PZT-Pulver

PZT-Pulver

PZT-Pulver ist ein hochleistungsfähiges piezoelektrisches Keramikmaterial, das sowohl für harte als auch für weiche piezoelektrische Anwendungen geeignet ist und eine hervorragende elektromechanische Kopplung, Stabilität und abstimmbare Eigenschaften bietet. Es eignet sich für Unterwasserwandler, Sensoren, Ultraschallgeräte und Aktoren und bietet zuverlässige Leistung für fortschrittliche piezoelektrische Komponenten. Wir können hochwertiges PZT-Pulver mit verschiedenen Spezifikationen und zu wettbewerbsfähigen Preisen liefern und kundenspezifische Lösungen für spezifische Anforderungen anbieten.

Oder senden Sie uns eine E-Mail an sales@heegermaterials.com.Datenblatt PZT-Pulver

| Material: | Blei-Zirkonat-Titanat (PZT) |

| Farbe: | Weiß bis cremefarben |

| Partikelgröße : | Kundenspezifisch |

PZT-Pulver Beschreibung

PZT-Pulver ist ein hochleistungsfähiges Basismaterial für fortschrittliche piezoelektrische Bauteile, das mit präziser Zusammensetzungskontrolle und Mikrostrukturtechnik hergestellt wird, um hervorragende piezoelektrische, dielektrische und stabile Eigenschaften zu erzielen. Basierend auf dem Blei-Zirkonat-Titanat (PZT)-System wird seine Kristallstruktur durch Phasengrenzregulierung und Dotierung optimiert, um eine hohe elektromechanische Kopplung und geringe Verluste zu gewährleisten. Harte PZT-Pulver zeichnen sich durch dichte Korngrenzen für eine verbesserte Festigkeit und Leistungsaufnahme aus. Modelle wie HMP42, HMP44 und HMP46 bieten Dielektrizitätskonstanten von 1200-1380 und kp≥0,59. Weiche PZT-Pulver verbessern die Gitterflexibilität durch ionische Dotierung und erreichen Dielektrizitätskonstanten bis zu 4500, große piezoelektrische Dehnungen (d33≥680×10-¹² C/N) und kt bis zu 0,78, wie bei HMP5A, HMP51 und HMP5H. PZT-Pulver eignet sich für Unterwasserwandler, Ultraschallgeräte, Sensoren und Präzisionsantriebe und ist die ideale Wahl für hocheffiziente, leistungsstarke piezoelektrische Komponenten.

Technische Spezifikationen für PZT-Pulver

PZT-Pulver Eigenschaften

- Anpassbare Leistung: Deckt das gesamte Spektrum von hartem bis weichem PZT ab, mit Gradientenparametern, die den Anforderungen der Geräte genau entsprechen.

- Ausgezeichnete Prozesskompatibilität: Erhältlich sowohl im konventionellen Sinterverfahren (≈1260 °C) als auch im Niedertemperatursinterverfahren (bis zu 985 °C), das mehrschichtige monolithische Strukturen und die Integration komplexer Bauelemente unterstützt.

- Hervorragende piezoelektrische und dielektrische Eigenschaften: Hohe elektromechanische Kopplungseffizienz, stabile Dielektrizitätskonstante und geringer Verlust über einen breiten Frequenzbereich.

- Hohe thermische Stabilität: Der Curie-Temperaturbereich (Tc) von 200-320 °C gewährleistet einen zuverlässigen Betrieb über ein breites Temperaturspektrum.

- Hohe Reinheit und Qualitätssicherung: Strenge Herstellungs- und Qualitätskontrollstandards garantieren eine konstante Partikelgröße, eine gleichmäßige Sinterung und eine reproduzierbare Leistung.

PZT-Pulver Anwendungen

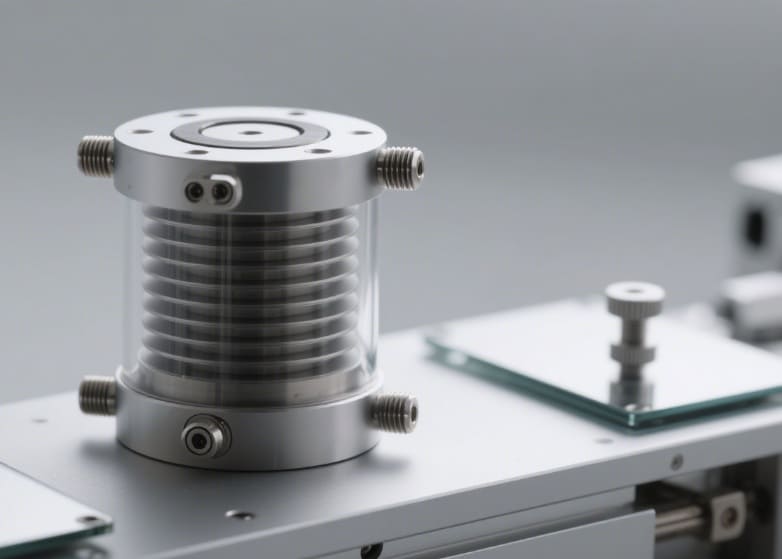

- Hochleistungs-Ultraschallgeräte (harte PZT): Geeignet für Ultraschallreinigungs- und -zerstäubungswandler (z. B. HMP44), akustische Unterwassererkennungssensoren (z. B. HMP42) und Hochleistungsschweiß-/Emulgiergeräte (z. B. HMP8).

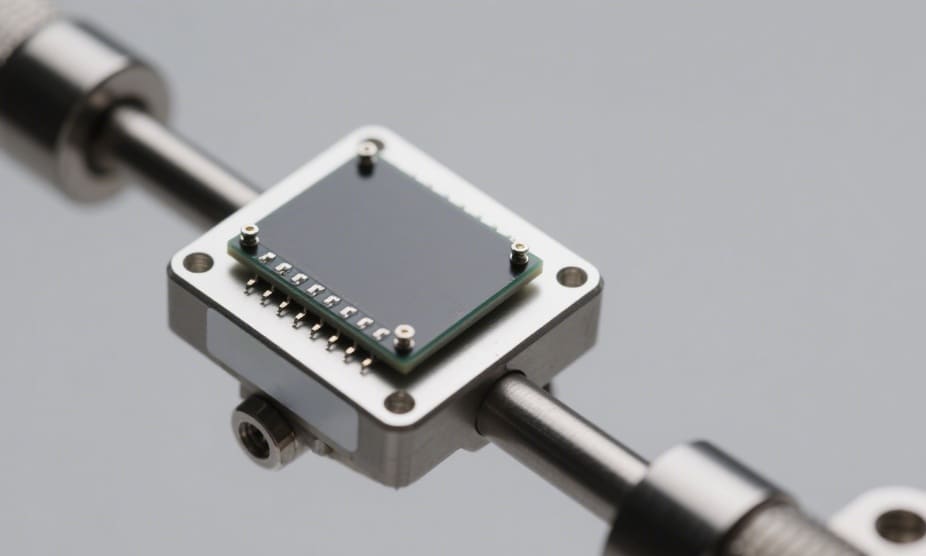

- Präzisionsbetätigung (Soft PZT): Anwendung in hochpräzisen piezoelektrischen Aktoren (z. B. HMP5H) für Optik, Positionierung und Mikrobewegungssysteme.

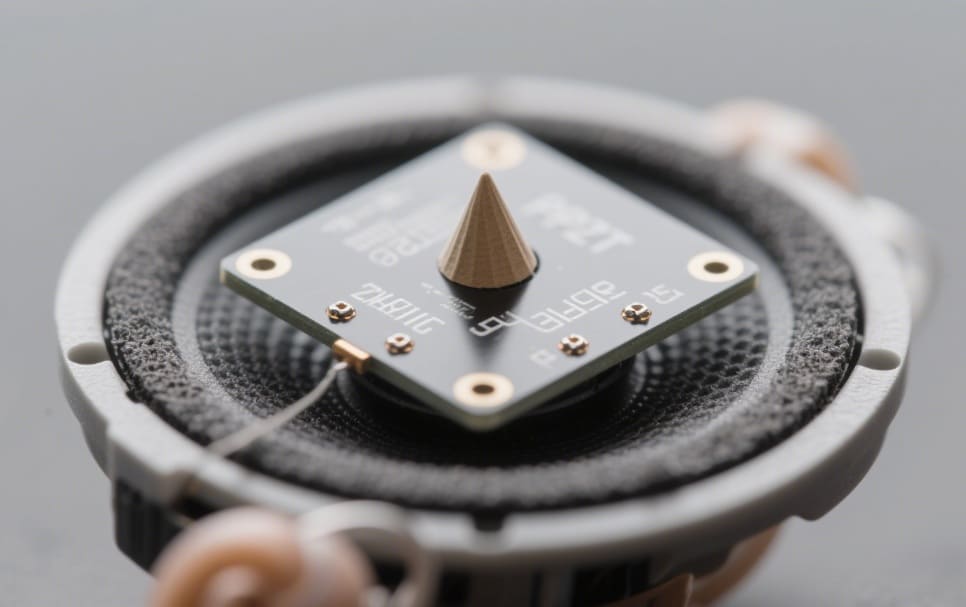

- Hochempfindliche Sensorik: Ideal für Hydrophone und Sonarempfänger (z. B. HMP5A) sowie hochempfindliche Empfänger (z. B. HMP51) in akustischen Messsystemen.

- Energieumwandlung und -ernte: Wandelt mechanische Schwingungen in elektrische Energie für energieautarke Geräte und drahtlose Sensoren mit niedrigem Energieverbrauch um.

- RF- und Kommunikationskomponenten: Integriert in Resonatoren und Filter zur stabilen Frequenzregelung in HF- und Mikrowellenkommunikationsgeräten.

PZT-Pulver-Verpackungen

PZT-Pulver wird in der Regel in versiegelten, feuchtigkeitsdichten Kunststoffbeuteln verpackt und dann in robuste Fassbehälter oder Faserkartons gelegt, um Verunreinigungen zu vermeiden und einen sicheren Transport zu gewährleisten. Zu den Standardverpackungsgrößen gehören 1 kg, 5 kg und 10 kg, wobei auf Anfrage auch kundenspezifische Verpackungen erhältlich sind, um spezifische Verwendungs- oder Lagerungsanforderungen zu erfüllen.

Herunterladen

Angebot einholen

Wir werden das prüfen und uns innerhalb von 24 Stunden bei Ihnen melden.