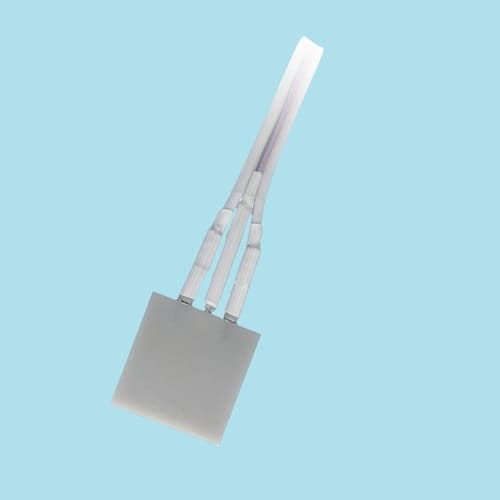

Aluminiumnitrid-Heizung

Aluminiumnitrid-Heizung

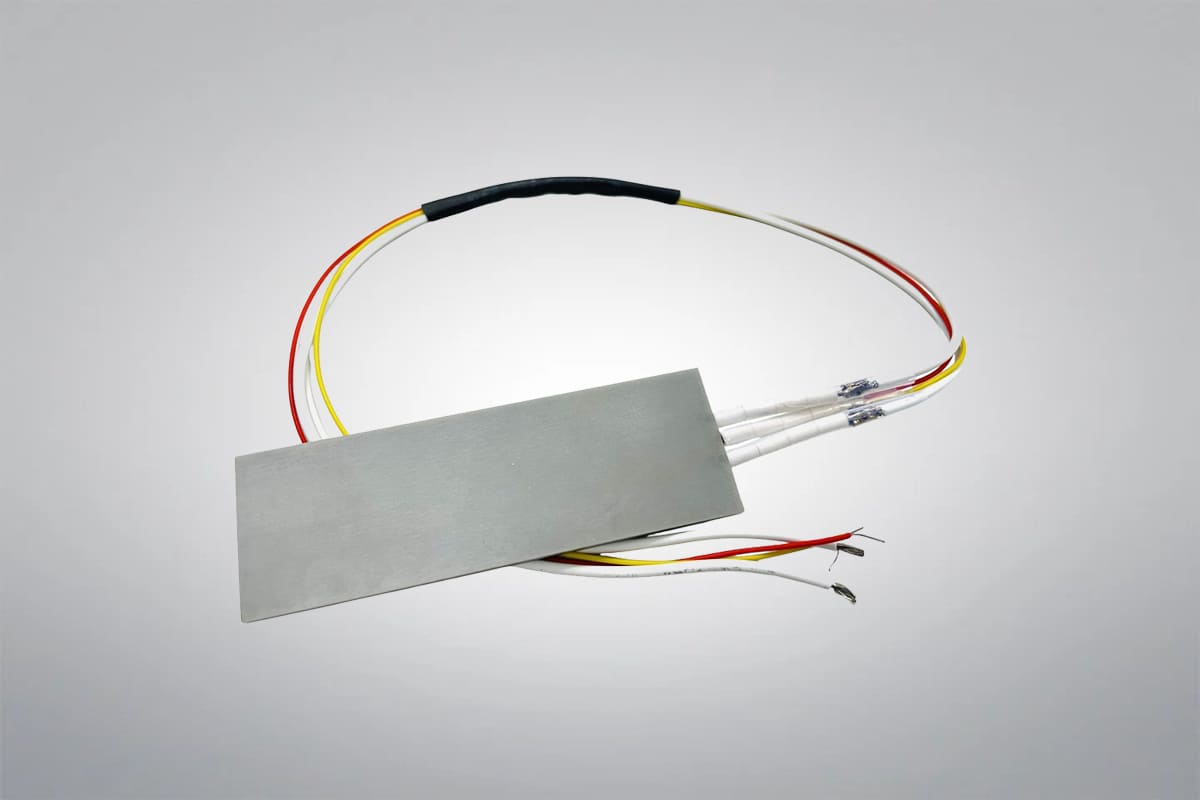

Reinheit: 95%-99%

Die Aluminiumnitrid-Heizung ist ein Hochleistungsheizelement mit außergewöhnlicher Wärmeleitfähigkeit und hoher Temperaturbeständigkeit. Es findet breite Anwendung in der Halbleiterherstellung, der industriellen Wärmebehandlung, bei medizinischen Geräten und in der wissenschaftlichen Forschung. Als führender Anbieter und Hersteller von hochwertigen Aluminiumnitridprodukten können wir hochwertige Aluminiumnitrid-Heizelemente mit verschiedenen Spezifikationen und zu wettbewerbsfähigen Preisen liefern und kundenspezifische Lösungen für spezifische Anforderungen anbieten.

Oder senden Sie uns eine E-Mail an sales@heegermaterials.com.Datenblatt für Aluminiumnitrid-Heizungen

| Referenz-Code: | HM1916 |

| Reinheit: | 95%-99% |

| Die Dichte: | 3,32 g/cm3 |

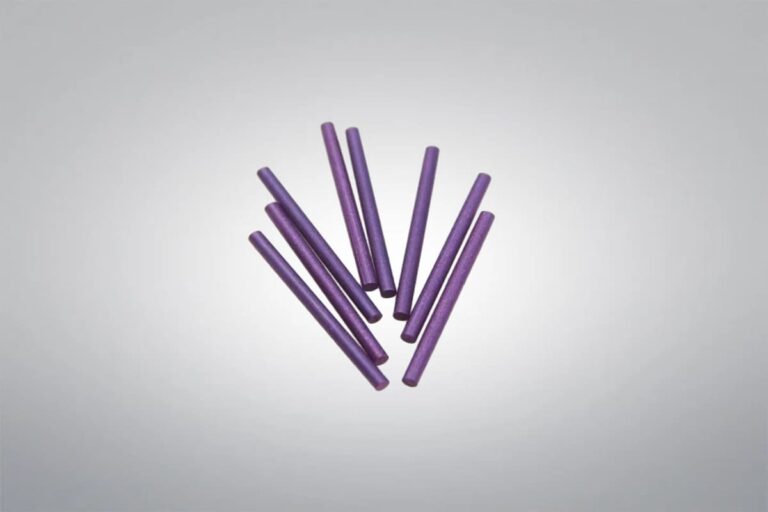

| Erscheinungsbild: | Dunkelgrau / Hellgrau / Beige |

| Die Dicke: | 0,8-3,0 mm |

| Abmessungen: | Kundenspezifisch |

| Maximale Arbeitstemperatur: | 500℃ |

| Maximale Watt-Dichte: | 155 W/cm2 |

| Toleranz des Heizleitungswiderstandes: | ±20% |

| Heizgeschwindigkeit: | 150℃/s |

| TCR: | 0.0015±0.0003 |

Aluminiumnitrid-Heizung

Aluminiumnitrid (AlN)-Kühlkörper werden aus hochreiner Aluminiumnitridkeramik hergestellt. Er liefert eine schnelle, gleichmäßige Erwärmung unter extremen Bedingungen (über 2000℃) und bietet gleichzeitig eine hervorragende Temperaturwechselbeständigkeit und elektrische Isolierung. Er ist ideal für Anwendungen, die eine schnelle Reaktion oder hohe gleichmäßige Temperaturen erfordern. Fortgeschrittene Keramik Hub Wir bieten Massenformung und kundenspezifische Einzelstückoptionen an, um die verschiedensten Anforderungen von Industrie und Forschung zu erfüllen, mit flexibler und schneller Anpassung von Produktgröße und -umfang.

Vorteile von Aluminiumnitrid-Heizungen

- Kann hohen Temperaturen von bis zu 1000°C standhalten.

- Außergewöhnliche Wärmeleitfähigkeit (170-220 W/m-K) und gleichmäßige Wärmeverteilung.

- Hartes, dichtes, nicht poröses Substrat mit hohem Reinheitsgrad.

- Hervorragende Beständigkeit gegen Feuchtigkeit und Chemikalien.

- Ausgezeichnete Flexibilität bei der Anpassung von Größe und Form.

- Präzise und wiederholbare Musterung mit gleichmäßig verteilter Wattzahl.

- Ausgezeichnete dielektrische Eigenschaften

- Niedriger Wärmeausdehnungskoeffizient

- Geringe Masse: schnelles Anfahren und Abkühlen der Temperatur

- Geringer Ableitstrom

- Keine Ausgasung bei anorganischen Systemen

Aluminiumnitrid-Heizungen Anwendungen

- Herstellung von Halbleitern: Wird in Wafer-Verarbeitungsanlagen und Anlagen zur Dünnschichtabscheidung eingesetzt, um eine gleichmäßige Erwärmung bei hohen Temperaturen zu gewährleisten.

- Industrielle Heizung: Wird in Hochtemperaturöfen oder Wärmebehandlungsanlagen als Heizelement für eine stabile Temperaturregelung verwendet.

- Medizinische Geräte: Anwendung in Geräten, die eine präzise Temperaturregelung erfordern (z. B. Laboranalysegeräte), zur schnellen Erwärmung und Isolierung.

- Elektronikindustrie: Wird bei der Prüfung und Herstellung von elektronischen Bauteilen verwendet und bietet eine effiziente und gleichmäßige Wärmequelle.

- Wissenschaftliche Forschung: Dient als zuverlässiges Heizwerkzeug in der Materialforschung und bei Hochtemperaturexperimenten.

Materialeigenschaften von Aluminiumnitrid

Aluminiumnitrid-Werkstoffklassen

HMAN1000 ist unser Standardmaterial aus hochreinem Aluminiumnitrid mit einer Wärmeleitfähigkeit von 170 W/mK. Es hat die gleiche Wärmeleitfähigkeit wie unser Trägermaterial, bietet aber die Möglichkeit, größere Stücke in Länge/Breite und in Dicken bis zu 30 mm herzustellen.

HMAN1000 hat einen guten Wärmeausdehnungskoeffizienten, der über weite Temperaturbereiche mit dem von Silizium und Galliumnitrid vergleichbar ist.

HMAN100 Anwendungen:

- Hochleistungs-Isolatoren

- Laser-Komponenten

- Wassergekühlte Kühlkörper

- Leistungselektronik

- Komponenten für Luft- und Raumfahrt, Medizintechnik und Halbleiter

HMAN1000S 170 W/mK ist unser Standard-Substratmaterial mit hoher Wärmeleitfähigkeit. Es sind jedoch auch andere Hochleistungsqualitäten erhältlich.

HMAN1000S Anwendungen:

- Wärmesenken

- Wärmespreizer

- Laser-Kühlkörper Leistungsgleichrichter

- Luft- und Raumfahrt, Leistungselektronik, Gleichrichter

HMAN2000 ist eine unserer verbesserten Aluminiumnitridqualitäten, die alle mechanischen Eigenschaften von HMAN1000 mit dem zusätzlichen Vorteil einer Wärmeleitfähigkeit von 200 W/mK bietet.

HMAN2000-Anwendungen:

- Wärmesenken

- Wärmespreizer

- Laser-Kühlkörper Leistungsgleichrichter

- Luft- und Raumfahrt, Leistungselektronik, Gleichrichter

HMAN3000 ist eine unserer verbesserten Aluminiumnitridqualitäten, die alle mechanischen Eigenschaften von HMAN1000 mit dem zusätzlichen Vorteil einer Wärmeleitfähigkeit von 230 W/mK bietet.

HMAN3000 Anwendungen:

- Wärmesenken

- Wärmespreizer

- Laser-Kühlkörper Leistungsgleichrichter

- Luft- und Raumfahrt, Leistungselektronik, Gleichrichter

HMAN4000 ist eine unserer verbesserten Aluminiumnitridqualitäten, die alle mechanischen Eigenschaften von HMAN1000 mit dem zusätzlichen Vorteil einer Wärmeleitfähigkeit von 200 W/mK bietet.

HMAN4000 Anwendungen:

- Wärmesenken

- Wärmespreizer

- Laser-Kühlkörper Leistungsgleichrichter

- Luft- und Raumfahrt, Leistungselektronik, Gleichrichter

Aluminiumnitrid-Keramik-Bearbeitung

Die Keramikbearbeitung von Aluminiumnitrid (AlN) ist ein präzises Verfahren zur Herstellung von Hochleistungskomponenten aus Aluminiumnitridwerkstoffen. Die Bearbeitung von Aluminiumnitridkeramik erfordert spezielle Geräte und Techniken, um die Sprödigkeit und Härte des Materials zu bewältigen. Geeignete Werkzeuge und kontrollierte Umgebungen sind unerlässlich, um Materialschäden zu vermeiden und die gewünschte Oberflächengüte und Maßgenauigkeit zu erreichen. Die üblichen Bearbeitungsmethoden sind folgende:

- Diamantschneiden: Diamantwerkzeuge werden zur Erzielung feiner Präzision und glatter Oberflächen verwendet und sind ideal für komplexe Formen.

- Laserschneiden: Ein berührungsloses Verfahren für komplizierte Formen, mit hoher Präzision und minimaler thermischer Belastung.

- Präzisionsschleifen: Wird verwendet, um feine Toleranzen und Oberflächengüten zu erzielen. Erfordert besondere Sorgfalt, um Risse oder Abplatzungen aufgrund der Sprödigkeit der Keramik zu vermeiden.

- Drahterodieren (Electrical Discharge Machining): Ein Verfahren, das häufig für komplizierte Schnitte verwendet wird, insbesondere für dünne und komplexe Geometrien.

Aluminiumnitrid-Keramik-Verpackungen

Aluminiumnitrid-Keramikprodukte werden in der Regel in vakuumversiegelten Beuteln verpackt, um Feuchtigkeit oder Verunreinigungen zu vermeiden, und mit Schaumstoff umwickelt, um Erschütterungen und Stöße während des Transports abzufedern und die Qualität der Produkte im Originalzustand zu gewährleisten.

Herunterladen

Angebot einholen

Wir werden das prüfen und uns innerhalb von 24 Stunden bei Ihnen melden.