How to Break the Impasse in Cooling for Future High-Performance Chips?

Imagine a world where the blazing speed of artificial intelligence (AI) chips is throttled not by computational limits, but by an invisible enemy: heat. As of 2025, AI accelerators are pushing power densities to unprecedented levels, exceeding 1 kW/cm² in some hotspots, generating enough thermal output to rival a small space heater crammed into a fingernail-sized area. This isn’t hyperbole—it’s the stark reality facing the semiconductor industry, where Moore’s Law, once a beacon of exponential progress, now collides with the “thermal wall.” Chips are shrinking, transistors are denser, yet the heat they produce isn’t dissipating fast enough, leading to performance throttling, reduced lifespan, and skyrocketing energy costs in data centers.

Traditional cooling methods, designed for power envelopes of yesteryear, are buckling under the weight of exascale computing demands. Data centers alone consumed over 2% of global electricity in 2024, with projections for 2025 showing a 20% surge driven by AI workloads. Without breakthroughs, we will not only see inefficiency but also a full-blown crisis—delayed AI innovations, unsustainable energy footprints, and barriers to next-generation applications like autonomous vehicles and personalized medicine.

A single hyperscale data center can guzzle 100 MW of power, equivalent to a mid-sized city’s needs. Effective cooling isn’t just engineering—it’s the linchpin for sustainable computing.

En Centro de cerámica avanzadaEstamos especializados en técnico cerámica productos con una gran variedad de materiales y especificaciones, lo que garantiza un rendimiento óptimo para aplicaciones industriales y científicas.

What Are the Reasons for Chip Heat Generation?

Chip heat generation primarily results from the following factors:

- Power Consumption Generates Heat: When a chip operates, it consumes electrical energy. While some of this energy is converted into functionality, a portion of it is lost as heat, which is the fundamental cause of chip heating.

- Resistive Heating Due to Current Flow: Inside the chip, a large number of electrons flow. As current passes through the chip’s conductors, the inherent resistance of the conductors generates resistive heat, causing the chip’s temperature to rise.

- Electron Migration Converts to Heat Energy: Within the chip, electrons collide with atoms during their migration. These collisions convert the electrons’ kinetic energy into heat, further increasing the chip’s temperature.

- Heat Generated by Transistor Switching: Modern processors use transistors as basic logic units. When transistors switch states rapidly, they generate heat as a byproduct of the switching process.

- Design Factors Impact Heat Generation: The chip’s design is also a critical factor influencing its heat production. For example, higher chip density, more complex circuits, and smaller transistor sizes can all contribute to increased heat generation.

- Poor Cooling Leads to Excessive Heat: If the chip’s cooling system (such as heatsinks, fans, thermal paste, etc.) is poorly designed or inadequately maintained, it can prevent heat from dissipating efficiently, causing the chip’s temperature to rise.

The Current Cooling Impasse of Chips

The “cooling impasse of chips” refers to the critical challenge where the relentless progress of Moore’s Law continues to increase transistor density and computing power, but traditional cooling technologies (primarily air cooling) are approaching their physical limits. They can no longer effectively and efficiently dissipate the immense heat generated by chips, thereby constraining further performance gains. This has become one of the most severe challenges in high-performance computing, data centers, and consumer electronics.

Core Issues of the Impasse:

- Explosive Growth in Power Density: The power density (heat generated per unit area) of chips has skyrocketed. The heat flux of some high-performance chips has surpassed that of nuclear reactors. Traditional heat sinks and fans cannot remove such concentrated heat from the chip surface quickly enough.

- The “Thermal Wall”: Inability to dissipate heat leads to a rapid rise in the chip’s junction temperature. When the temperature exceeds a certain threshold (typically 80-100°C), the chip protects itself by throttling its performance (Thermal Throttling), leading to reduced speed. More critically, high temperatures accelerate electromigration, shortening chip lifespan and potentially causing immediate failure. This performance ceiling set by heat is known as the “thermal wall.”

- Energy Efficiency Bottleneck: Cooling systems themselves consume vast amounts of electricity in facilities like data centers. PUE (Power Usage Effectiveness) is a key metric for data center efficiency, with 1.0 being ideal. Inefficient cooling increases PUE, meaning more electricity is used for cooling rather than computation. This not only increases operational costs but also runs counter to global carbon neutrality goals.

Here’s a comparative table of legacy cooling approaches:

| Método de refrigeración | Max Power Density (W/cm²) | Pros | Contras | Suitability for 2025 HPC |

| Air Cooling (Fans/Heatsinks) | 100-150 | Low cost, easy retrofit | High noise, poor efficiency at scale | Low (legacy servers) |

| Tubos de calor | 200-300 | Passive, compact | Limited heat transfer, hotspot issues | Medium (GPUs) |

| Single-Phase Liquid | 300-500 | Better than air, scalable | Pump energy overhead, corrosion risks | Medium (AI clusters) |

| Two-Phase Evaporative | 500+ | High latent heat absorption | Complex plumbing, fluid compatibility | Emerging (data centers) |

These limitations ripple through industries. In high-performance computing (HPC), overheating has caused cascading failures, like the 2024 downtime at a major cloud provider that cost millions in lost revenue. Data centers, now AI powerhouses, face grid strains—Northern Virginia’s facilities alone drew 25% more power in 2025 than in 2023. For consumers, it means pricier, bulkier hardware; for the planet, it spells higher carbon emissions, as cooling alone accounts for 40% of data center energy use.

The impasse isn’t inevitable—it’s a call to evolve. Yet without addressing these pain points, the semiconductor boom, projected to hit $1 trillion in sales by 2030, risks stalling at the thermal gate.

Emerging Cooling Technologies in Heat Dissipation for High-Performance Chips

The insatiable demand for higher computing performance, driven by AI, HPC, and advanced gaming, has pushed air cooling to its physical limits. As chip power densities soar beyond 100 Watts per square centimeter—a heat flux rivaling a rocket nozzle—innovative thermal management is no longer a luxury but a necessity. The following emerging technologies are poised to redefine the landscape of chip cooling.

1. Advanced Liquid Cooling

This category moves beyond simple cold plates to more integrated and efficient solutions.

- Microfluidic & On-Chip Liquid Cooling: This is the frontier of liquid cooling. Instead of a cold plate on top of the chip, microscopic channels are etched directly into the silicon die or the interposer. Coolant (often deionized water) flows through these microchannels, removing heat at the very source. This is considered a key enabler for 3D-stacked chips, where dissipating heat from the inner layers is otherwise nearly impossible.

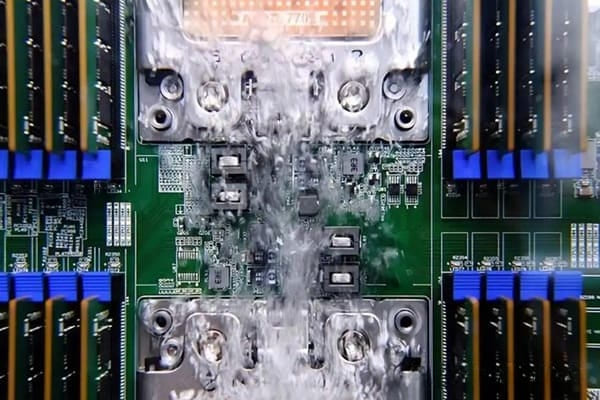

- Two-Phase Immersion Cooling: Entire servers are submerged in a dielectric fluid with a very low boiling point (e.g., 50°C). The heat from the chips causes the liquid to boil directly on their surface. The vapor rises, condenses on a heat exchanger, and falls back as liquid. The phase change (liquid to gas) absorbs a massive amount of heat efficiently and operates at near-silent levels. This is gaining rapid traction in data centers for its superior efficiency and ability to handle extreme loads.

2. Solid-State & Passive Cooling

These technologies offer silent, reliable cooling with no moving parts.

- Vapor Chambers & Advanced Heat Spreaders: While not entirely new, their application is becoming more sophisticated. Ultra-thin vapor chambers are now being integrated directly into device casings (like smartphones) or used as interposers between chiplets in a package to laterally spread heat more effectively than solid copper.

- Graphene and Advanced Thermal Interface Materials (TIMs): Graphene and its derivatives (like Graphite pads) possess exceptional in-plane thermal conductivity, far surpassing copper. They are being used as heat spreaders and as TIMs to fill microscopic gaps between the chip and the heat sink, drastically reducing thermal resistance at this critical junction.

- Electrostatic & Ionic Wind Cooling: This technology uses a high voltage to create a “wind” or flow of ions from a sharp electrode (corona discharge). This ionic wind stirs the air boundary layer that typically insulates hot surfaces, enhancing convective heat transfer significantly without noisy mechanical fans. It’s being explored for compact electronics where fan noise and size are constraints.

3. Cryogenic & Revolutionary Concepts

These are more futuristic but hold promise for extreme scenarios.

- Junction Cooling / Conductive Cooling: Similar to Peltier coolers but more advanced, this involves using materials with high electron mobility to “suck” heat away from the chip via its electrical connections. It’s a form of active, solid-state cooling being researched at the microscopic level.

- Chip-Integrated Thermoelectric Cooling: Miniaturizing thermoelectric (Peltier) coolers and integrating them directly onto the chip package. This allows for active, precise spot-cooling of hot spots, though challenges remain in efficiency and power consumption.

- Photonic Cooling: An experimental technique that uses lasers to cool a microscopic object by carefully tuning the laser’s frequency. While not ready for macro-scale chip cooling, it demonstrates the novel physics being explored for future thermal management.

Conclusión

The thermal bottleneck is not the end of computational progress, but a catalyst for innovation. We are at the crossroads of a paradigm shift: from “compute-first, cool-later” to “thermal-aware co-design.” The path forward will not rely on a single silver bullet, but rather on a multi-faceted, interdisciplinary matrix of solutions—from microfluidic channels within the silicon itself to system-level immersion tanks and atomically-thin graphene heat spreaders.

Breaking the cooling impasse is about more than just maintaining clock speeds. It is the key to unlocking the future potential of AI, quantum computing, and personalized medicine. It is the critical link between exponential computational growth and global sustainability goals. Overcoming the thermal wall is essential not only for building faster machines but for architecting a more intelligent, efficient, and sustainable digital future. This silent “cooling race” will be as definitive of the next computing era as the pursuit of transistor density itself.

Para productos cerámicos de alta calidad, Centro de cerámica avanzada proporciona soluciones a medida y técnicas de mecanizado de precisión para diversas aplicaciones.

Looking for advanced ceramic products? Póngase en contacto con nosotros