Magnesium Oxide Tube

Magnesium Oxide Tube

Purity: ≥99%

Magnesium oxide tube is a high-purity ceramic known for its excellent thermal stability, electrical insulation, and corrosion resistance. With a melting point of 2800°C, it performs well in high-temperature environments, making it ideal for thermocouple protection, furnace insulation, and metal processing. Its low dielectric loss and high electrical resistivity also make it suitable for electrical applications. We can supply high-quality magnesium oxide tube with various specifications and competitive prices, offering customized solutions to meet specific requirements.

Or email us at sales@heegermaterials.com.Magnesium Oxide Tube Data Sheet

| Color: | White/Ivory |

| Chemical Formula: | MgO |

| Refractoriness: | Super high grade (Refractoriness > 2000°) |

| Density: | 3.30~3.55 g/cm3 |

| Melting Point: | 2800°C±13°C |

| Dimension: | customized |

| Working temperature: | 2400°C |

| Compressive strength: | 1000 MPa |

| Flexural strength: | 300 MPa |

| Surface: | Glass/Polished |

| Processing services: | Bending, welding, punching, decoiling, cutting, molding |

Magnesium Oxide Tube Description

Magnesium oxide tube is a refractory ceramic product known for its ability to withstand extreme heat and harsh chemical environments. With a high melting point and low electrical conductivity at room temperature, it’s an effective solution for insulating elements in high-temperature systems. These tubes are often used in scientific equipment, thermal processing lines, and nuclear-related applications where stability and purity are critical.

Magnesium Oxide Tube Features

- High temperature resistance up to 2400°C in oxidizing or inert atmospheres

- Excellent thermal insulation and low thermal conductivity

- High electrical resistivity at room temperature

- Chemically stable against most acids and basic slags

- Good compatibility with thermocouples and heating elements

Magnesium Oxide Tube Applications

- Thermocouple Protection: Acts as a protective sheath for thermocouples in high-temperature environments.

- Crucible Tubing: Used as crucible liners or reaction tubes in high-purity metal and ceramic processing.

- Insulating Components: Serves as an electrical insulator in high-voltage or high-frequency systems.

- Refractory Tubes: Function in furnaces and kilns where resistance to extreme heat is critical.

- Vacuum and Inert Atmosphere Processing: Ideal for operations requiring stable, non-reactive containers under vacuum or inert gas.

Magnesium Oxide Material Properties

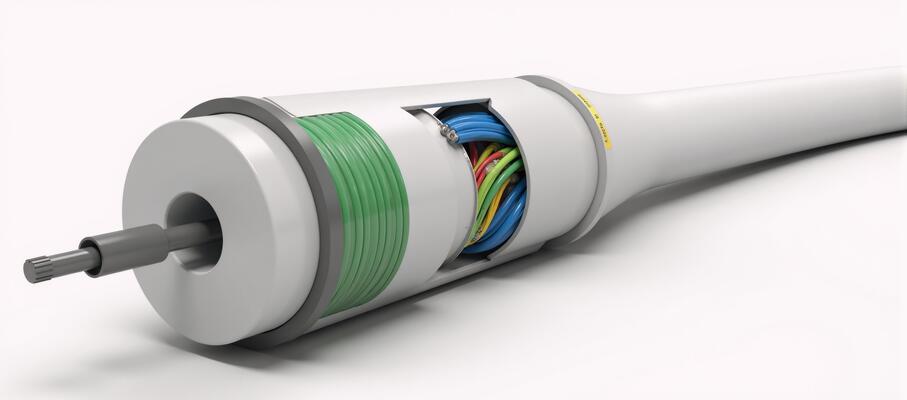

Magnesium Oxide Ceramic Machining

Magnesium oxide can be machined in green or bisque form before sintering, and to a limited extent in its fully sintered state. In its pre-sintered state, the material is relatively soft and easier to shape, but like many ceramics, it undergoes significant shrinkage—up to 20%—during sintering, which can affect final dimensions. Fully sintered magnesium oxide is very hard and brittle, requiring diamond tools and precision equipment for any post-sintering machining.

Machining Methods and Considerations

- Green or Bisque Machining: Easier to cut and form, suitable for complex shapes before firing.

- Sintering Shrinkage: Expect about 15–20% dimensional reduction during sintering, which impacts tolerance control.

- Post-Sintering Machining: Requires diamond grinding tools due to the material’s hardness and brittleness.

- Fragility: Fully sintered MgO is prone to chipping and fracture if not handled with care during machining.

- Tooling and Time: Machining dense MgO ceramics is time-consuming and requires specialized equipment.

Magnesium Oxide Ceramic Packaging

Magnesium oxide ceramic products are typically packaged in vacuum-sealed bags to prevent moisture or contamination and wrapped with foam to cushion vibrations and impacts during transport, ensuring the quality of products in their original condition.

Download

Get A Quote

We will check and get back to you in 24 hours.