Poudre de carbure de bore

Poudre de carbure de bore

Pureté : 99%

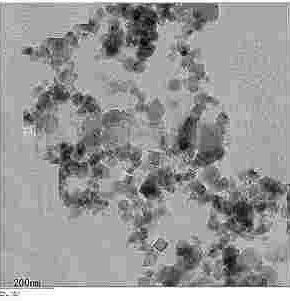

Taille des particules : 0,1 μm, 0,8 μm, 2,3 μm, ou personnalisée.

La poudre de carbure de bore est un matériau céramique très dur composé de bore et de carbone, communément représenté par la formule chimique B₄C. Avec une dureté Vickers supérieure à 30 GPa, il se classe parmi les matériaux connus les plus durs, juste après le diamant et le nitrure de bore cubique. Sa dureté exceptionnelle, sa faible densité et sa grande stabilité chimique en font un matériau clé dans un large éventail d'applications industrielles. Nous pouvons fournir des poudres de carbure de bore de haute qualité avec des spécifications variées et des prix compétitifs, en offrant des solutions personnalisées pour répondre à des exigences spécifiques.

Ou envoyez-nous un courriel à l'adresse suivante sales@heegermaterials.com.Fiche technique de la poudre de carbure de bore

| Code de référence : | HMCP-1705 |

| La pureté : | 99% |

| CAS : | 12069-32-8 |

| Couleur : | Gris foncé |

| Formule chimique : | B₄C |

| Taille des particules : | 0,1 μm, 0,8 μm, 2,3 μm, ou sur mesure. |

| Densité : | 2,508~2,512 g/cm3 |

| Point de fusion : | 2,350°C |

| Point d'ébullition : | 3500°C |

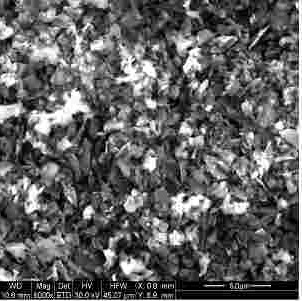

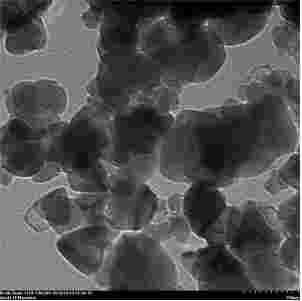

| forme : | Irrégulier |

Poudre de carbure de bore Description

La poudre de carbure de bore est connue pour sa très grande dureté, sa faible densité et sa résistance exceptionnelle à l'usure et à la corrosion chimique, ce qui en fait un matériau de choix pour les blindages balistiques, les abrasifs et les applications à haute température. La finesse de ses particules et la stabilité de ses propriétés chimiques garantissent des performances constantes dans le traitement des céramiques, les composites à matrice métallique et les applications nucléaires. En plus de cette forme de poudre irrégulière, nous fournissons également Poudre de carbure de bore sphériquequi offre une meilleure fluidité et une meilleure densité d'emballage pour la fabrication additive, la pulvérisation thermique et la métallurgie avancée des poudres.

Spécifications de la poudre de carbure de bore

| Produit | Composition chimique (%) | |||||

| B4C | B | C | N | O | ||

| 79.0 | 19.2 | 0.2 | 1.4 | |||

| Distribution de la taille des particules | ||||||

| D10 | D50 | D90 | ||||

| 0,1μm | 0,8μm | 2,3μm | ||||

| BET | ||||||

| 15 m2/g | ||||||

Avantages de la poudre de carbure de bore

- Dureté ultra-élevée

- Faible densité

- Excellente stabilité chimique

- Résistance thermique élevée

- Contrôle des particules fines

- Une gamme d'applications polyvalente

Applications de la poudre de carbure de bore

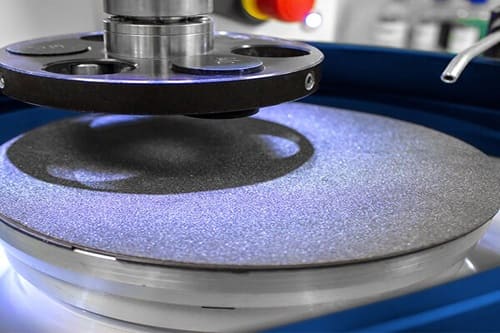

- Matériaux abrasifs : Utilisés dans les applications de meulage, de rodage et de polissage en raison de leur extrême dureté.

- Armure en céramique : Appliqué aux armures balistiques légères pour la protection militaire et personnelle.

- Composants résistants à l'usure : Utilisé pour produire des pièces techniques exposées à des environnements abrasifs et érosifs.

- Blindage neutronique : Il sert d'absorbeur de neutrons efficace dans les réacteurs nucléaires et de blindage contre les radiations.

- Avancé Céramique: Aide au frittage des céramiques de carbure de silicium et d'autres matériaux à haute performance.

Emballage de poudre de carbure de bore

La poudre de carbure de bore est soigneusement placée dans des caisses en bois ou des cartons avec un support supplémentaire en matériaux souples pour éviter tout déplacement pendant le transport. Cette méthode d'emballage garantit l'intégrité des produits tout au long du processus de livraison.

Télécharger

Obtenir un devis

Nous vérifierons et vous contacterons dans les 24 heures.