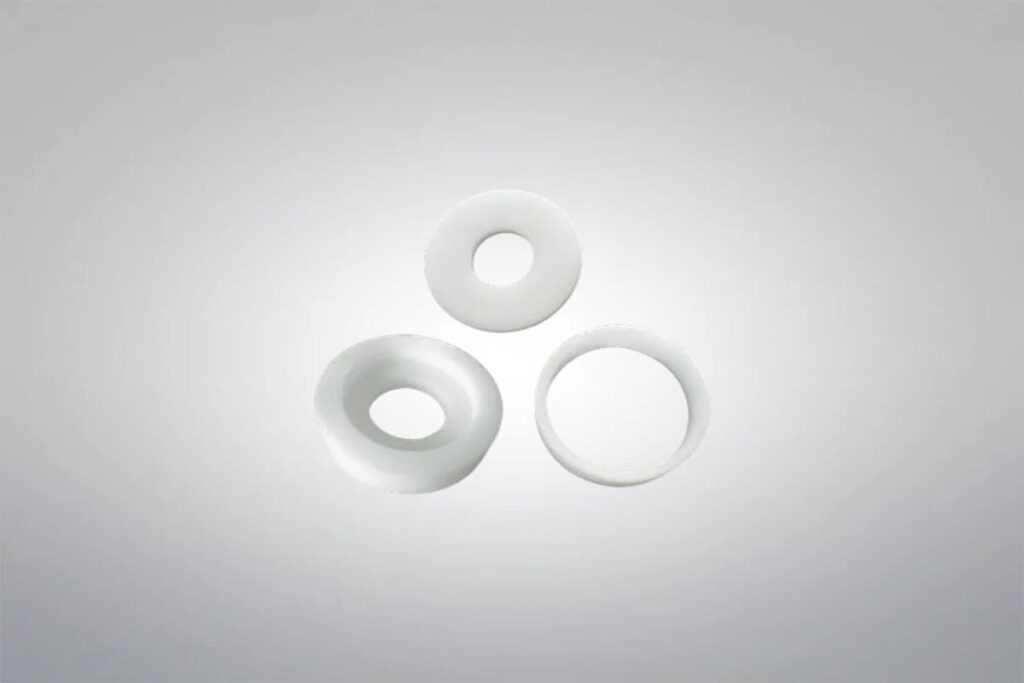

Quartz Ring For Etching Equipment

Quartz Ring For Etching Equipment

Purity: 99.99%

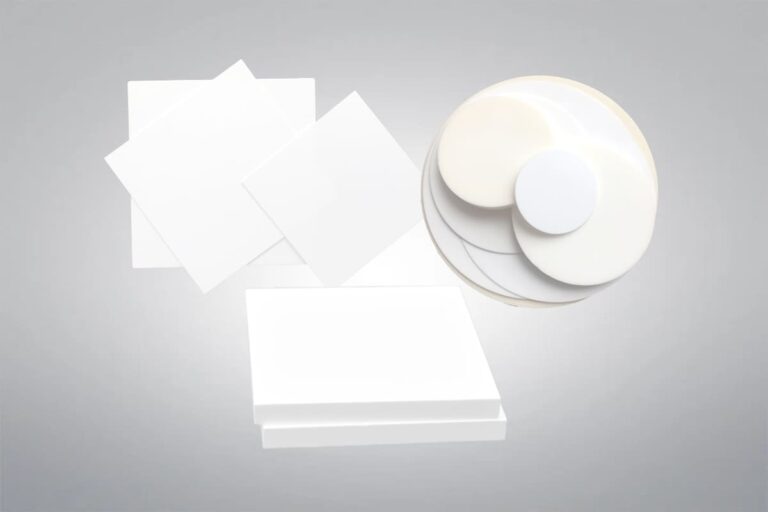

Quartz Ring For Etching Equipment is made from high-purity fused silica, offering exceptional thermal stability, low thermal expansion, and strong resistance to thermal shock. It maintains its strength and structure even under rapid temperature changes and harsh chemical environments. With excellent dielectric properties and high purity, quartz ceramic ring is widely used in semiconductor manufacturing, high-temperature insulation, and chemical processing systems. We can supply high-quality quartz ring for etching equipment with various specifications and competitive prices, offering customized solutions to meet specific requirements.

Or email us at sales@heegermaterials.com.Quartz Ring For Etching Equipment Data Sheet

| Color: | White – transparent |

| Dimension(inch): | 2, 4, or customized |

| Outer Dimeter(mm): | 50.8, 101.6 or customized |

| Thickness(mm): | 3, 4, or customized |

| Purity: | 99.99% |

Quartz Ring For Etching Equipment Description

Quartz ring for etching equipment is a high-purity, precision-engineered component designed for use in semiconductor etching processes. Made from synthetic or fused quartz, it offers excellent thermal shock resistance, low thermal expansion, and superior chemical stability in plasma environments. This makes it especially suited for reactive ion etching (RIE) and deep reactive ion etching (DRIE), where high purity and dimensional stability are critical. Its smooth surface finish and tight dimensional tolerances help maintain plasma uniformity, reduce particle contamination, and extend equipment life

Quartz Ring For Etching Equipment Features

- High purity: Composed of high-grade fused silica, ensuring low contamination and excellent thermal stability.

- Low thermal expansion: Maintains dimensional integrity even under rapid temperature changes.

- Excellent chemical resistance: Withstands acids and most corrosive environments.

- Superior dielectric properties: Ideal for high-voltage and high-frequency electrical insulation.

- Smooth surface finish: Reduces particle accumulation, suitable for cleanroom and semiconductor use.

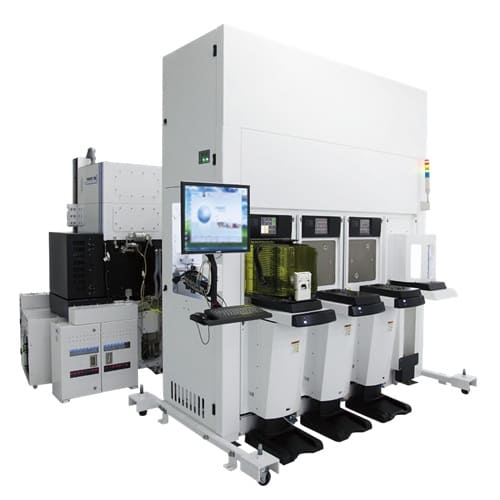

Quartz Ring For Etching Equipment Applications

- Semiconductor etching equipment: Supports wafer processing under high-temperature and plasma exposure.

- Reactive ion etching (RIE): Ensures uniform plasma distribution and high-precision patterning.

- MEMS fabrication: Suitable for deep etching applications in microelectromechanical systems production.

- Display panel manufacturing: Used in the plasma process for OLED and LCD production lines.

- Cleanroom processing: Compatible with ultra-clean environments due to low outgassing and high purity.

Quartz Ceramic Material Properties

| Purity (%) | >99.8 | >99.5 |

| Density (g/cm3) | 1.9-1.95 | 1.9-1.95 |

| Flexture strength (MPa) | 28 | 28 |

| Compressive strength (MPa) | >50 | >50 |

| Bending strength (MPa) | 25 | 25 |

| Maximum working temperature (℃) | 1650 | 1650 |

| Thermal conductivity (W/m*K) | <1 | <1 |

| Thermal expansion coefficient (/℃) | 8.5*10-7 | 8.5*10-7 |

| number of use | ≥10 | ≥10 |

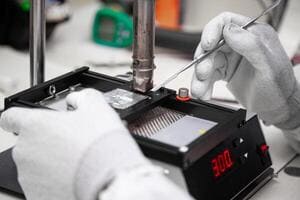

Quartz Ceramic Material Machining

Quartz ceramic material can be machined in its green or bisque state before sintering, making it easier to shape into complex forms. Like other ceramics, it shrinks by about 15–20% during sintering, so this must be considered in the initial design. After sintering, quartz ceramic becomes extremely hard and brittle, making machining very difficult and requiring diamond-coated tools and high-precision equipment.

Machining Methods and Considerations

- Green or Bisque Machining: Quartz ceramic is easier to cut and shape before sintering, making it suitable for intricate designs.

- Sintering Shrinkage: Expect a 15–20% size reduction during sintering, which affects dimensional accuracy.

- Post-Sintering Machining: After sintering, quartz becomes hard and brittle, requiring diamond tools and precise control.

- Fragility: Fully sintered quartz ceramic is prone to chipping or cracking if mishandled.

- Tooling and Time: Machining sintered quartz is slow and requires specialized equipment.

Quartz Ceramic Packaging

Quartz ceramic products are typically packaged in vacuum-sealed bags to prevent moisture or contamination and wrapped with foam to cushion vibrations and impacts during transport, ensuring the quality of products in their original condition.

Download

Get A Quote

We will check and get back to you in 24 hours.