Zirconia estabilizada con itria Polvo esférico

Zirconia estabilizada con itria Polvo esférico

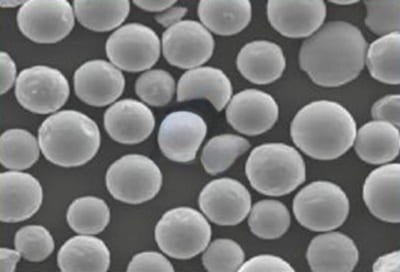

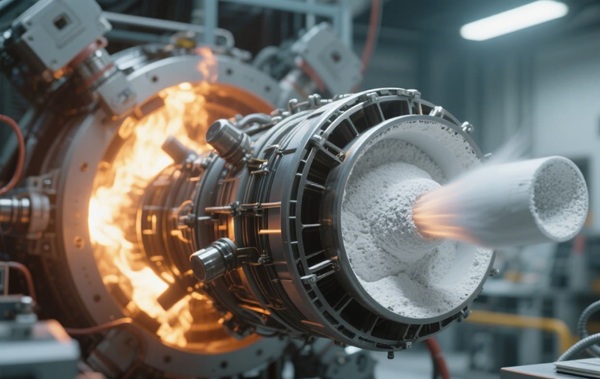

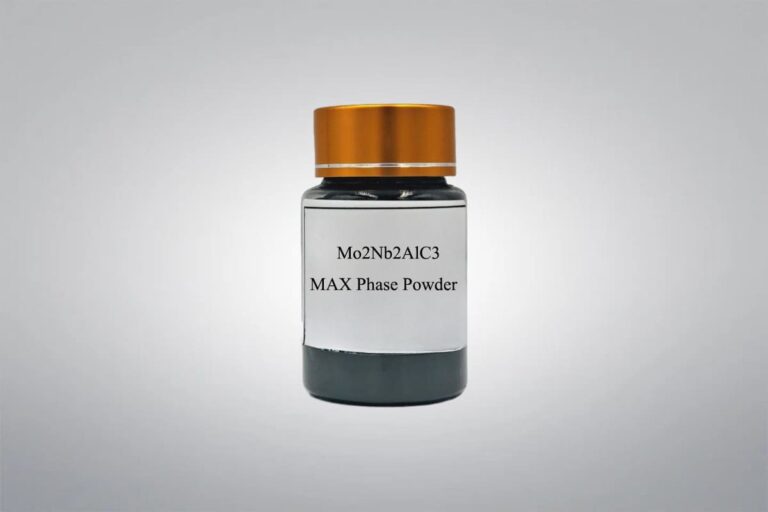

Zirconia estabilizada con itria Polvo esférico es un material cerámico térmicamente estable diseñado para aplicaciones de revestimiento a alta temperatura. Compuesto de circonio (ZrO₂) estabilizado con itria 8% (Y₂O₃), presenta una morfología esférica ideal para la pulverización térmica. El polvo ofrece una excelente resistencia al choque térmico, una baja conductividad térmica y una gran estabilidad de fase bajo rápidas fluctuaciones de temperatura. Ampliamente utilizado en sistemas aeroespaciales y energéticos, proporciona una eficaz protección de barrera térmica para álabes de turbina, cámaras de combustión y componentes de cohetes que funcionan a temperaturas de hasta 1250°C. Podemos suministrar polvo de circonio estabilizado con itria de alta calidad con diversas especificaciones y precios competitivos, ofreciendo soluciones personalizadas para satisfacer requisitos específicos.

O envíenos un correo electrónico a sales@heegermaterials.com.Ficha técnica del polvo esférico de óxido de circonio estabilizado con itria

| Composición principal: | 92% ZrO2-8%Y2O3 |

| Color: | Blanco |

| Proceso de fabricación: | Sinterización aglomerada |

| Apariencia: | Partículas esféricas |

| Tamaño de las partículas: | -75/+45 μm, -75/+20 μm, -63/+22 μm, -45/+15 μm, o personalizado. |

Zirconia estabilizada con itria Polvo esférico Descripción

Polvo esférico estabilizado con itria es un polvo cerámico de ingeniería de precisión diseñado para un rendimiento constante en aplicaciones de proyección de plasma y llama. Sus partículas perfectamente esféricas garantizan un flujo de polvo suave y una deposición uniforme, por lo que es ideal para crear revestimientos densos y adherentes. La estructura estabilizada de la zirconia resiste la degradación de fases y mantiene la integridad mecánica bajo tensiones térmicas extremas. Esto la convierte en una opción fiable para revestimientos protectores en turbinas de gas, conjuntos aeroespaciales de alta velocidad y sistemas de blindaje térmico expuestos a ciclos rápidos de calentamiento y enfriamiento.

Especificaciones del polvo esférico de circonio estabilizado con itria

| Tamaño de las partículas (μm) | ZrO2+HfO2(peso.%) | Y2O3(peso.%) | Impurezas (peso.%) |

| -75/+45 | >91% | 6.5-8.5% | CaO: <0.05%SiO2: <0.02%Fe2O3: <0.01% |

| -75/+20 | |||

| -63/+22 | |||

| -45/+15 |

Zirconia estabilizada con itria Polvo esférico Características

- Excelente resistencia al choque térmico: Mantiene la estabilidad estructural bajo rápidas fluctuaciones de temperatura, ideal para revestimientos de barrera térmica en entornos extremos.

- Composición de la fase estable: Parcialmente estabilizado con itria 8%, el polvo conserva una mezcla de fases cúbicas y tetragonales que evitan transformaciones no deseadas a altas temperaturas.

- Morfología de las partículas esféricas: Las partículas uniformemente redondas mejoran la fluidez y la uniformidad del revestimiento en los sistemas de proyección térmica.

- Alta resistencia al desgaste y a la corrosión: Ofrece una gran resistencia a la erosión, la oxidación y los gases corrosivos a temperaturas elevadas, prolongando la vida útil del revestimiento.

- Baja conductividad térmica: Aísla eficazmente los sustratos subyacentes, protegiendo los componentes metálicos en condiciones de alto calor, como turbinas y motores de cohetes.

Zirconia estabilizada con itria Polvo esférico Aplicaciones

- Revestimientos de barrera térmica (TBC): Se utiliza en motores a reacción, turbinas y cámaras de combustión para proteger los componentes metálicos del calor extremo.

- Componentes aeroespaciales: Se aplica a las superficies de las alas, los tubos de llama y las toberas de escape para el aislamiento y la resistencia a la fatiga térmica.

- Equipamiento del sector energético: Protege superficies en procesos industriales a alta temperatura, incluidos hornos de plasma y calderas.

- Turbocompresores de automoción: Actúa como revestimiento protector del calor en motores de alto rendimiento.

- Sistemas de propulsión de cohetes: Sirve como material aislante clave en los revestimientos de toberas y zonas de combustión.

Zirconia estabilizada con itria Envasado de polvo esférico

El polvo esférico de óxido de circonio estabilizado con itria suele envasarse en bolsas de plástico selladas a prueba de humedad y, a continuación, se coloca en resistentes bidones o cajas de fibra para evitar la contaminación y garantizar un transporte seguro. Los tamaños de envasado estándar incluyen opciones de 1 kg, 5 kg y 10 kg, con envases personalizados disponibles bajo pedido para satisfacer necesidades específicas de uso o almacenamiento.

Descargar

Solicitar presupuesto

Lo comprobaremos y le responderemos en 24 horas.