Pyrolytisches Bornitrid-Heizgerät

Pyrolytisches Bornitrid-Heizgerät

Werkstoff: PBN-PG-PBN

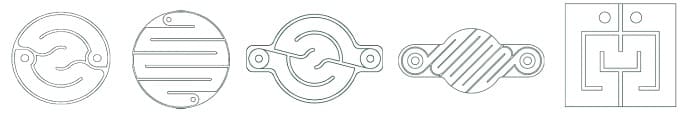

Durchmesser: 0,5-5 Zoll

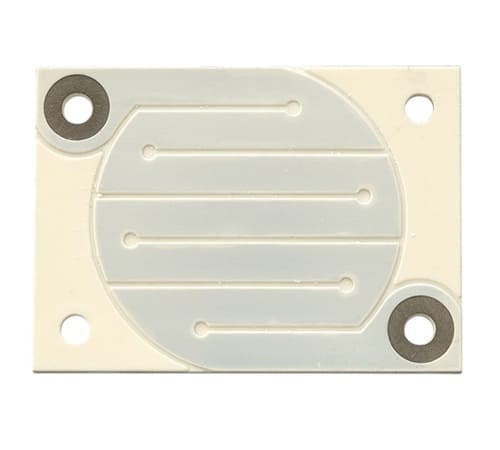

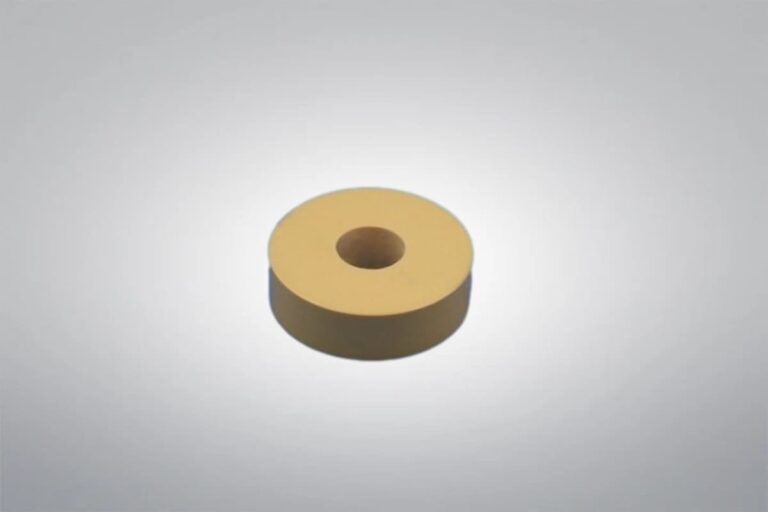

Das Heizelement aus pyrolytischem Bornitrid ist ein Hochleistungsheizelement für Hochtemperatur-, Hochvakuum- und hochreine Prozesse. Er besteht aus einem Substrat aus pyrolytischem Bornitrid (PBN) und einer leitfähigen Heizschicht aus apyrolytischem Graphit (PG) und wird durch chemische Gasphasenabscheidung (CVD) hergestellt. Als führender Anbieter und Hersteller von hochwertigen Produkten aus pyrolytischem Bornitrid können wir hochwertige PBN/PG-Heizer mit verschiedenen Spezifikationen und zu wettbewerbsfähigen Preisen liefern und kundenspezifische Lösungen für spezifische Anforderungen anbieten.

Oder senden Sie uns eine E-Mail an sales@heegermaterials.com.Datenblatt Pyrolytisches Bornitrid-Heizgerät

| Referenz: | PBN1277 |

| Material: | PBN-PG-PBN |

| Reinheit: | 99.99%-99.999% |

| Durchmesser: | 0,5-5 Zoll |

| Die Dichte: | 1,95-2,20 g/cm3 |

| Produktionsmethode: | CVD |

Pyrolytisches Bornitrid-Heizgerät

Pyrolytisches Bornitrid-Heizgerät kombiniert drei Schichten aus ultrahochreinem keramik (PBN-PG-PBN), um ein fortschrittliches keramisches Heizelementsystem herzustellen. Pyrolytisches Bornitrid (PBN) dient als isolierendes Substrat, während pyrolytischer Graphit (PG) als leitende Heizschicht dient. Es wird durch chemische Gasphasenabscheidung (CVD) bei hohen Temperaturen hergestellt. Es zeichnet sich durch hervorragende thermische Gleichmäßigkeit, Temperaturwechselbeständigkeit und chemische Stabilität aus. Sie kann in kürzester Zeit Temperaturen von über 1600 ℃ erreichen. Advanced Ceramics Hub kann kundenspezifische Lösungen für Abmessungen, Form, Betriebstemperatur, Stromstärke und Spannung liefern, um die verschiedenen Anforderungen von Industrie und Forschung zu erfüllen.

Pyrolytisches Bornitrid-Heizgerät Spezifikationen

| Durchmesser: | 0,5 -5 Zoll |

| Leistungsabgabe: | 150-3000W |

| Maximale Betriebstemperatur: | PBN: 1700 ℃, PG: 1600 ℃ |

Pyrolytische Bornitrid-Heizung Vorteile

- Eexzellente Hochtemperaturleistung: Es kann stabil über 1600 ℃ arbeiten.

- Hohe Reinheit und Kontaminationsfreiheit: Keine Gasfreisetzung bei hohen Temperaturen.

- Thermische Gleichmäßigkeit: Es ermöglicht eine gleichmäßige Temperaturverteilung und minimiert die durch thermische Gradienten verursachten Prozessschwankungen.

- Temperaturwechselbeständigkeit: Es kann schnelle Erhitzungs- und Abkühlungszyklen ohne Risse oder Schäden überstehen.

- Chemische Stabilität: Es ist chemisch inert gegenüber fast allen Metallen, Flüssigkeiten und Gasen.

- Schnelle Reaktionszeit: Es heizt sich schnell auf.

- Hochgradig anpassbar: Es ermöglicht eine flexible Gestaltung von Formen, Abmessungen und Wärmegradienten, um spezifische Anforderungen zu erfüllen.

Pyrolytisches Bornitrid-Heizgerät Anwendungen

- Herstellung von Halbleitern: PBN/PG-Heizelemente werden beim Glühen von Wafern, bei der Dünnschichtabscheidung und bei Dotierungsprozessen eingesetzt und bieten eine saubere und gleichmäßige Heizumgebung.

- Molekularstrahlepitaxie (MBE): PBN/PG-Heizelemente können unter Ultrahochvakuumbedingungen zum Züchten hochwertiger einkristalliner Schichten, wie z. B. III-V-Verbindungshalbleiter, verwendet werden.

- Dünnschichtabscheidung: PBN/PG-Heizelemente unterstützen physikalische (PVD) und chemische (CVD) Gasphasenabscheidungsprozesse und gewährleisten Materialreinheit und strukturelle Integrität.

- Forschung an supraleitenden Materialien: PBN/PG-Heizungen bieten eine präzise Hochtemperaturregelung für die Herstellung supraleitender Schichten und Bauelemente.

- Metallverdampfung: PBN/PG-Heizungen können Metallquellen in Vakuumverdampfungssystemen für die Beschichtungs- oder Legierungsherstellung erhitzen.

- Hochtemperaturexperimente: PBN/PG-Heizer können in der Forschung eingesetzt werden, um die thermischen Eigenschaften von Materialien zu testen oder chemische Reaktionen bei hohen Temperaturen durchzuführen.

- Herstellung von optoelektronischen Bauelementen: PBN/PG-Heizungen können eine stabile Hochtemperaturumgebung für das Wachstum von Bauteilen wie Lasern und LEDs liefern.

Materialeigenschaften von pyrolytischem Bornitrid

Pyrolytische Bornitrid-Bearbeitung

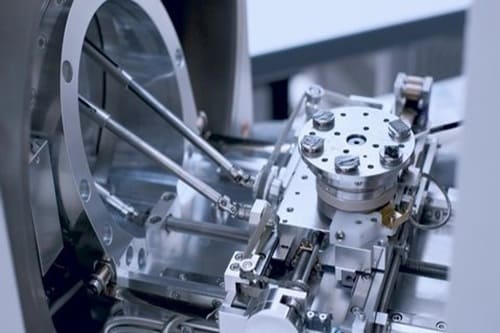

Das Bearbeitungszentrum von Advanced Ceramic Hub ist mit mehreren CNC-Drehbänken und CNC-Fräsmaschinen ausgestattet und verfügt über umfangreiche Erfahrungen in der Bearbeitung. Wir bieten maßgeschneiderte pyrolytische Bornitrid-Keramikprodukte und Profile mit extrem engen Toleranzen, die auf die Kundenanforderungen zugeschnitten sind. Während des Bearbeitungsprozesses sollten die folgenden Vorsichtsmaßnahmen beachtet werden:

- Keramische Werkstoffe aus pyrolytischem Bornitrid können mit normalen Schnellarbeitsstahlwerkzeugen bearbeitet werden. Für härtere und Verbundwerkstoffe werden Hartmetall- oder Diamantwerkzeuge empfohlen.

- Schleifarbeiten können nach Bedarf durchgeführt werden, und für die Bearbeitung von Gewinden können Standardgewindebohrer und Schneideisen verwendet werden.

- Der Bearbeitungsprozess sollte stets trocken erfolgen, ohne dass Schneidöle oder Kühlmittel verwendet werden müssen.

- Schneidewerkzeuge sollten scharf und sauber sein, und Werkzeuge mit negativem Spanwinkel sollten nicht verwendet werden.

- Beim Einspannen und Sichern von Materialien ist darauf zu achten, dass kein übermäßiger Druck ausgeübt wird. Um Kanten- und Eckausbrüche zu vermeiden, sollten Steigfrästechniken verwendet werden.

Verpackungen aus pyrolytischem Bornitrid

Pyrolytische Bornitrid-Keramikprodukte werden in der Regel in vakuumversiegelten Beuteln verpackt, um Feuchtigkeit oder Verunreinigungen zu vermeiden, und mit Schaumstoff umwickelt, um Erschütterungen und Stöße während des Transports zu dämpfen und die Qualität der Produkte in ihrem ursprünglichen Zustand zu gewährleisten.

Herunterladen

Angebot einholen

Wir werden das prüfen und uns innerhalb von 24 Stunden bei Ihnen melden.