Tonerde-Pulver

Tonerde-Pulver

Reinheit: 99,9%-99,999%

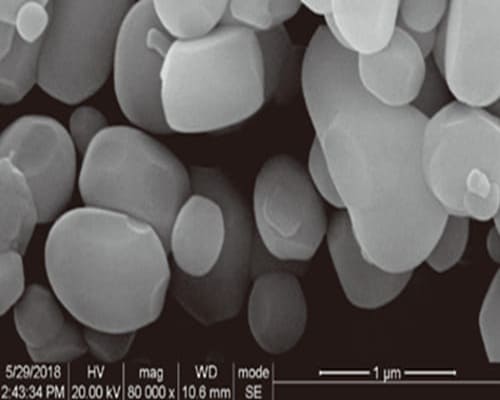

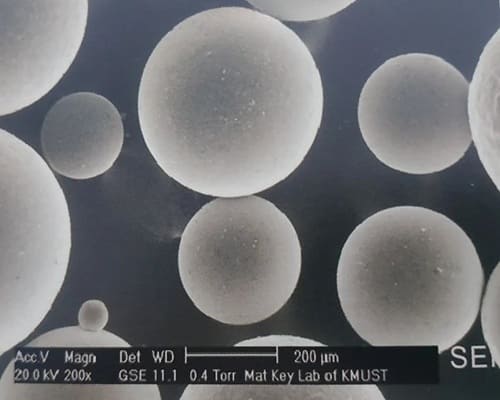

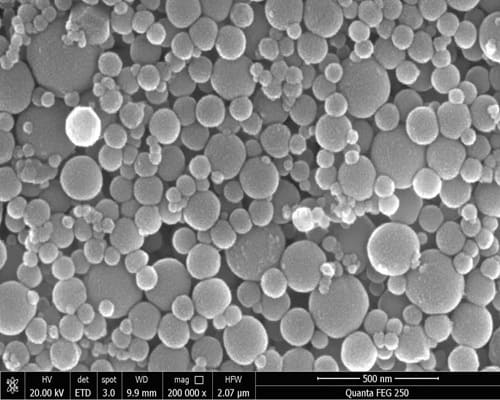

Morphologie: Fast kugelförmig, kugelförmig oder unregelmäßig

Aluminiumoxidpulver wird hauptsächlich aus hochreinem Aluminiumoxid (Al2O3) hergestellt und zeichnet sich durch hohe Hitzebeständigkeit, gute Formbarkeit, stabile Kristallphase, hohe Härte und ausgezeichnete Dimensionsstabilität aus. Als führender Anbieter und Hersteller von hochwertigen Aluminiumoxidprodukten können wir hochwertige Aluminiumoxidpulver mit verschiedenen Spezifikationen und zu wettbewerbsfähigen Preisen liefern und kundenspezifische Lösungen für spezifische Anforderungen anbieten.

Oder senden Sie uns eine E-Mail an sales@heegermaterials.com.Datenblatt Aluminiumoxid-Pulver

| Referenz-Code: | HM1970 |

| Reinheit: | 99.9%-99.999% |

| Morphologie: | Fast kugelförmig, kugelförmig oder unregelmäßig |

| Erscheinung: | Weißes Puder |

| Partikelgröße: | Submikron bis 500 Mikron oder im Nanomaßstab |

Tonerde-Pulver

Tonerdepulver ist ein weißes Pulver mit einer Reinheit von 99,9% bis 99,999%. Hochreine Aluminiumoxidpulver sind ideal für die Züchtung von Saphiren, Lithium-Ionen-Batterien, LED-Substraten, Spezialitäten keramikund industrielle Katalysatoren. Sie können auch zum Polieren, Wärmemanagement und für Katalysatoren verwendet werden. Je nach den spezifischen Anwendungsanforderungen können die Partikelgröße, die Reinheit und die Morphologie angepasst werden. Advanced Ceramics Hub kann qualitativ hochwertiges Aluminiumoxid (Al2O3)-Pulver in Form von nahezu kugelförmigen, kugelförmigen, unregelmäßigen und nanoskaligen Partikeln liefern, um verschiedene Anforderungen der Industrie und Forschung zu erfüllen.

Aluminiumoxidpulver Feinteilige Lösungen

Aluminiumoxid-Pulver Merkmale

- Hohe Reinheit: Bietet hochreine Aluminiumoxidpartikel, die Stabilität und Leistung in Anwendungen gewährleisten.

- Ausgezeichnete thermische Stabilität: Behält stabile physikalische und chemische Eigenschaften in Hochtemperaturumgebungen bei.

- Gute Fließfähigkeit: Das granulierte Aluminiumoxid-Pulver weist eine ausgezeichnete Fließfähigkeit auf, die eine automatisierte Produktion und präzise Dosierung erleichtert.

- Hohe Härte und Abriebfestigkeit: Weist eine hohe Härte und eine ausgezeichnete Verschleißfestigkeit auf und eignet sich daher für Anwendungen, die eine hohe Verschleißfestigkeit erfordern.

Aluminiumoxid-Pulver Anwendungen

- Keramische Herstellung: Herstellung von hochfesten Keramiken und Substraten.

- Abrasives Polieren: Wird als Schleifmittel für die Oberflächenbehandlung von Metallen und Glas verwendet.

- Feuerfeste Materialien: Formt Hochtemperatur-Ofenauskleidungen und Isolierungen.

- Elektronik: Herstellung von Isolierschichten und Schaltkreissubstratmaterialien.

- Katalysator-Unterstützung: Unterstützt katalytische Prozesse bei chemischen Reaktionen.

Aluminiumoxid-Pulver-Verpackungen

Das Tonerdepulver wird sorgfältig in Holzkisten oder Kartons verpackt, die zusätzlich mit weichen Materialien gestützt werden, um ein Verrutschen während des Transports zu verhindern. Diese Verpackungsmethode garantiert die Unversehrtheit der Produkte während des gesamten Lieferprozesses.

Herunterladen

Angebot einholen

Wir werden das prüfen und uns innerhalb von 24 Stunden bei Ihnen melden.