Sapphire Rod

Sapphire Rod

Sapphire Rod is a high-purity single-crystal cylindrical material used for further processing in optical, electronic, and industrial applications. Grown with stable crystal orientation—often exposing the C-plane (0001) widely used in LED production—it offers strong mechanical strength, chemical stability, and durability under high temperatures. Available in diameters from 2 to 8 inches and customizable orientations and dimensions, Sapphire Rod provides a reliable base material for precision components, substrates, and advanced engineering needs. We can supply high-quality Sapphire Rods with various specifications and competitive prices, offering customized solutions to meet specific requirements.

Oder senden Sie uns eine E-Mail an sales@heegermaterials.com.Sapphire Rod Data Sheet

| Dichte | 3.97–4.1 g/cm3 |

| Materialien | AI2O3 |

| Schmelzpunkt | 2045 ℃ |

Sapphire Rod Description

Sapphire Rod is produced as a uniform single-crystal cylinder with excellent hardness, optical stability, and resistance to chemical corrosion. Its consistent structure makes it suitable for slicing, polishing, and machining into precision parts such as optical substrates, mechanical components, and electronic devices. With customizable crystal orientations and a wide range of size options, it supports applications requiring strong durability and high thermal tolerance.

Sapphire Rod Specifications

| Artikel | Spezifikation |

|---|---|

| Crystal Materials | 99.999% High-Purity Monocrystalline Al₂O₃ |

| Orientation | C-plane (0001), A-plane (11-20), M-plane (10-10), R-plane (1-102), N-plane (11-23), V-plane (22-43) |

| Durchmesser | 2-inch, 4-inch, 6-inch, 8-inch, etc. |

| Flat | Upon request |

| Oberfläche | Fine Ground |

| Packaging | Single-piece packaging |

Sapphire Infrared Transmittance at Different Thicknesses

Sapphire Rod Key Features

- High Crystal Purity: Made from high-purity monocrystalline Al₂O₃ with stable crystal orientation for reliable performance.

- Ausgezeichnete mechanische Festigkeit: Features high hardness and durability, suitable for slicing, grinding, and precision machining.

- Thermal and Chemical Stability: Maintains performance under high temperatures and is resistant to most acids and alkalis.

- Multiple Crystal Orientations Available: Includes C-plane, A-plane, M-plane, R-plane, N-plane, and V-plane to meet different processing needs.

- Anpassbar Abmessungen: Offered in various diameters from 2 to 8 inches with options for custom size, flat, and surface finish.

Sapphire Rod Applications

- LED Substrates: Used to produce C-plane sapphire wafers widely applied in LED manufacturing.

- Optical Components: Serves as raw material for lenses, windows, prisms, and other precision optical parts.

- Elektronische Geräte: Applied in laser components, insulating parts, and high-temperature semiconductor applications.

- Industrielle Maschinen: Used to fabricate wear-resistant and corrosion-resistant parts such as shafts, pins, and guides.

- Scientific Research: Supports crystal growth studies, experimental setups, and advanced material development requiring high-purity single-crystal structures.

Sapphire Material Properties

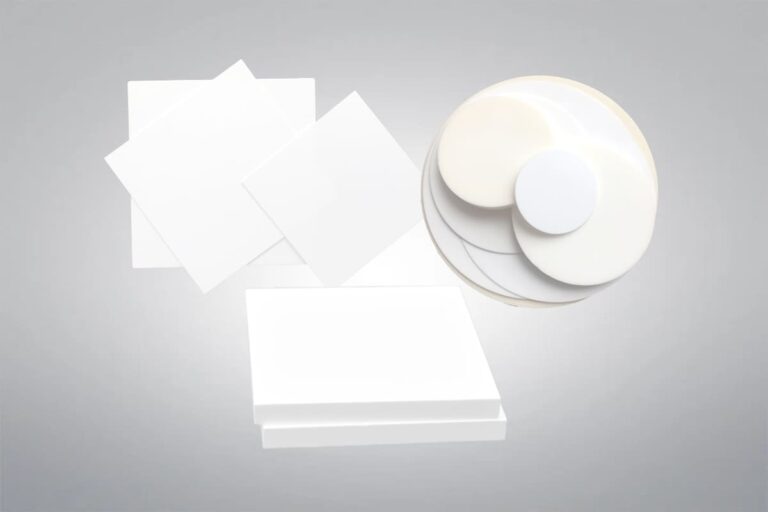

Sapphire Products Packaging

Sapphire Products are typically packaged in vacuum-sealed bags to prevent moisture or contamination and wrapped with foam to cushion vibrations and impacts during transport, ensuring the quality of products in their original condition.

Herunterladen

Angebot einholen

Wir werden das prüfen und uns innerhalb von 24 Stunden bei Ihnen melden.