Substrat en nitrure d'aluminium

Substrat en nitrure d'aluminium

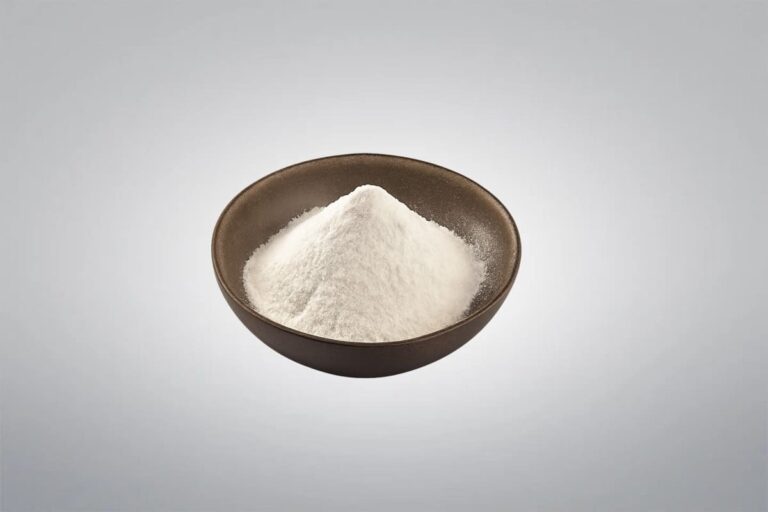

Pureté : 95%-99%

Le substrat en nitrure d'aluminium est un matériau céramique de haute performance doté d'une conductivité thermique exceptionnelle, d'une isolation électronique et d'une résistance aux températures élevées. Il est largement utilisé dans les dispositifs électroniques de haute puissance, les boîtiers de LED, les circuits à micro-ondes et les systèmes électroniques automobiles et aérospatiaux. En tant que fournisseur et fabricant de premier plan de produits en nitrure d'aluminium, nous pouvons fournir des substrats en nitrure d'aluminium de haute qualité avec diverses spécifications et des prix compétitifs, offrant des solutions personnalisées pour répondre à des exigences spécifiques.

Ou envoyez-nous un courriel à l'adresse suivante sales@heegermaterials.com.Fiche technique sur les substrats en nitrure d'aluminium

| Code de référence : | HM1914 |

| La pureté : | 95%-99% |

| Densité : | 3,32 g/cm3 |

| Apparence : | Gris foncé / Gris clair / Beige |

| Dimensions : | Sur mesure |

| Forme : | Rectangulaire, rond ou personnalisé |

| Finition de la surface : | Rugosité, polissage ou métallisation |

Substrat en nitrure d'aluminium

Le substrat en nitrure d'aluminium (AlN) est constitué d'une céramique de nitrure d'aluminium de haute pureté. Il permet une gestion thermique efficace dans les environnements à haute température, ainsi qu'une faible perte diélectrique et une excellente résistance aux chocs thermiques. Avancées Céramique Hub Nous pouvons fournir des options de moulage en vrac et de pièces uniques personnalisées pour répondre aux diverses exigences de l'industrie et de la recherche, avec une personnalisation souple et rapide de la taille et de l'échelle du produit.

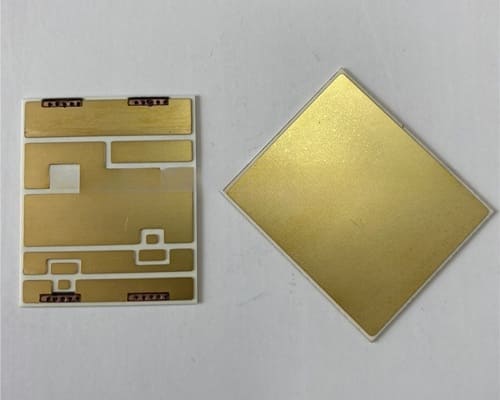

Substrat de nitrure d'aluminium avec trous Substrat en nitrure d'aluminium recouvert de cuivre

Propriétés des substrats en nitrure d'aluminium

| Objet | Unité | AlN-170 | AlN-190 | AlN-200 | AlN-230 | |

| Densité | g/cm3 | 3.3 | 3.3 | 3.28 | 3.3 | |

| Point de fusion | ℃ | 2500 | 2500 | — | — | |

| Rugosité de surface | μm | 0.2~0.6 | 0.3~0.5 | 0.2~0.5 | 0.2~0.6 | |

| Thermique | Conductivité thermique | 25℃ W/(m.k) | 170-190 | 190-210 | 204 | 233 |

| Coefficient de dilatation thermique | 20~300℃ (10-6/℃) | 4.6 | 4.6 | 4.0-5.0 | 4.0-5.0 | |

| Électricité | Constante diélectrique | 1 MHz, 25℃ | 8.56 | 8.56 | — | — |

| Perte diélectrique | 1 MHz, 25℃ | 4.6×10-4 | 4.6×10-4 | — | — | |

| Résistivité volumique | 20℃.Ω.cm | 1.4×1014 | 1.4×1014 | >1014 | >1014 | |

| Rigidité diélectrique | KV/mm | ≥15 | ≥15 | >20 | >20 | |

| Mécanique | Résistance à la flexion | Mpa | 300-400 | 300-400 | 350 | 300 |

| Module d'élasticité | GPa | 310-320 | 310-320 | — | — | |

| Les pages de guerre | ~/25(longueur) | ≤3‰ | ≤3‰ | ≤3‰ | ≤3‰ | |

Substrat de nitrure d'aluminium Spécifications standard

| Produit | Épaisseur | Longueur et largeur |

| 170W Produit standard | 0,381 mm | 4×4 pouces (101,6×101,6 mm) 4,5×4,5 pouces (114,3×114,3 mm) 120×120 mm 5×5 pouces (127×127 mm) 5,5×7,5 pouces (139,7×190,5 mm) |

| 0,5 mm | ||

| 0,635 mm | ||

| 1,0 mm | ||

| 1,5 mm | ||

| 170W Produit non standard | 0,1~0,2 mm | 2×2 pouces (50,8×50,8 mm) |

| 0,2~0,3 mm | 2×2 pouces (50,8×50,8 mm) 3×3 pouces (76,2×76,2 mm) 4×4 pouces (101,6×101,6 mm) 4,5×4,5 pouces (114,3×114,3 mm) | |

| 2,0~3,0 mm | ||

| 1,0~3,0 mm | 150 mm, 200 mm, 300 mm | |

| 200W | (0,3~0,38)±0,01 mm | 4,5×4,5 pouces (114,3×114,3 mm) |

| 230W | (0,3~0,38)±0,01 mm | 4,5×4,5 pouces (114,3×114,3 mm) |

Avantages des substrats en nitrure d'aluminium

- Conductivité thermique plus de 7 fois supérieure à celle de l'alumine.

- Coefficient de dilatation thermique proche de celui du silicium, garantissant une grande fiabilité pour le montage de grandes puces en silicium et la résistance aux cycles thermiques.

- Excellente isolation électrique avec une faible constante diélectrique.

- Résistance mécanique supérieure à celle de l'alumine.

- Excellente résistance à la corrosion des métaux en fusion.

- Teneur minimale en impuretés, non toxique et d'une grande pureté.

Applications des substrats en nitrure d'aluminium

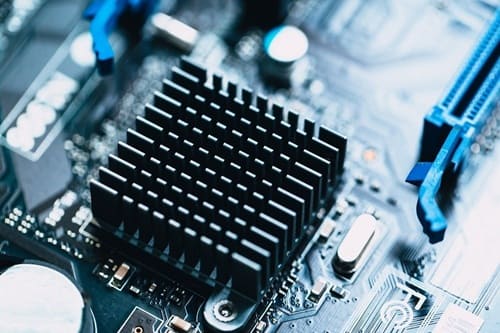

- Industrie électronique: Utilisés comme substrats pour les dispositifs électroniques de haute puissance (par exemple, les modules de puissance, les IGBT et les MOSFET), offrant une dissipation de la chaleur et une isolation électrique supérieures.

- Emballage LED: Utilisés comme substrats pour les puces LED, ils tirent parti d'une conductivité thermique élevée pour améliorer la dissipation de la chaleur et prolonger la durée de vie de l'appareil.

- Micro-ondes et RF: Utilisés comme substrats dans les circuits à micro-ondes et les dispositifs RF en raison de leur faible perte diélectrique et de leur grande stabilité thermique.

- Électronique automobile: Appliqué dans les convertisseurs de puissance et les modules de contrôle des véhicules électriques pour améliorer la gestion thermique et la fiabilité.

- Aérospatiale: Utilisé dans les systèmes électroniques à haute température et à haute fiabilité comme substrat pour les composants critiques.

Propriétés du nitrure d'aluminium

Nuances de nitrure d'aluminium

HMAN1000 est notre nitrure d'aluminium standard de haute pureté avec une conductivité thermique de 170 W/mK. Il s'agit de la même performance thermique que notre matériau de substrat, mais il offre la possibilité de produire des pièces plus grandes en longueur/largeur et d'une épaisseur allant jusqu'à 30 mm.

Le HMAN1000 a un bon coefficient de dilatation thermique - comparable à celui du silicium et du nitrure de gallium sur de larges plages de température.

HMAN100 Applications :

- Isolateurs de haute puissance

- Composants laser

- Dissipateurs thermiques refroidis à l'eau

- Électronique de puissance

- Composants aérospatiaux, médicaux et semi-conducteurs

HMAN1000S 170 W/mK est notre matériau de substrat standard à haute conductivité thermique, mais d'autres qualités à haute performance sont également disponibles.

HMAN1000S Applications :

- Dissipateurs de chaleur

- Diffuseurs de chaleur

- Dissipateurs de chaleur pour laser Redresseurs de puissance

- Aérospatiale, électronique de puissance, redresseurs

HMAN2000 est l'un de nos grades améliorés de nitrure d'aluminium, offrant toutes les performances mécaniques de HMAN1000 avec les avantages supplémentaires d'une conductivité thermique de 200 W/mK.

Applications HMAN2000:

- Dissipateurs de chaleur

- Diffuseurs de chaleur

- Dissipateurs de chaleur pour laser Redresseurs de puissance

- Aérospatiale, électronique de puissance, redresseurs

HMAN3000 est l'un de nos grades améliorés de nitrure d'aluminium offrant toutes les performances mécaniques de HMAN1000 avec les avantages supplémentaires d'une conductivité thermique de 230 W/mK.

HMAN3000 Applications :

- Dissipateurs de chaleur

- Diffuseurs de chaleur

- Dissipateurs de chaleur pour laser Redresseurs de puissance

- Aérospatiale, électronique de puissance, redresseurs

HMAN4000 est l'un de nos grades améliorés de nitrure d'aluminium offrant toutes les performances mécaniques de HMAN1000 avec les avantages supplémentaires d'une conductivité thermique de 200 W/mK.

HMAN4000 Applications :

- Dissipateurs de chaleur

- Diffuseurs de chaleur

- Dissipateurs de chaleur pour laser Redresseurs de puissance

- Aérospatiale, électronique de puissance, redresseurs

Usinage de la céramique de nitrure d'aluminium

L'usinage des céramiques de nitrure d'aluminium (AlN) est un processus précis utilisé pour fabriquer des composants de haute performance à partir de matériaux à base de nitrure d'aluminium. L'usinage des céramiques de nitrure d'aluminium nécessite un équipement et des techniques spécialisés pour gérer leur fragilité et leur dureté. Un outillage approprié et des environnements contrôlés sont essentiels pour éviter d'endommager le matériau et obtenir l'état de surface et la précision dimensionnelle souhaités. Les méthodes d'usinage courantes sont les suivantes :

- Coupe de diamants : Les outils diamantés sont utilisés pour obtenir une précision fine et des finitions de surface lisses, idéales pour les formes complexes.

- Découpe au laser : Une méthode sans contact utilisée pour les formes complexes, avec une grande précision et un impact thermique minimal.

- Meulage de précision : Utilisé pour obtenir des tolérances et des finitions de surface fines. Nécessite une attention particulière pour éviter les fissures ou les éclats en raison de la fragilité de la céramique.

- L'électroérosion à fil (EDM) : Méthode souvent utilisée pour les découpes complexes, en particulier pour les géométries fines et complexes.

Emballage en céramique de nitrure d'aluminium

Les produits en céramique de nitrure d'aluminium sont généralement emballés dans des sacs scellés sous vide pour éviter l'humidité ou la contamination et enveloppés de mousse pour amortir les vibrations et les chocs pendant le transport, ce qui garantit la qualité des produits dans leur état d'origine.

Télécharger

Obtenir un devis

Nous vérifierons et vous contacterons dans les 24 heures.