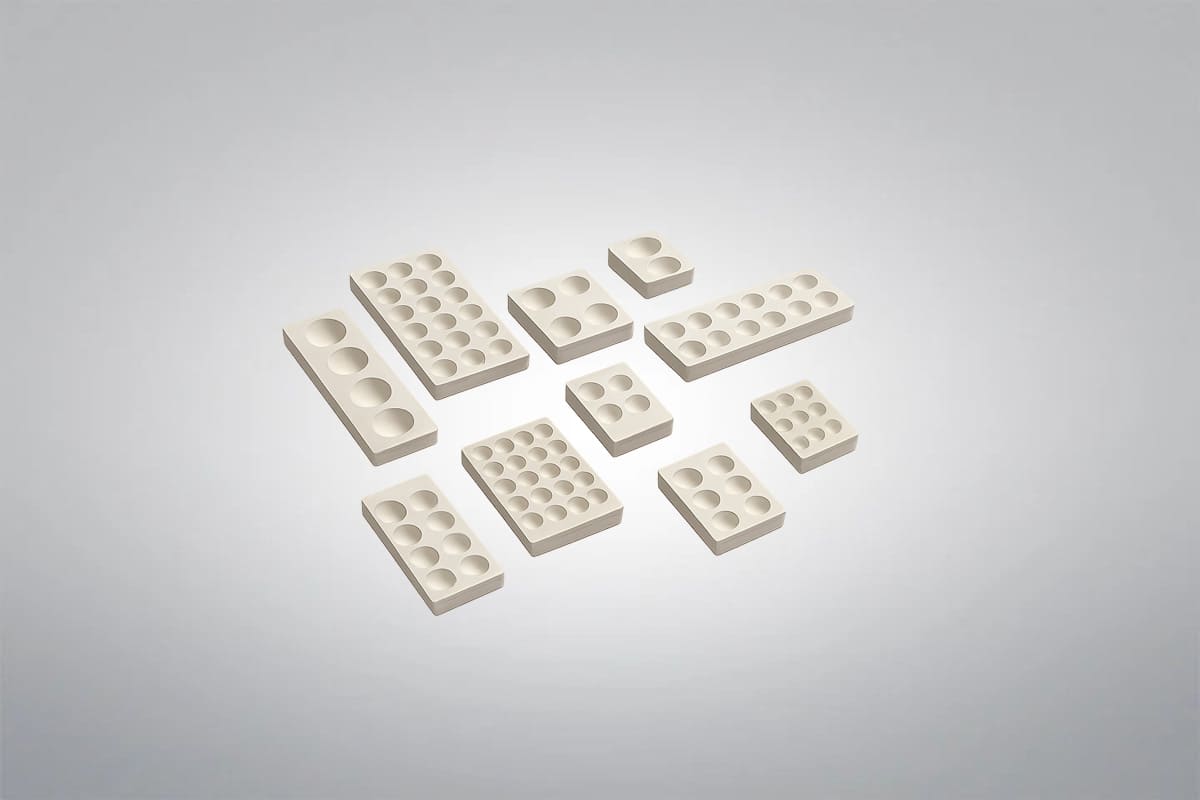

Magnesium Oxide Cupel Block

Magnesium Oxide Cupel Block

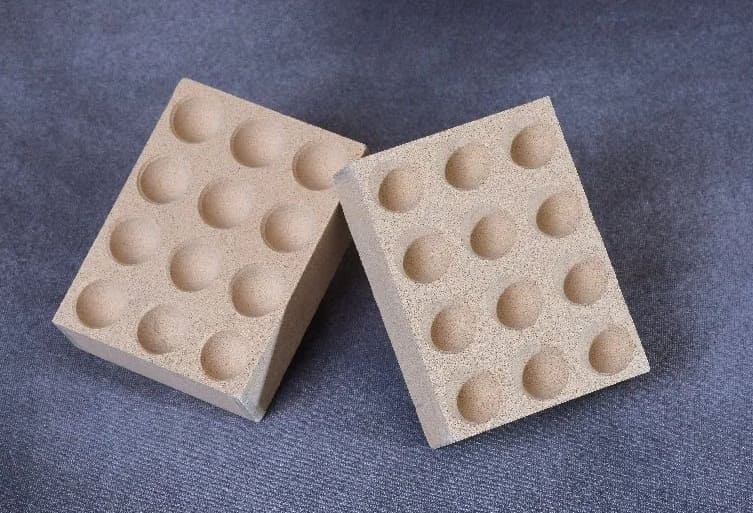

Magnesium Oxide Cupel Block is a high-purity refractory material designed for fire assay, precious metal refining, and industrial metallurgical applications. Made from premium magnesium oxide with a controlled formulation, it offers excellent lead oxide absorption, superior thermal stability, and strong mechanical strength. The block maintains integrity under high-temperature cupellation, resisting cracking, pitting, and deformation, while ensuring efficient separation of gold and silver from impurities. Its durable structure allows for repeated use and long-term storage without quality degradation. We can supply high-quality magnesium oxide cupel blocks with various specifications and competitive prices, offering customized solutions to meet specific requirements.

O envíenos un correo electrónico a sales@heegermaterials.com.Magnesium Oxide Cupel Block Data Sheet

| Color | Yellow, Light yellow, or White |

| Materiales | MgO |

| Pureza | 96% min |

Magnesium Oxide Cupel Block Description

Magnesium Oxide Cupel Block is a monolithic refractory block made from high-purity and high-density magnesium oxide, featuring multiple precisely formed cavities for simultaneous cupellation operations. Each cavity functions as an independent reaction chamber, enabling accurate and efficient fire assay of precious metals. During use, the block quickly absorbs large quantities of lead oxide without splashing or cracking, leaving high-purity gold and silver alloy grains. It maintains excellent structural integrity under extreme temperatures and remains stable against humidity and freezing conditions. After cupellation, the metallic grains can be easily separated from the cavities.

Magnesium Oxide Cupel Block Specifications

| Tipo | Agujero | Hole(Length Direction) | Hole(Width Direction) | a (mm) | b (mm) | c (mm) | d (mm) |

| 4 HB | 4 | 2 | 2 | 4 | 4 | 4 | 4 |

| 4 SAHB | 4 | 2 | 2 | 5 | 5 | 6 | 6 |

| 6 HB | 6 | 3 | 2 | 2.5 | 2.5 | 5 | 5 |

| 6 HB(T) | 6 | 3 | 2 | 5.25 | 4 | 5.5 | 4 |

| 10 HB | 10 | 5 | 2 | 5 | 5 | 6 | 4.5 |

| 12 HB | 12 | 4 | 3 | 3 | 3 | 6 | 6 |

| 12 HB(L) | 12 | 6 | 2 | 5.25 | 5.25 | 5.5 | 4.5 |

| 14 HB | 14 | 7 | 2 | 3 | 3 | 2 | 2 |

| 21 HB | 21 | 7 | 3 | 3 | 3 | 2 | 2 |

| 24 HB | 24 | 6 | 4 | 4 | 4 | 4 | 4 |

| 24 HB(L) | 24 | 6 | 4 | 5.5 | 4 | 5.5 | 5.6 |

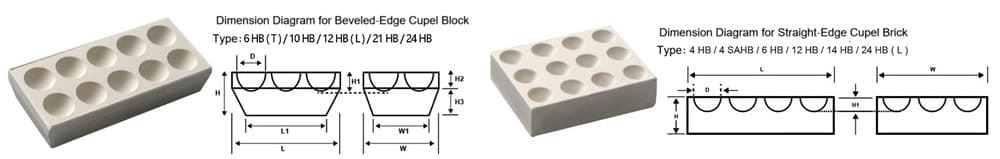

Magnesium Oxide Cupel Block Specifications (Bevel-Edge and Straight-Edge)

| Tipo | Agujero | Longitud | Anchura | Altura | Diameter of Hole | Depth of Hole | Ridge Height | Bevel-Edge Height | Weight (Approx.) | ||

| L | L1 | W | W1 | H | D | H1 | H2 | H3 | g | ||

| 4 HB | 4 | 48 | — | 48 | — | 20 | 18 | 6.5 | — | — | 97 |

| 4 SAHB | 4 | 80 | — | 80 | — | 26 | 30 | 9 | — | — | 321 |

| 6 HB | 6 | 76.5 | — | 51 | — | 20 | 20.5 | 8 | — | — | 150 |

| 6 HB(T) | 6 | 82 | 72 | 60 | 50 | 20 | 22 | 7 | 6 | 14 | 184 |

| 10 HB | 10 | 138 | 128 | 60 | 50 | 20 | 22 | 7 | 6 | 14 | 307 |

| 12 HB | 12 | 80 | — | 60 | — | 20 | 14 | 7 | — | — | 204 |

| 12 HB(L) | 12 | 165 | 155 | 60 | 50 | 20 | 22 | 7 | 6 | 14 | 375 |

| 14 HB | 14 | 179 | — | 54 | — | 20 | 20 | 7.5 | — | — | 367 |

| 21 HB | 21 | 172 | 162 | 76 | 66 | 20 | 22 | 7 | 6 | 14 | 476 |

| 24 HB | 24 | 124 | 114 | 84 | 74 | 20 | 16 | 7 | 6 | 14 | 402 |

| 24 HB(U) | 24 | 165 | — | 120 | — | 20 | 21.5 | 7 | — | — | 830 |

Magnesium Oxide Cupel Block Features

- High-Purity Raw Materials: Manufactured using premium-grade magnesium oxide and advanced formulations to ensure consistent density, purity, and absorption performance.

- Uniform Structure and Smooth Surface: Each block features a precisely formed surface with clean, well-defined cavities for accurate and efficient cupellation.

- Exceptional Mechanical Strength and Thermal Stability: Withstands repeated high-temperature use without cracking, warping, or pitting, ensuring long-lasting durability.

- Stable Against Environmental Conditions: Resistant to moisture, temperature fluctuations, and freezing, maintaining stable quality during long-term storage.

- Efficient Lead Oxide Absorption: Capable of rapidly absorbing large amounts of lead oxide—up to about 70% of its own weight—ensuring minimal loss of precious metals.

- Advanced Production and Quality Control: Manufactured using modern machinery under ISO 9001-certified systems, with ongoing laboratory testing to guarantee consistent product quality.

Magnesium Oxide Cupel Block Applications

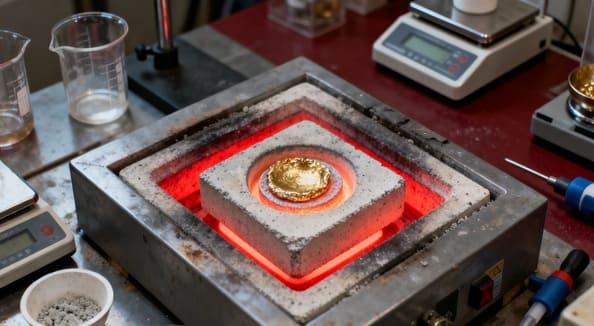

- Fire Assay Analysis: Used in laboratories for determining precious metal content in ores, concentrates, and alloys through the cupellation process.

- Gold and Silver Refining: Efficiently separates precious metals from lead and other impurities, ensuring accurate recovery of high-purity gold and silver.

- Mining and Metallurgical Testing: Essential for quality control and assay testing in mining operations, smelting plants, and metal refining facilities.

- Analytical Laboratories: Applied in research and testing institutions for reliable quantitative analysis of noble metals.

- Industrial Quality Assurance: Used in production environments where precise metal content verification is required for raw materials and finished products.

Magnesium Oxide Material Properties

Mecanizado cerámico de óxido de magnesio

El óxido de magnesio puede mecanizarse en estado verde o bizcocho antes de la sinterización y, en menor medida, en su estado totalmente sinterizado. En su estado presinterizado, el material es relativamente blando y más fácil de moldear, pero como muchas cerámicaEl óxido de magnesio sinterizado es muy duro y quebradizo, por lo que requiere herramientas de diamante y equipos de precisión para cualquier mecanizado posterior a la sinterización. El óxido de magnesio totalmente sinterizado es muy duro y quebradizo, por lo que requiere herramientas de diamante y equipos de precisión para cualquier mecanizado posterior a la sinterización.

Métodos de mecanizado y consideraciones

- Mecanizado en verde o bizcocho: Más fácil de cortar y moldear, adecuado para formas complejas antes de la cocción.

- Contracción por sinterización: Se espera una reducción dimensional de unos 15-20% durante la sinterización, lo que repercute en el control de la tolerancia.

- Mecanizado posterior a la sinterización: Requiere herramientas de rectificado de diamante debido a la dureza y fragilidad del material.

- Fragilidad: El MgO totalmente sinterizado es propenso a astillarse y fracturarse si no se manipula con cuidado durante el mecanizado.

- Herramientas y tiempo: El mecanizado de cerámicas densas de MgO requiere mucho tiempo y equipos especializados.

Envases cerámicos de óxido de magnesio

Los productos cerámicos de óxido de magnesio suelen envasarse en bolsas selladas al vacío para evitar la humedad o la contaminación y se envuelven con espuma para amortiguar las vibraciones y los impactos durante el transporte, lo que garantiza la calidad de los productos en su estado original.

Descargar

Solicitar presupuesto

Lo comprobaremos y le responderemos en 24 horas.