und verlängert die Lebensdauer der Beschichtung.

- Niedrige Wärmeleitfähigkeit: Isoliert wirksam die darunter liegenden Substrate und schützt Metallteile in Hochtemperaturbereichen wie Turbinen und Raketentriebwerken.

Yttriumoxid-stabilisiertes kugelförmiges Zirkoniumdioxid-Pulver Anwendungen

- Wärmedämmschichten (TBCs): Wird in Düsentriebwerken, Turbinen und Brennkammern verwendet, um Metallteile vor extremer Hitze zu schützen.

- Komponenten für die Luft- und Raumfahrt: Wird auf Tragflächen, Flammrohren und Abgasdüsen zur Isolierung und zum Schutz vor thermischer Ermüdung eingesetzt.

- Ausrüstung für den Energiesektor: Schützt Oberflächen in industriellen Hochtemperaturprozessen, einschließlich Plasmaöfen und Heizkesseln.

- Turbolader für Kraftfahrzeuge: Wirkt als Hitzeschutzschicht in Hochleistungsmotoren.

- Raketenantriebsysteme: Dient als wichtiges Isoliermaterial in Düsen- und Verbrennungszonenbeschichtungen.

Yttriumoxid-stabilisiertes kugelförmiges Zirkoniumdioxid-Pulver Verpackung

Yttriumoxid-stabilisiertes, kugelförmiges Zirkoniumdioxid-Pulver wird in der Regel in versiegelten, feuchtigkeitsdichten Kunststoffbeuteln verpackt und dann in robuste Fassbehälter oder Faserkartons gelegt, um eine Kontamination zu verhindern und einen sicheren Transport zu gewährleisten. Zu den Standardverpackungsgrößen gehören 1 kg, 5 kg und 10 kg, wobei auf Anfrage auch kundenspezifische Verpackungen erhältlich sind, um spezielle Verwendungs- oder Lagerungsanforderungen zu erfüllen.

Herunterladen

Angebot einholen

Wir werden das prüfen und uns innerhalb von 24 Stunden bei Ihnen melden.