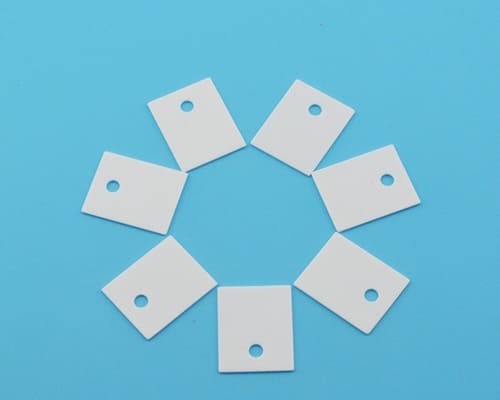

Substrat d'alumine

Substrat d'alumine

Pureté : 95%, 96%, 99%, 99.5%, 99.7%, 99.95%

Le substrat d'alumine est un matériau céramique de haute performance composé principalement d'oxyde d'aluminium de haute pureté (Al2O3), offrant une excellente conductivité thermique, une isolation électrique et une résistance aux températures élevées. En tant que fournisseur et fabricant de premier plan de produits d'alumine de qualité supérieure, nous pouvons fournir des substrats d'alumine de haute qualité avec diverses spécifications et des prix compétitifs, offrant des solutions personnalisées pour répondre à des exigences spécifiques.

Ou envoyez-nous un courriel à l'adresse suivante sales@heegermaterials.com.Fiche technique Substrat d'alumine

| Code de référence : | HM1979 |

| La pureté : | 95%, 96%, 99%, 99.5%, 99.7%, 99.95% |

| Dimensions : | 114,3×114,3 mm (4,5″×4,5″), 50,8×50,8 mm (2″×2″), ou sur mesure. |

| Épaisseur : | 0,25-2,0 mm, ou sur mesure |

| Couleur : | Blanc ou ivoire |

| Densité : | 3,7-3,98 g/cm3 |

Substrat d'alumine

Le substrat d'alumine est principalement constitué d'oxyde d'aluminium de haute pureté (Al2O3), largement utilisé dans l'emballage électronique, les modules de puissance, la dissipation thermique des LED et les circuits à haute fréquence. Il possède d'excellentes propriétés de conductivité thermique, d'isolation électrique et de résistance aux températures élevées, ce qui en fait le matériau de substrat le plus utilisé dans les circuits imprimés. Avancées Céramique Hub peut fournir des solutions personnalisées en termes de taille, de forme et de traitement de surface pour répondre aux diverses exigences de l'industrie et de la recherche.

Spécifications des substrats d'alumine

| Dimensions (Longueur × Largeur) : | 114,3×114,3 mm (4,5″×4,5″), 50,8×50,8 mm (2″×2″), ou sur mesure. |

| Épaisseur : | 0,25-2,0 mm, ou sur mesure |

| Conductivité thermique : | 24 W/m-K |

| Constante diélectrique : | 9-10 (MHz) |

| Densité en vrac : | 3,7 g/cm3 |

| Rugosité de la surface : | Ra:0,03-0,7 μm |

Caractéristiques du substrat d'alumine

Advanced Ceramic Hub sélectionne rigoureusement des matériaux d'alumine de haute pureté et fabrique les produits dans le cadre d'une gestion rigoureuse de la qualité, ce qui garantit une qualité constante et d'excellentes propriétés.

- Le matériau présente une structure à grain fin avec une porosité minimale, ce qui permet d'obtenir une surface parfaitement lisse et plane. Il présente également une excellente compatibilité avec les matériaux à couche épaisse et à couche mince.

- Les écarts de forme et d'épaisseur sont minimes.

- Le gauchissement, la flexion et les plis sont minimes.

- Dans les environnements à haute température, les propriétés physiques et chimiques restent stables, avec une excellente résistance aux chocs thermiques. Son coefficient de dilatation thermique est proche de celui du silicium et sa conductivité thermique est remarquable.

- Résistance mécanique exceptionnelle, avec des substrats renforcés à haute résistance disponibles.

- Excellente résistance à l'huile et aux produits chimiques.

- Propriétés d'isolation électrique exceptionnelles, avec une tension de claquage diélectrique, une résistance de surface et une résistance de volume élevées, ainsi qu'une faible constante diélectrique.

- Il existe également des substrats à haute réflectivité adaptés aux applications LED.

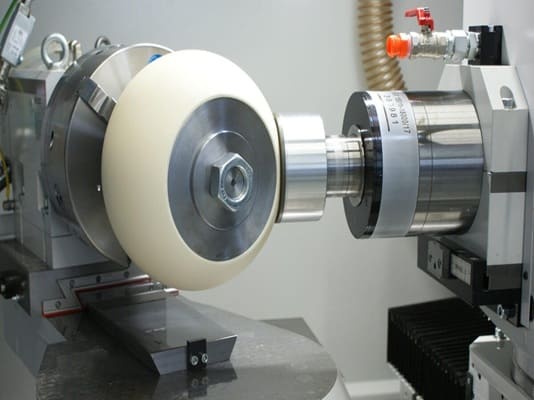

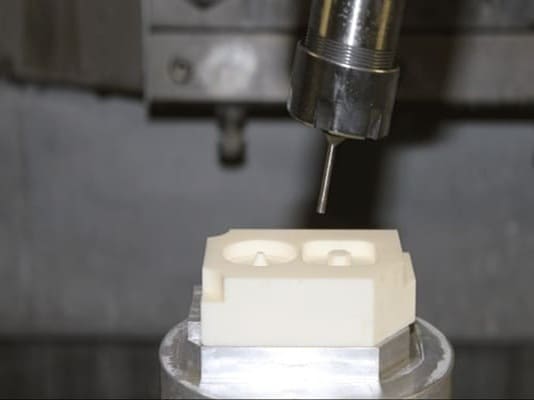

Substrat d'alumine Procédés d'usinage disponibles

- Traitement des glaçures

- Traitement au laser

- Multicouche

- Métallisation

- Traitement de l'estampage

- Meulage de surface

- Usinage

Substrats d'alumine Applications

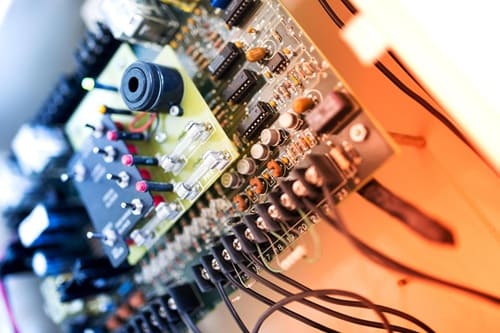

- Électronique: Dans les circuits intégrés, l'emballage des LED et les modules de puissance.

- Automobile: Comme substrats dissipateurs de chaleur dans les capteurs et les systèmes d'allumage.

- Dispositifs médicaux: Soutenir les composants électroniques biocompatibles.

- Aérospatiale: Support de circuit dans des environnements à haute température.

- Télécommunications: Circuits haute fréquence et dispositifs à micro-ondes.

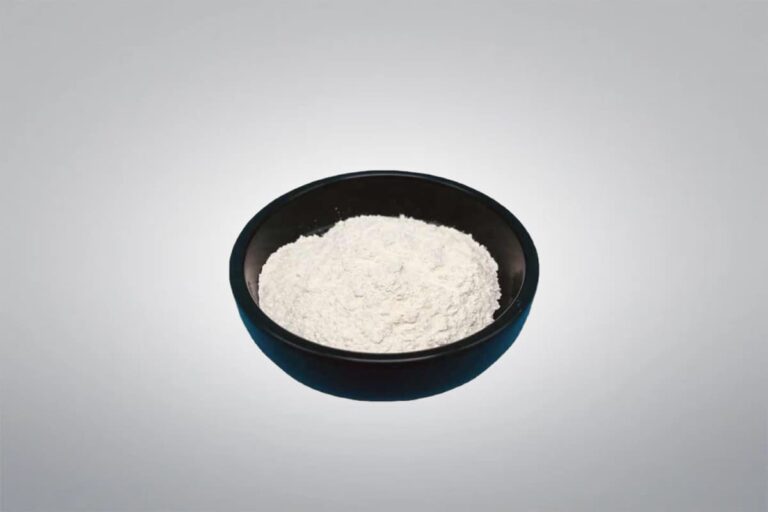

Propriétés de l'alumine

Grades de matériaux d'alumine

Il s'agit d'une qualité d'alumine (oxyde d'aluminium) d'une très grande pureté (99,95%) qui présente une combinaison exceptionnelle de propriétés mécaniques et électriques. Il présente une dureté très élevée, une résistivité électrique exceptionnelle, une stabilité mécanique et une résistance à haute température, ainsi qu'une résistance à la corrosion et une inertie biochimique.

Sa stabilité à haute température et sa stabilité électrique le rendent particulièrement adapté aux applications à haute température telles que les isolateurs haute tension/fréquence, les supports d'éléments chauffants, etc.

Propriétés physiques:

- Couleur : blanc

- Densité : 3,98 g/cm3

Applications :

- Isolants électriques à haute température

- Isolants à très haute tension/fréquence

- Composants de machines présentant une résistance élevée à l'usure

est nécessaire dans un environnement oxydant - Arbres de précision soumis à une forte usure

- Non lubrifié (sous vide) ou lubrifié au gaz/à l'eau

paliers lisses à grande vitesse - Buses de grenaillage

- Plaques/cônes déflecteurs de flux abrasifs

- Sièges de soupape

- Guides-fils

Il s'agit d'un grade d'alumine (oxyde d'aluminium) de haute pureté et de l'un des grades les plus performants de cette gamme de matériaux. Le matériau de base, l'alumine de pureté 99,7%, offre un ensemble supérieur de propriétés mécaniques et électriques tout en restant d'un coût raisonnable. Il s'agit d'une céramique technique très résistante qui convient parfaitement à un large éventail d'applications industrielles où les performances mécaniques et électriques sont essentielles et où le matériau doit fonctionner de manière adéquate dans des environnements agressifs.

Il peut être usiné à l'état vert, c'est-à-dire avant le frittage, ce qui permet d'obtenir une grande variété de formes et de tailles. Il peut également être rectifié au diamant pour obtenir des tolérances serrées à l'état entièrement fritté.

Propriétés physiques :

- Couleur : Ivoire

- Densité : 3,9 g/cm3

Applications:

- Composants électroniques et substrats

- Isolants électriques à haute température

- Isolateurs haute tension

- Tubes laser

- Composants usinés

- Joints mécaniques

- Arbres et essieux de précision dans des environnements à forte usure

- Roulements à rouleaux et à billes

- Joints d'étanchéité

- Pièces semi-conductrices

- Buses de grenaillage

- Tubes de thermocouple

- Plaques de robinetterie

- Sièges de soupape

- Composants d'usure

- Guides-fils et fils

- Armure balistique

L'alumine de pureté 99.5% est un matériau d'ingénierie de haute performance doté d'une résistance mécanique exceptionnelle, d'une résistance aux températures élevées et d'excellentes propriétés d'isolation électrique. Elle est largement utilisée dans les équipements industriels, les composants électroniques, les appareils médicaux et les applications aérospatiales.

Propriétés physiques :

- Couleur : Ivoire

- Densité : 3,9 g/cm3

Applications :

- Composants électroniques et substrats

- Isolants électriques à haute température

- Isolateurs haute tension

- Tubes laser

- Composants usinés

- Joints mécaniques

- Arbres et essieux de précision dans des environnements à forte usure

- Roulements à rouleaux et à billes

- Joints d'étanchéité

- Pièces semi-conductrices

- Buses de grenaillage

- Tubes de thermocouple

- Plaques de robinetterie

- Sièges de soupape

- Composants d'usure

- Guides-fils et fils

- Armure balistique

L'alumine de pureté 99% est un matériau céramique industriel de première qualité qui présente d'excellentes propriétés mécaniques, une dureté très élevée, une résistance aux températures élevées et des performances d'isolation. Il peut conserver des propriétés chimiques et physiques stables même dans des environnements extrêmes, ce qui le rend largement utilisé dans les semi-conducteurs, les composants électroniques, la technologie laser et l'aérospatiale.

Propriétés physiques :

- Couleur : Ivoire

- Densité : 3,85 g/cm3

Applications :

- Composants électroniques et substrats

- Isolants électriques à haute température

- Isolateurs haute tension

- Tubes laser

- Composants usinés

- Joints mécaniques

- Arbres et essieux de précision dans des environnements à forte usure

- Roulements à rouleaux et à billes

- Joints d'étanchéité

- Pièces semi-conductrices

- Buses de grenaillage

- Tubes de thermocouple

- Plaques de robinetterie

- Sièges de soupape

- Composants d'usure

- Guides-fils et fils

- Armure balistique

Il s'agit d'une alumine (oxyde d'aluminium) de pureté régulière qui constitue l'un des piliers de l'industrie des céramiques techniques. Son matériau de base, l'alumine de pureté 96%, offre un rapport coût/qualité équilibré. Il s'agit d'une céramique technique résistante qui offre une excellente combinaison de propriétés mécaniques et électriques et qui convient parfaitement à un large éventail d'applications industrielles où le coût est un facteur essentiel, mais où le matériau doit néanmoins présenter des performances mécaniques et électriques adéquates.

Il peut être usiné à l'état vert, c'est-à-dire avant le frittage, ce qui permet d'obtenir une grande variété de formes et de tailles. Il peut également être rectifié au diamant pour obtenir des tolérances serrées à l'état entièrement fritté.

Propriétés physiques :

- Couleur : blanc

- Densité : 3,75 g/cm3

Applications:

- Composants électroniques et substrats

- Isolants électriques à haute température

- Isolateurs haute tension

- Tubes laser

- Composants usinés

- Joints mécaniques

- Arbres et essieux de précision dans des environnements à forte usure

- Roulements à rouleaux et à billes

- Joints d'étanchéité

- Pièces semi-conductrices

- Buses de grenaillage

- Tubes de thermocouple

- Plaques de robinetterie

- Sièges de soupape

- Composants d'usure

- Guides-fils et fils

- Armure balistique

L'alumine pure 95% est un matériau d'ingénierie économique et pratique. Sa teneur en alumine légèrement inférieure réduit les coûts de production tout en conservant une bonne résistance à l'usure et une bonne flexibilité de traitement. Elle est couramment utilisée dans les pièces mécaniques, les isolateurs électriques et les bagues résistantes à l'usure, offrant un excellent rapport coût/performance.

Propriétés physiques :

- Couleur : blanc

- Densité : 3,7 g/cm3

Applications :

- Composants électroniques et substrats

- Isolants électriques à haute température

- Isolateurs haute tension

- Tubes laser

- Composants usinés

- Joints mécaniques

- Arbres et essieux de précision dans des environnements à forte usure

- Roulements à rouleaux et à billes

- Joints d'étanchéité

- Pièces semi-conductrices

- Buses de grenaillage

- Tubes de thermocouple

- Plaques de robinetterie

- Sièges de soupape

- Composants d'usure

- Guides-fils et fils

- Armure balistique

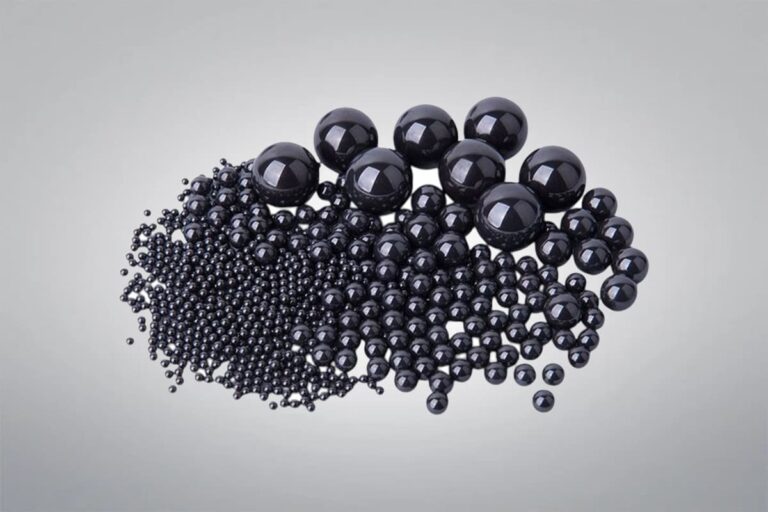

Usinage de la céramique d'alumine

Les céramiques d'alumine sont produites par des méthodes telles que le moulage par injection, le pressage sous pression, le pressage isostatique, le moulage par glissement et l'extrusion. Après le frittage et la densification, l'usinage nécessite des techniques de meulage au diamant. Advanced Ceramic Hub utilise la technologie de pointe de l'usinage en vert et en biscuit pour produire des composants plus complexes avec les méthodes traditionnelles. Notre centre d'usinage avancé comprend le perçage, la rectification, le fraisage, le polissage, le sciage, le taraudage, le filetage et le tournage, ce qui permet de fabriquer des composants en céramique d'alumine avec des tolérances serrées et une grande complexité. Pendant le processus d'usinage, les précautions suivantes doivent être observées :

- Contrôle de la rétraction: Les céramiques d'alumine se rétractent d'environ 20% pendant le frittage, ce qui nécessite des ajustements dimensionnels au stade du corps vert.

- Contrôle de la tolérance: Les tolérances précises sont impossibles à atteindre à l'état vert ou pré-fritté ; l'usinage fin doit suivre le frittage.

- Meulage au diamant: L'alumine à haute dureté après frittage nécessite un meulage au diamant, car les méthodes conventionnelles ne suffisent pas.

- Sélection des outils: Les outils ou les meules revêtus de diamants sont essentiels pour traiter la dureté de la céramique et éviter d'endommager l'outil.

- Contrôle de la température: Une gestion stricte de la température pendant le frittage permet d'éviter les fissures ou les déformations.

- Gestion du stress: Les contraintes excessives pendant l'usinage doivent être évitées afin de prévenir les ruptures fragiles.

- Vitesse de coupe et vitesse d'avance: Les vitesses et les avances contrôlées garantissent la qualité et prolongent la durée de vie de l'outil.

- Traitement de surface: Le polissage après usinage élimine les défauts, améliorant ainsi les performances et l'apparence.

Emballage en céramique d'alumine

Les produits en céramique d'alumine sont généralement emballés dans des sacs scellés sous vide pour éviter l'humidité ou la contamination et enveloppés de mousse pour amortir les vibrations et les chocs pendant le transport, ce qui garantit la qualité des produits dans leur état d'origine.

Télécharger

Obtenir un devis

Nous vérifierons et vous contacterons dans les 24 heures.