Tube en carbure de bore

Tube en carbure de bore

Pureté : ≥99.5%

Le tube en carbure de bore est un matériau céramique haute performance de faible densité, d'une dureté, d'une résistance à l'usure et d'une stabilité thermique exceptionnelles. Des dimensions et des formes personnalisées sont disponibles. En tant que fournisseur et fabricant de premier plan de produits en carbure de bore, nous pouvons fournir des tubes en carbure de bore de haute qualité avec diverses spécifications et des prix compétitifs, en offrant des solutions personnalisées pour répondre à des exigences spécifiques.

Ou envoyez-nous un courriel à l'adresse suivante sales@heegermaterials.com.Fiche technique des tubes en carbure de bore

| La pureté : | ≥99.5% |

| Apparence : | Noir ou gris |

| Formule chimique : | B₄C |

| Densité : | 2,46-2,62 g/cm³ |

Tube en carbure de bore Description

Le carbure de bore est un matériau céramique d'une dureté exceptionnelle, proche de celle du diamant et du nitrure de bore cubique, généralement fabriqué par frittage. Les tubes en carbure de bore sont fabriqués à l'aide de procédés avancés, offrant des dimensions précises, des performances stables et des solutions personnalisées pour de multiples applications industrielles et de recherche.

Avantages des tubes en carbure de bore

- Dureté et résistance élevées

- Excellente résistance aux chocs thermiques

- Excellente inertie chimique

- Excellente résistance à l'usure

- Bonne résistance à la corrosion

- Résistance aux hautes températures

- Résistance élevée à la flexion

- Poids léger

Procédé de frittage sans pression de tubes en carbure de bore

- Préparation des matières premières: Utiliser des produits de haute pureté poudre de carbure de bore et des auxiliaires de frittage.

- Mélange de poudres: Mélanger uniformément la poudre et les adjuvants de frittage.

- Moulage: Donner à la poudre la forme souhaitée.

- Dégazage: Retirer les composants volatils afin d'éviter la formation de bulles ou de fissures.

- Frittage sans pression: Frittage à 1600-2000°C.

- Refroidissement et inspection: Laisser refroidir à température ambiante et vérifier la qualité.

Applications des tubes en carbure de bore

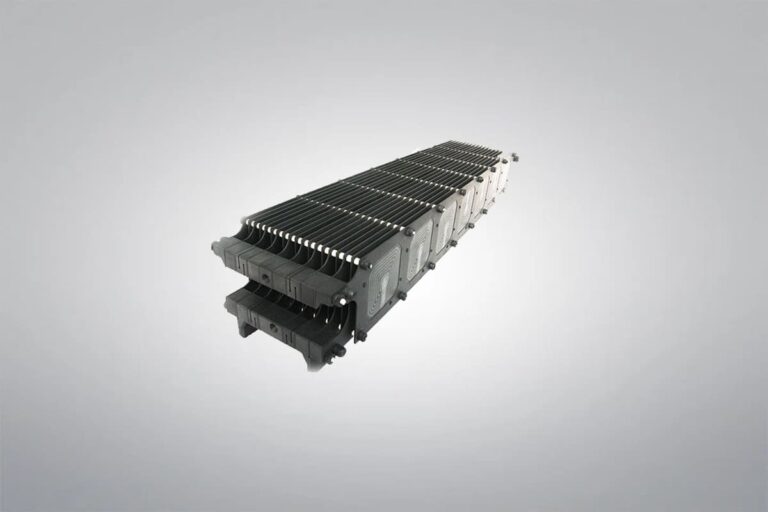

- Industrie nucléaire: Utilisés comme tubes absorbeurs de neutrons pour contrôler le flux de neutrons dans les réacteurs nucléaires.

- Armure de protection: Utilisé dans les tubes balistiques légers et très résistants pour la protection militaire et personnelle.

- Abrasifs et buses: Utilisées comme buses pour le sablage ou la découpe au jet d'eau, elles offrent une excellente résistance à l'usure pour les opérations à haute intensité.

- Industrie des hautes températures: Utilisés comme tubes de four ou tubes de protection des thermocouples, ils résistent à l'oxydation à haute température et à la corrosion chimique.

- Instruments de précision: Utilisés comme composants de tuyauterie résistants à l'usure et à la corrosion dans les équipements de haute précision.

Propriétés des matériaux en carbure de bore

Grades de matériaux en carbure de bore

Le carbure de bore lié par réaction (B4C) est principalement utilisé comme blindage balistique, offrant une excellente protection tout en réduisant le poids par rapport à d'autres matériaux de blindage.

| Propriétés | Unités | Reaction Bonded Carbure de bore |

| Résistance à la flexion, MOR (20 °C) | MPa | 250 |

| Résistance à la rupture, KIc | MPa m1/2 | 3.0 – 4.0 |

| Conductivité thermique (20 °C) | W/m K | 50 |

| Coefficient de dilatation thermique | 1×10-6/°C | 4.5 |

| Température maximale d'utilisation | °C | 1000 |

| Rigidité diélectrique (6,35 mm) | ac-kV/mm | - |

| Perte diélectrique (tan δ) | 1MHz, 25 °C | - |

| Résistivité volumique (25°C) | Ω-cm | 10³ |

Reaction Bonded B4C Avantages :

- Haute résistance

- Dureté élevée

- Rentabilité

- Convient aux applications à grande échelle

Le carbure de bore pressé à chaud, également connu sous le nom de densification assistée par pression (PAD), est l'un des matériaux les plus durs disponibles dans les formes commerciales. Cette dureté exceptionnelle, combinée à une faible densité, est utilisée dans les blindages balistiques, pour maximiser la protection tout en minimisant le poids.

| Propriétés | Unités | Pressé à chaud Carbure de bore |

| Résistance à la flexion, MOR (20 °C) | MPa | 320 – 450 |

| Résistance à la rupture, KIc | MPa m1/2 | 3.0 – 4.0 |

| Conductivité thermique (20 °C) | W/m K | 45 – 100 |

| Coefficient de dilatation thermique | 1×10-6/°C | 4.5 – 4.9 |

| Température maximale d'utilisation | °C | 2000 |

| Rigidité diélectrique (6,35 mm) | ac-kV/mm | - |

| Perte diélectrique (tan δ) | 1MHz, 25 °C | - |

| Résistivité volumique (25°C) | Ω-cm | 100 |

B4C pressé à chaud Avantages :

- Densité plus élevée

- Meilleures propriétés mécaniques

- Idéal pour les matériaux d'ingénierie à haute résistance et à haute température

Le carbure de bore fritté sans pression combine une grande pureté et les excellentes propriétés mécaniques du carbure de bore pour une utilisation dans les blindages balistiques et la fabrication de semi-conducteurs.

| Propriétés | Unités | Fritté Carbure de bore |

| Résistance à la flexion, MOR (20 °C) | MPa | 450 |

| Résistance à la rupture, KIc | MPa m1/2 | 3.0 – 5.0 |

| Conductivité thermique (20 °C) | W/m K | 43 – 100 |

| Coefficient de dilatation thermique | 1×10-6/°C | 4.5 – 4.9 |

| Température maximale d'utilisation | °C | - |

| Rigidité diélectrique (6,35 mm) | ac-kV/mm | - |

| Perte diélectrique (tan δ) | 1MHz, 25 °C | - |

| Résistivité volumique (25°C) | Ω-cm | 10 |

Avantages du B4C fritté sans pression:

- Dureté élevée

- Excellente résistance à l'usure

- Haute stabilité chimique

- Faible densité

- Bonne stabilité thermique

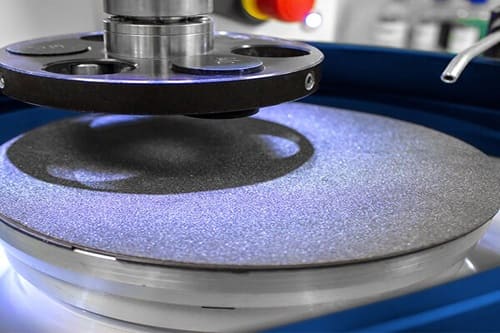

Usinage de la céramique de carbure de bore

L'usinage de la céramique de carbure de bore est un processus exigeant utilisé pour façonner cette céramique ultra-dure en composants précis pour des applications techniques. En raison de sa dureté et de sa fragilité exceptionnelles, l'usinage du carbure de bore nécessite des outils spécialisés et un contrôle minutieux pour éviter les fissures ou les dommages de surface. Bien que le matériau puisse être façonné plus facilement à l'état vert ou biscuit, l'obtention de tolérances serrées nécessite souvent un usinage après frittage complet, ce qui implique des techniques à base de diamant. Les méthodes d'usinage les plus courantes sont les suivantes :

- Coupe de diamants : Les outils revêtus de diamants sont essentiels pour couper le carbure de bore entièrement fritté, ce qui permet un façonnage précis et des finitions de surface lisses.

- Meulage de précision : Utilisé pour obtenir des tolérances fines et des finitions propres. Ce processus est lent et nécessite une manipulation soigneuse pour éviter les microfissures ou les dommages structurels.

- Usinage par ultrasons : Applique des vibrations à haute fréquence avec une boue abrasive pour enlever la matière en douceur, ce qui convient aux formes complexes et délicates.

- Découpe au laser : Une technique sans contact efficace pour les matériaux pré-frittés ou les sections minces, offrant des bords nets avec une contrainte thermique minimale.

- Usinage vert : Effectué avant le frittage, il permet de façonner plus facilement des géométries complexes. Cependant, le retrait post-frittage (~20%) doit être pris en compte dans les dimensions finales.

Emballage en céramique de carbure de bore

Les produits céramiques en carbure de bore sont généralement emballés dans des sacs scellés sous vide pour éviter l'humidité ou la contamination et enveloppés de mousse pour amortir les vibrations et les chocs pendant le transport, ce qui garantit la qualité des produits dans leur état d'origine.

Télécharger

Obtenir un devis

Nous vérifierons et vous contacterons dans les 24 heures.