Aluminiumnitrid-Granulat-Pulver

Aluminiumnitrid-Granulat-Pulver

Reinheit: 99%-99.9%

Partikelgröße: 30-120 μm, oder kundenspezifisch

Aluminiumnitrid-Granulat ist ein keramischer Hochleistungswerkstoff, der sich durch seine hervorragende Formbarkeit und Fließfähigkeit auszeichnet. Es eignet sich für Verfahren wie Trockenpressen, halbtrockenes Pressen und kaltes isostatisches Pressen. Als führender Anbieter und Hersteller von hochwertigen Aluminiumnitridprodukten können wir hochwertige Aluminiumnitrid-Granulierpulver mit verschiedenen Spezifikationen und zu wettbewerbsfähigen Preisen liefern und kundenspezifische Lösungen für spezifische Anforderungen anbieten.

Oder senden Sie uns eine E-Mail an sales@heegermaterials.com.Datenblatt Aluminiumnitrid-Granulat-Pulver

| Referenz-Code: | HM1912 |

| Reinheit: | 99%-99.9% |

| Partikelgröße: | 30-120 μm oder kundenspezifisch |

| CAS: | 24304-00-5 |

| Schmelzpunkt: | 2200℃ |

| Siedepunkt: | 2249℃ |

Aluminiumnitrid-Granulat-Pulver

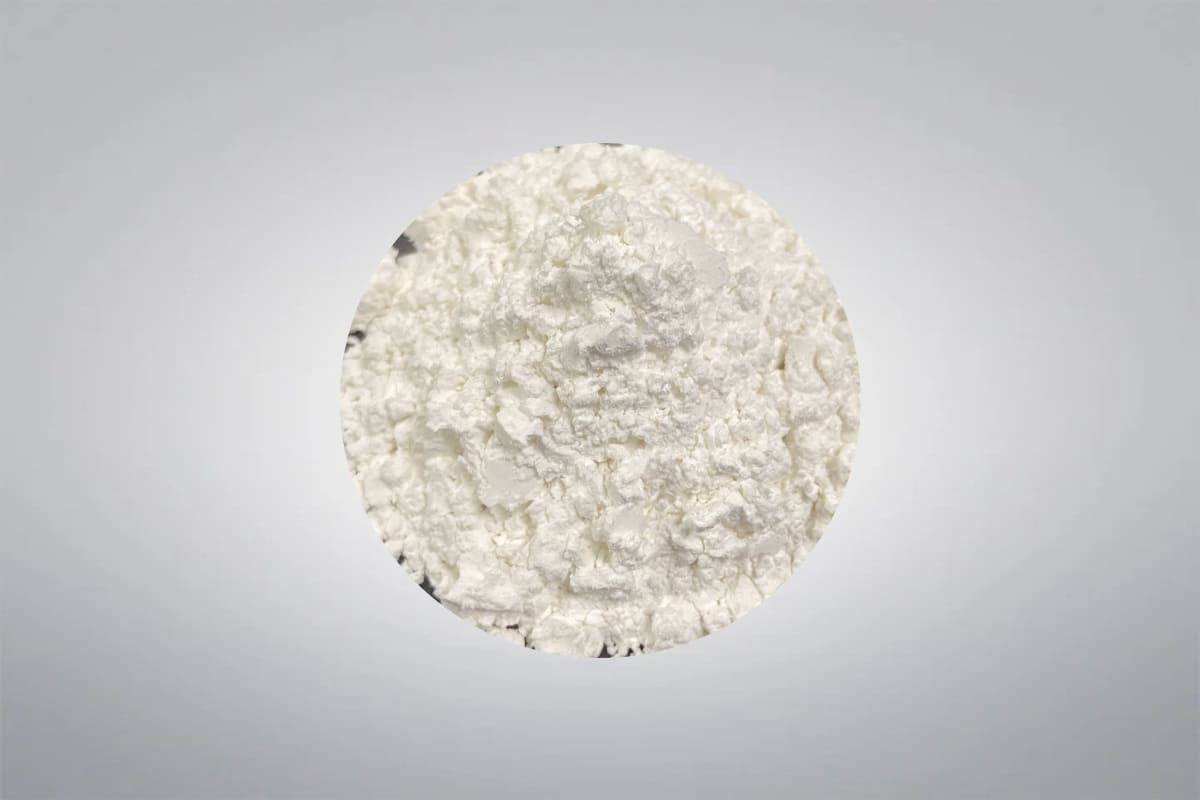

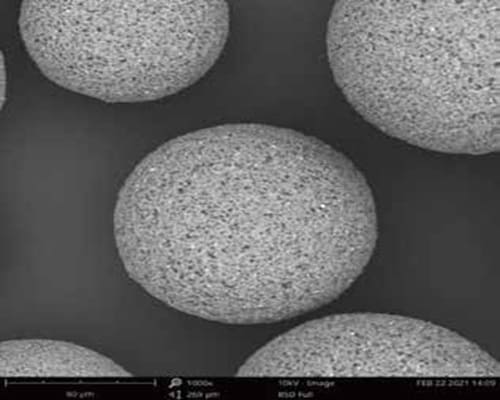

Aluminiumnitrid-Granulatpulver wird durch Sprühgranulation im Mikronbereich hergestellt und enthält Bindemittel und Sinterhilfsmittel. Es hat eine gute Fließfähigkeit und gewährleistet eine vollständige Formfüllung. Der gepresste Körper weist keine Defekte auf und hat eine gleichmäßige und konsistente Dichte. Es ist in erster Linie für Trockenpressen, halbtrockenes Pressen und kaltes isostatisches Pressen geeignet. Fortgeschrittene Keramik Hub kann maßgeschneiderte Lösungen in Bezug auf Reinheit und Partikelgröße für verschiedene Anwendungen in Industrie und Forschung anbieten.

Spezifikationen für Aluminiumnitrid-Granulat-Pulver

| Produkt | AlN-Granulat-Pulver-1 | AlN-Granulat-Pulver-2 | |

| Durchschnittliche Partikelgröße (μm)) | 40-60 | 8-15 | |

| Sphärizität | 40-60% | ≥98% | |

| Y2O3 (wt%) | 3-4 | 4-5 | |

| Gehalt an Verunreinigungen | Ca (ppm) | <30 | <50 |

| Fe (ppm) | <15 | <20 | |

| Si (ppm) | <40 | <50 | |

| Scheinbare Dichte (g/cm)3) | 0.8-1.0 | 0.8-1.0 | |

| Halle Durchflussrate (s/50g) | 80-100 | 80-100 | |

| Empfohlene Sintertemperatur | 1750-1850 ℃ | ||

| Hinweis | Sinterhilfsmittel können je nach Kundenwunsch formuliert werden. | ||

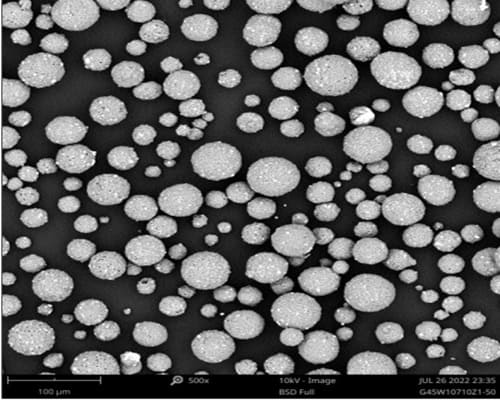

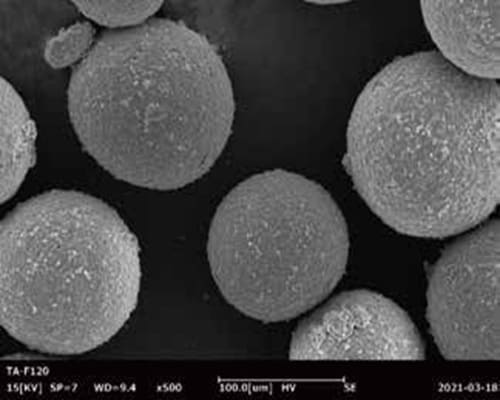

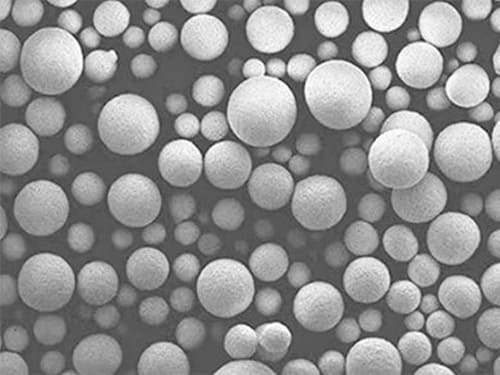

Morphologie von Aluminiumnitrid-Granulat-Pulver

Aluminiumnitrid-Granulierpulver Merkmale

- Gute Sphärizität

- Hohe Sinteraktivität

- Ausgezeichnete Fließfähigkeit

- Hohe Festigkeit

Aluminiumnitrid-Pulver-Lösungen

Granulat Pulver

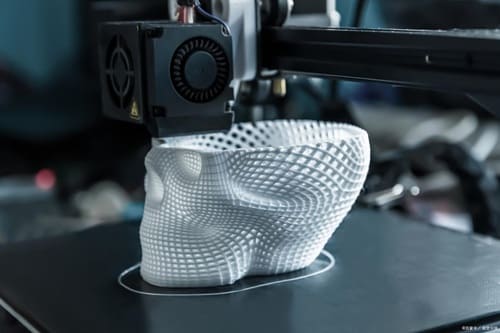

Aluminiumnitrid-Granulatpulver mit hervorragender Formbarkeit und Fließfähigkeit ist ideal für das Trockenpressen, halbtrockenes Pressen und kaltes isostatisches Pressen, das in elektrostatischen Spannvorrichtungen und keramischen Komponenten verwendet wird.

Aluminiumnitrid Granulationspulver Anwendungen

- Elektronik- und Halbleiterindustrie

- Herstellung von Keramiken

- Fortschrittliche Sinterverfahren

- LED & Optoelektronik

- Luft- und Raumfahrt und Automobilanwendungen

Aluminiumnitrid-Granulat-Pulver-Verpackung

Das Aluminiumnitrid-Granulatpulver wird sorgfältig in Holzkisten oder Kartons verpackt, die zusätzlich mit weichen Materialien gestützt werden, um ein Verrutschen während des Transports zu verhindern. Diese Verpackungsmethode garantiert die Unversehrtheit der Produkte während des gesamten Lieferprozesses.

Herunterladen

Angebot einholen

Wir werden das prüfen und uns innerhalb von 24 Stunden bei Ihnen melden.