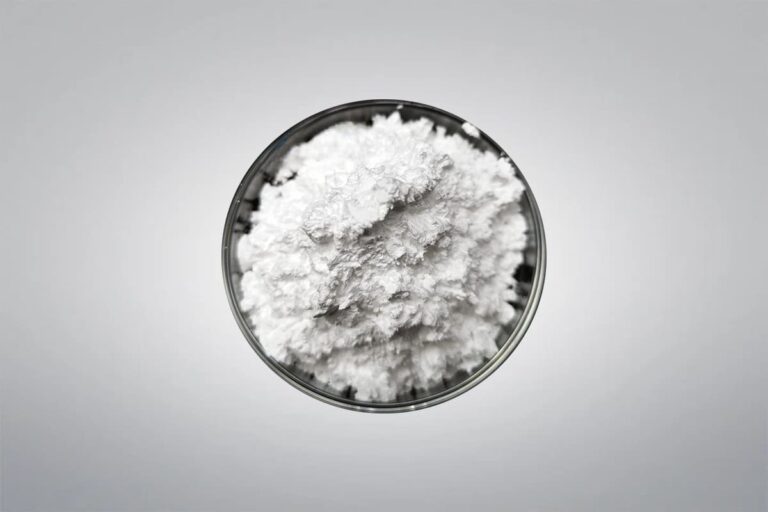

Plaque/feuille/disque PZT

Plaque/feuille/disque PZT

Plaque/feuille/disque PZT offre des performances piézoélectriques exceptionnelles avec une sensibilité élevée, un couplage électromécanique fort et une stabilité fiable, ce qui le rend bien adapté aux applications dans les capteurs, les actionneurs, les transducteurs à ultrasons et les systèmes de positionnement de précision. Avec une excellente réponse en fréquence et une grande durabilité, il garantit des performances constantes dans des environnements industriels et de recherche exigeants. Nous pouvons fournir des plaques, des feuilles et des disques de PZT de haute qualité. avec des spécifications variées et des prix compétitifs, offrant des solutions personnalisées pour répondre à des exigences spécifiques.

Ou envoyez-nous un courriel à l'adresse suivante sales@heegermaterials.com.Fiche technique des plaques/feuilles/disques PZT

| Couleur : | Blanc |

| Matériau : | Titanate de zirconate de plomb (PZT) |

| Forme : | Plaque / Tôle / Disque |

| Dimension : | Standard ou personnalisé |

Description des plaques/feuilles/disques PZT

Les plaques, feuilles et disques PZT sont des produits céramiques piézoélectriques de haute performance connus pour leur fort couplage électromécanique, leur constante diélectrique élevée et leurs caractéristiques de fréquence stables. Il est largement utilisé dans les capteurs, les actionneurs, les dispositifs à ultrasons et les systèmes de mouvement de précision où la rapidité de réponse et la fiabilité sont essentielles. Grâce à son excellente résistance mécanique et à ses performances constantes dans toute une série de conditions de fonctionnement, il garantit une longue durée de vie et une fonctionnalité précise dans des environnements industriels et de recherche exigeants.

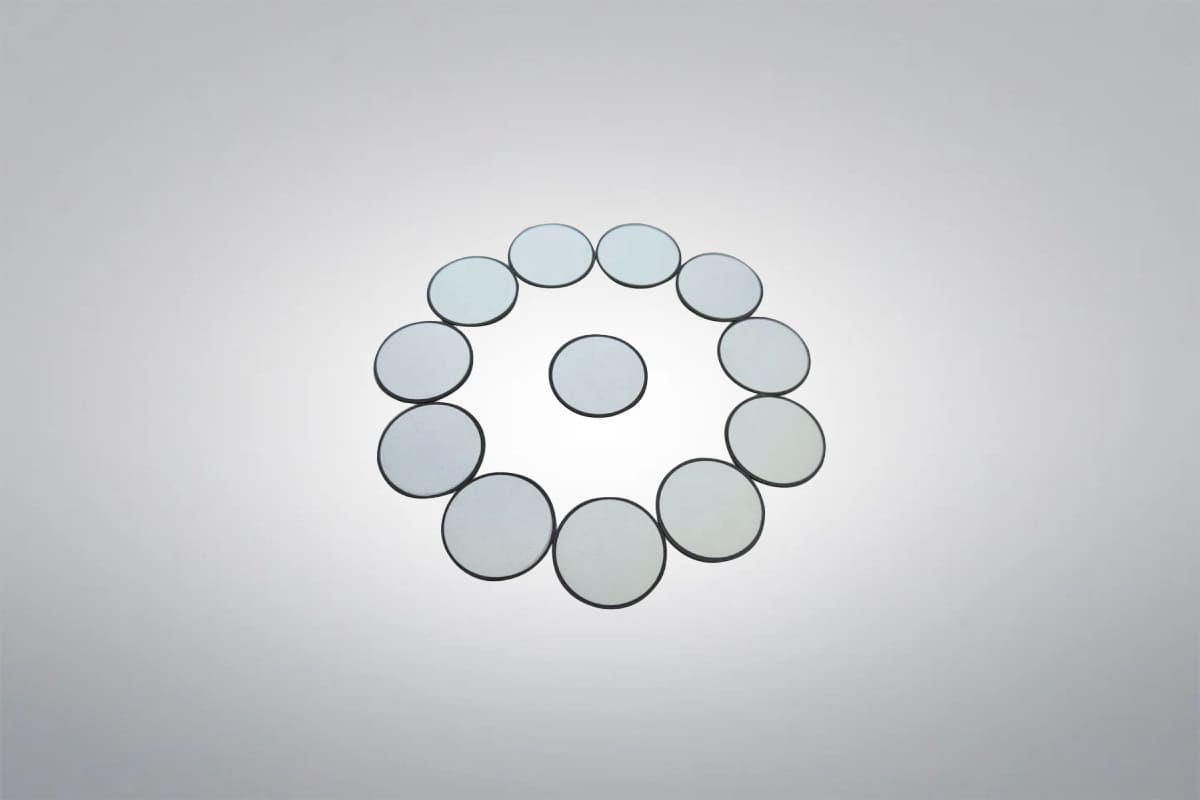

Plaque PZT Feuille PZT Disque PZT

Plaque carrée en PZT Spécifications techniques

| Modèle | Longueur L [mm] ±0,1 | Largeur W [mm] ±0,1 | Hauteur [mm] ±0,05 | Poids [g] ±5% | Tension d'entraînement [V] | Déplacement [μm] ±15% | Capacité [nF] ±15% | Fréquence de résonance [kHz] ±20% | Rigidité [N/μm] ±20% | Force [N] ±20% |

|---|---|---|---|---|---|---|---|---|---|---|

| NAC2001 | 2 | 2 | 2 | 0.07 | 60 | 3 | 150 | >486 | 56 | 168 |

| CNA2002 | 3 | 3 | 2 | 0.15 | 60 | 3 | 400 | >486 | 126 | 378 |

| CNA2003 | 5 | 5 | 2 | 0.37 | 60 | 3 | 1080 | >486 | 350 | 1050 |

| CNA2011 | 2 | 2 | 2 | 0.05 | 150 | 3.3 | 25 | >486 | 51 | 168 |

| CNA2012 | 3 | 3 | 2 | 0.14 | 150 | 3.3 | 65 | >486 | 115 | 378 |

| CNA2013 | 5 | 5 | 2 | 0.40 | 150 | 3.3 | 190 | >486 | 318 | 1050 |

| CNA2014 [1] | 7 | 7 | 2 | 0.79 | 150 | 3.3 | 380 | >486 | 624 | 2060 |

| CNA2015 [2] | 10 | 10 | 2 | 1.58 | 150 | 3.3 | 760 | >486 | 1273 | 4200 |

| NAC2021 [1] | 7 | 7 | 2 | 0.78 | 200 | 3.3 | 220 | >486 | 624 | 2060 |

| NAC2022 [2] | 10 | 10 | 2 | 1.61 | 200 | 3.3 | 440 | >486 | 1273 | 4200 |

| NAC2023 [3] | 15 | 15 | 2 | 3.66 | 200 | 3.3 | 970 | >486 | 2864 | 9450 |

| CNA2017 | 20 | 20 | 2 | 6.40 | 200 | 3.3 | 1800 | >486 | 5091 | 16800 |

| NAC2024 | 3 | 3 | 2 | 0.14 | 200 | 1.9 | 25 | >500 | 161 | 290 |

| NAC2025 | 5 | 5 | 2 | 0.38 | 200 | 1.9 | 80 | >500 | 400 | 800 |

| 012605 Electrode en or | 3 | 3 | 1 | 0.09 | 200 | 1.5 | 25 | – | 210 | 360 |

Notes :

- A faible amplitude (quelques volts), la fréquence de fonctionnement peut atteindre des dizaines de kHz.

- Température maximale de fonctionnement : 200°C. Utiliser des méthodes de soudure à haute température.

- [1] Tolérance en longueur et en largeur ±0,15 mm

- [2] Tolérance en longueur et en largeur ±0,2 mm

- [3] Tolérance en longueur et en largeur ±0,3 mm

Caractéristiques des plaques, feuilles et disques PZT

- Haute performance piézoélectrique : Fournit un couplage électromécanique puissant, ce qui le rend idéal pour les capteurs, les actionneurs et les transducteurs à ultrasons.

- Personnalisable Dimensions : Disponibles en différentes tailles, formes et épaisseurs pour répondre aux différents besoins de l'industrie et de la recherche.

- Propriétés stables du matériau : Maintient des performances diélectriques, mécaniques et thermiques constantes sur une large plage de températures.

- Adaptation à une large gamme de fréquences : Il permet de fonctionner aussi bien dans les applications à basse qu'à haute fréquence, ce qui garantit une grande souplesse de conception.

- Durable et fiable : Offre une longue durée de vie avec une résistance à l'usure mécanique et à la dégradation de l'environnement.

Applications des plaques, feuilles et disques PZT

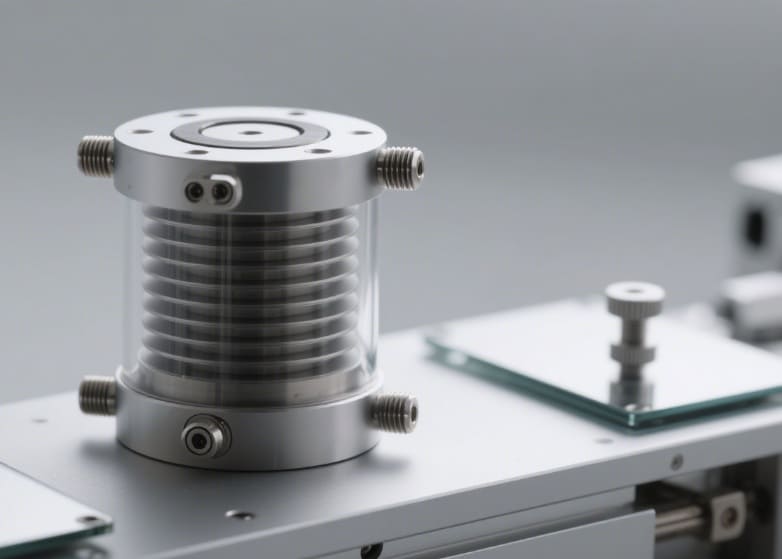

- Transducteurs à ultrasons : Utilisé dans l'imagerie médicale, la détection des défauts et les systèmes de sonar sous-marin.

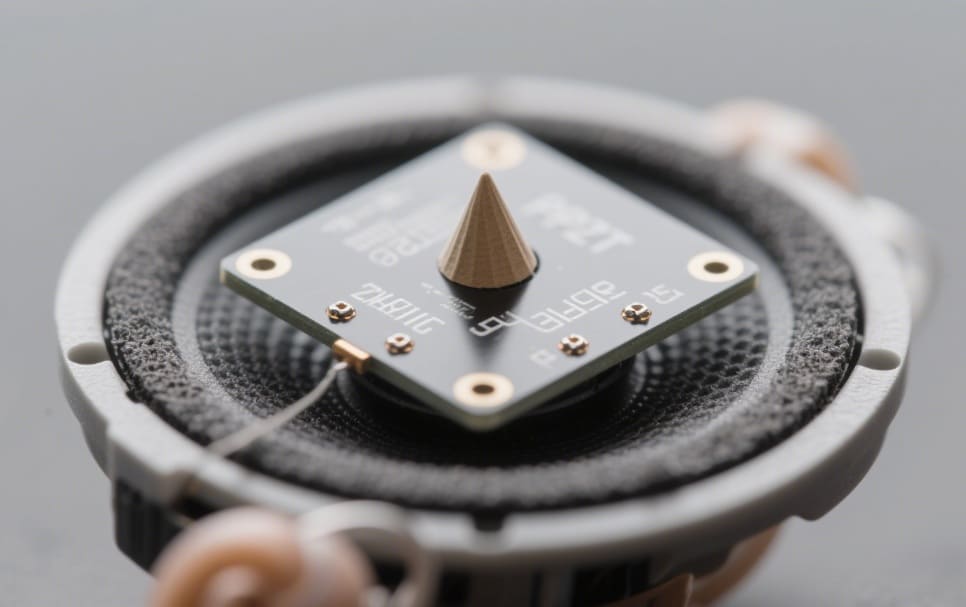

- Capteurs de précision : Utilisé dans les dispositifs de détection de pression, d'accélération et de vibration.

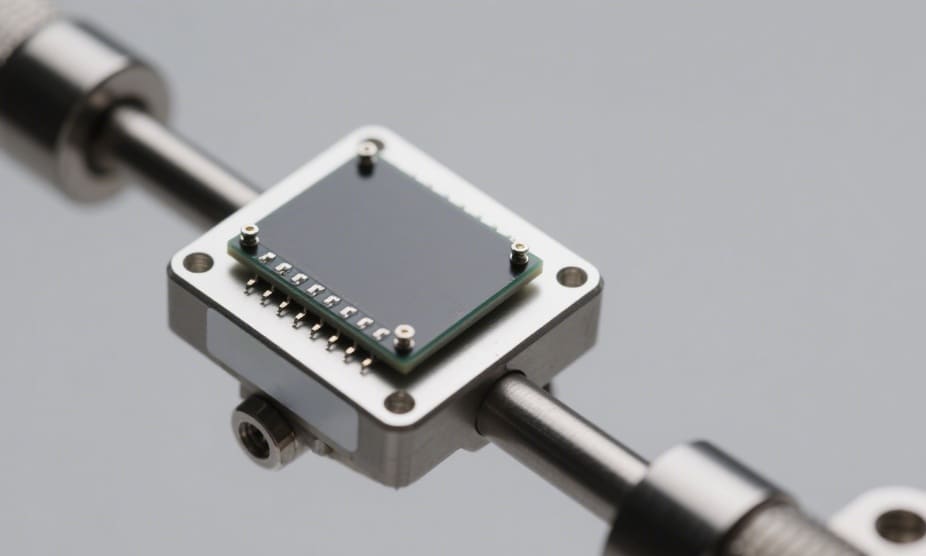

- Actionneurs : Intégré dans les systèmes de positionnement de précision, les micro-pompes et l'optique adaptative.

- Dispositifs de récolte d'énergie : Convertir les vibrations mécaniques en énergie électrique pour l'électronique de faible puissance.

- Dispositifs acoustiques : Utilisé dans les haut-parleurs, les buzzers et les équipements de production d'ondes sonores.

Propriétés des matériaux céramiques PZT

| Propriétés | Matériaux | |||||||||||

| PZT4 | PZT5 | PZT8 | ||||||||||

| 840 | 841 | 842** | 844** | 850 | 851** | 854 | 855 | 860 | 880 | 881** | ||

| Permittivité relative | KT | 1275 | 1375 | 1375 | 1500 | 1900 | 1950 | 2750 | 3300 | 1200 | 1050 | 1030 |

| Facteur de perte diélectrique (%) | tan δ | 0.60 | 0.40 | 0.45 | 0.40 | ≤ 2.00 | 1.50 | ≤ 2.00 | ≤ 2.50 | ≤2.00 | 0.40 | 0.40 |

| Température de Curie (°C) | Tc | 325 | 320 | 325 | 320 | 360 | 360 | 250 | 200 | 360 | 310 | 310 |

| Coefficient de couplage électromécanique | kp | 0.59 | 0.60 | 0.65 | 0.68 | 0.63 | 0.71 | 0.66 | 0.68 | 0.50 | 0.50 | 0.58 |

| k33 | 0.72 | 0.68 | – | – | 0.72 | – | 0.68 | 0.76 | 0.45 | 0.62 | – | |

| k31 | 0.35 | 0.33 | – | – | 0.36 | – | – | 0.40 | – | 0.30 | – | |

| k15 | 0.70 | 0.67 | – | – | 0.68 | – | – | 0.66 | – | 0.55 | – | |

| kt | – | – | 0.48 | 0.48 | – | 0.51 | – | – | – | – | 0.46 | |

| Constante de charge piézoélectrique (10-¹² C/N ou 10-¹² m/V) | d33 | 290 | 300 | 300 | 300 | 400 | 400 | 600 | 630 | 380 | 215 | 220 |

| -d31 | 125 | 109 | – | – | 175 | – | 260 | 276 | – | 95 | – | |

| d15 | 480 | 450 | – | – | 590 | – | 625 | 720 | – | 330 | – | |

| Constante de tension piézoélectrique (10-³ Vm/N ou 10-³ m²/C) | g33 | 26.5 | 25.5 | 26.3 | 24.5 | 24.8 | 24.8 | 25.5 | 21.0 | 38.0 | 25.0 | 26.7 |

| -g31 | 11.0 | 10.5 | – | – | 12.4 | – | – | 9.0 | – | 10.0 | – | |

| g15 | 38.0 | 35.0 | – | – | 36.0 | – | – | 27.0 | – | 28.0 | – | |

| Module d'Young (10¹⁰ N/m²) | YE11 | 8.0 | 7.6 | 8.0 | 7.6 | 6.3 | 6.3 | 6.0 | 5.9 | – | 9.0 | 9.0 |

| YE33 | 6.8 | 6.3 | 6.8 | 6.3 | 5.4 | 5.4 | 5.2 | 5.1 | – | 7.2 | 7.2 | |

| Constante de fréquence (Hz-m ou m/s) | NL (Longueur Direction) | 1524 | 1700 | – | – | 1500 | – | – | 1390 | – | 1725 | – |

| NT (Direction de l'épaisseur) | 2005 | 2005 | 2050 | 2050 | 2040 | 2040 | 2000 | 2079 | 1390 | 2110 | 2050 | |

| NP (Direction planaire) | 2130 | 2055 | 2230 | 2250 | 1980 | 2080 | 1972 | 1920 | 1900 | 2120 | 2300 | |

| Densité (g/cm³) | ρ | 7.6 | 7.6 | 7.6 | 7.7 | 7.6 | 7.6 | 7.6 | 7.6 | 6.6 | 7.6 | 7.6 |

| Facteur de qualité mécanique | Qm | 500 | 1400 | 600 | 1500 | 80 | 80 | 70 | 65 | 50 | 1000 | 1000 |

| Impédance acoustique (Mrayl) | – | – | – | – | 31.5 | – | – | – | 16.5 | – | – | |

Notes :

- @ 1 kHz, faible champ électrique

- Les matériaux 842, 844, 851 et 881 sont des produits en stock fournis à titre de référence uniquement et ne sont pas disponibles pour la personnalisation.

Tolérances des céramiques PZT

PZT Propriété du matériau Tolérances des paramètres :

| Paramètres | Tolérance standard | Tolérance plus stricte disponible en option |

|---|---|---|

| Capacités | ±20% | Oui |

| d33 (coefficient piézo) | ±20% | Oui |

| Fréquence | ±5% | ±0,5% |

Tolérances dimensionnelles :

| Forme et dimension | Plage de valeurs standard | Tolérance (±) |

| Disque / Anneau / Tube | ||

| Diamètre extérieur | < 25 mm | 0,25 mm |

| ≥ 25 mm à < 38 mm | 0,38 mm | |

| ≥ 38 mm à < 50 mm | 0,60 mm | |

| ≥ 50 mm | 1,00 mm | |

| Anneau / Tube | ||

| Diamètre intérieur | < 6 mm | 0,25 mm |

| ≥ 6 mm à < 13 mm | 0,38 mm | |

| ≥ 13 mm à < 25 mm | 0,50 mm | |

| ≥ 25 mm | 0,60 mm | |

| Plaque carrée | ||

| Longueur ou largeur | < 13 mm | 0,13 mm |

| ≥ 13 mm à < 25 mm | 0,25 mm | |

| ≥ 25 mm à 38 mm | 0,38 mm | |

| ≥ 38 mm à < 50 mm | 0,60 mm | |

| ≥ 50 mm | 1,00 mm | |

| Épaisseur | 0,20 mm à < 5,00 mm | 0,025 mm |

| ≥ 5,00 mm | 0,05 mm | |

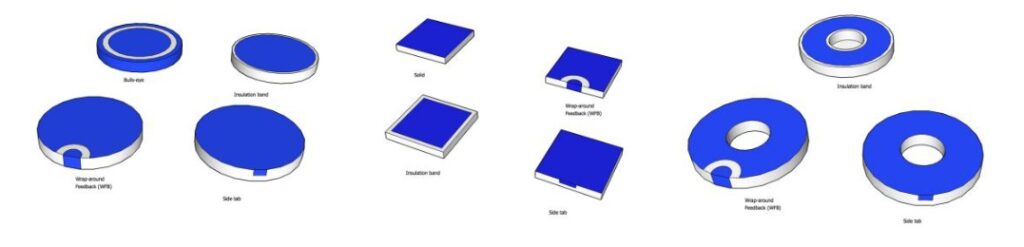

Spécifications des électrodes PZT

- Matériau de l'électrode standard : Argent

- Matériaux d'électrode en option : Or, Nickel

- Configuration standard des électrodes : Électrodes solides couvrant la totalité des surfaces supérieure et inférieure

- Configuration de l'électrode tubulaire : Electrodes sur les parois internes et externes (paroi interne : électrode positive ; paroi externe : électrode négative)

- Conceptions d'électrodes personnalisées disponibles sur demande

| Matériau | Tension d'entraînement AC (V/mm) | Tension d'entraînement DC (V/mm) | Tension maximale personnalisable (V/mm) |

| PZT4 | 360 ~ 440 | 720 ~ 880 | Jusqu'à 1000 |

| PZT5 | 200 ~ 280 | 400 ~ 560 | |

| PZT8 | 360 ~ 440 | 720 ~ 880 |

Emballage en céramique PZT

Les produits en céramique PZT sont généralement emballés dans des sacs scellés sous vide pour éviter l'humidité ou la contamination et enveloppés de mousse pour amortir les vibrations et les chocs pendant le transport, ce qui garantit la qualité des produits dans leur état d'origine.

Télécharger

Obtenir un devis

Nous vérifierons et vous contacterons dans les 24 heures.