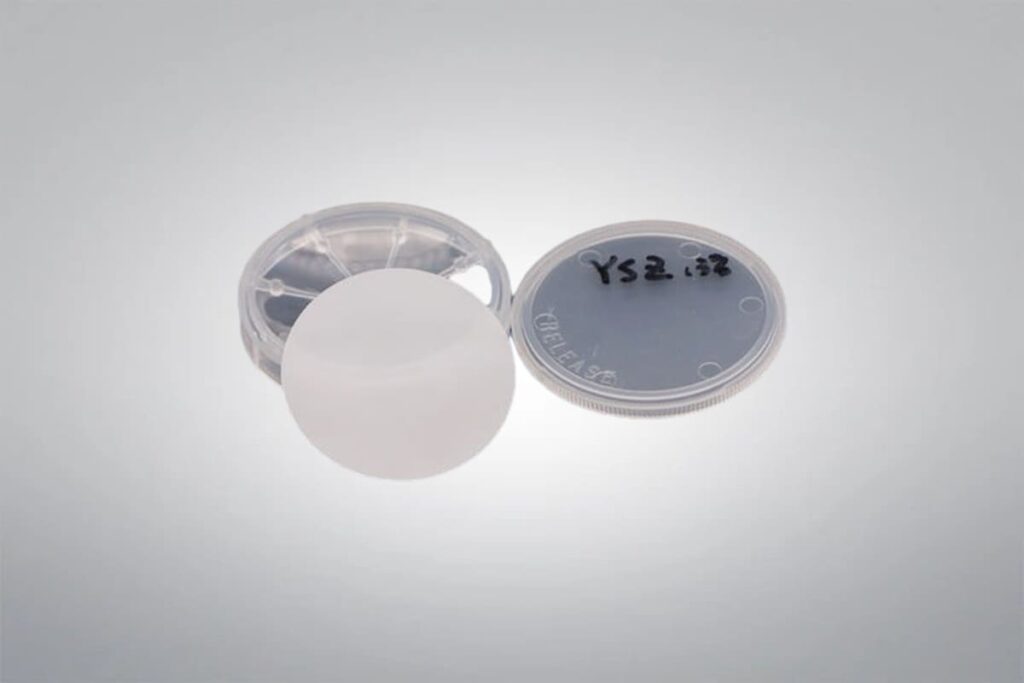

Yttria Stabilized Zirconia Crystal Substrate

Yttria Stabilized Zirconia Crystal Substrate

Yttria Stabilized Zirconia Crystal Substrate is a high-performance material formed by doping zirconium dioxide (ZrO₂) with approximately 19% yttria (Y₂O₃) to stabilize its cubic crystal structure. This single-crystal substrate offers excellent mechanical strength, thermal stability, and chemical resistance. Its stable crystal lattice and low thermal expansion make it suitable for high-temperature and high-vacuum applications. Widely used in electronics, optics, and solid oxide fuel cells (SOFCs), yttria stabilized zirconia crystal substrates are valued for their durability and consistent performance under demanding conditions. We can supply high-quality yttria stabilized zirconia crystal substrate with various specifications and competitive prices, offering customized solutions to meet specific requirements.

Or email us at sales@heegermaterials.com.Yttria Stabilized Zirconia Crystal Substrate Data Sheet

| Crystal Structure | Cubic |

| Lattice Constant | a = 5.147 Å |

| Melting Point (℃) | 2700 |

| Density (g/cm³) | 6.0 |

| Hardness (Mohs) | 8-8.5 |

| Purity | 99.99% |

| Thermal Expansion Coefficient (/℃) | 10.3 × 10⁻⁶ |

| Dielectric Constant (ε) | 27 |

| Growth Method | Arc Melting Method |

Yttria Stabilized Zirconia Crystal Substrate Description

Yttria stabilized zirconia crystal substrate provides a robust and stable platform for advanced electronic and energy devices. Its exceptional ionic conductivity and resistance to chemical corrosion make it ideal for use in solid oxide fuel cells, oxygen sensors, and other high-temperature electrochemical applications. Unlike polycrystalline ceramics, the single-crystal structure ensures uniform thermal and mechanical properties without grain boundary defects. The addition of yttria not only stabilizes the zirconia phase but also enhances thermal shock resistance, making this substrate a reliable choice for precision systems operating under extreme conditions.

Yttria Stabilized Zirconia Crystal Substrate Specifications

| Dimensions | 5×5, 10×3, 10×5, 10×10, 15×15, 20×15, 20×20, 25×25, or customized |

| dia 2” x 0.33 mm, dia 2” x 0.43 mm, dia 2” x 0.5 mm, or customized | |

| Thickness | 0.5 mm, 1.0 mm, or customized |

| Polishing | Single-sided or double-sided |

| Crystal Orientation | <001> ± 0.5° |

| Crystal Plane Orientation Precision | ± 0.5° |

| Edge Orientation Precision | 2° (special requirements can be achieved within 1°) |

| Cutting Angle (Off-Axis Wafers) | Can be custom-processed to specific edge orientation with tilt angles ranging from 1° to 45° |

| Surface Roughness (Ra) | ≤ 5 Å (5 µm × 5 µm) |

Yttria Stabilized Zirconia Crystal Substrate Features

- Excellent ionic conductivity: Enables efficient oxygen ion transport, making it ideal for high-temperature electrochemical devices.

- Superior thermal and chemical stability: Remains stable in oxidizing and reducing environments at temperatures above 1000°C.

- No grain boundaries: Single-crystal structure eliminates grain boundary defects, ensuring uniform performance.

- Low thermal expansion mismatch: Compatible with various electrode materials, reducing thermal stress during operation.

- High mechanical strength: Withstands thermal cycling and mechanical loads in demanding environments.

Yttria Stabilized Zirconia Substrate Applications

- Solid oxide fuel cells (SOFCs): Serve as the electrolyte or anode support due to high ionic conductivity and stability.

- Oxygen sensors: Used in automotive and industrial sensors for precise oxygen level detection.

- High-temperature electronics: Acts as a reliable substrate for semiconductors operating under thermal stress.

- Laser and photonic devices: Function as a stable base for optical coatings and laser reflectors.

- Vacuum insulation components: Ideal for use in ultra-high vacuum systems thanks to its low gas permeability.

Yttria Stabilized Zirconia Ceramic Properties

Yttria Stabilized Zirconia Ceramic Material Machining

Yttria Stabilized Zirconia (YSZ) is a high-performance ceramic material known for its exceptional fracture toughness, high strength, and ionic conductivity. These characteristics make it ideal for demanding environments, though its machining requires specialized approaches due to its hardness and brittleness. Key machining aspects include:

- Cutting: Diamond-coated tools or precision laser cutting are employed to maintain edge integrity and minimize microcracking.

- Grinding: Fine-grit diamond grinding is used to achieve tight tolerances and smooth surfaces, especially for components with complex geometries.

- Drilling: Ultrasonic machining or precision diamond drilling enables accurate formation of micro-features for sensor and fuel cell applications.

- Surface Finishing: Polishing enhances wear resistance, biocompatibility, and thermal stability, making it suitable for advanced engineering uses.

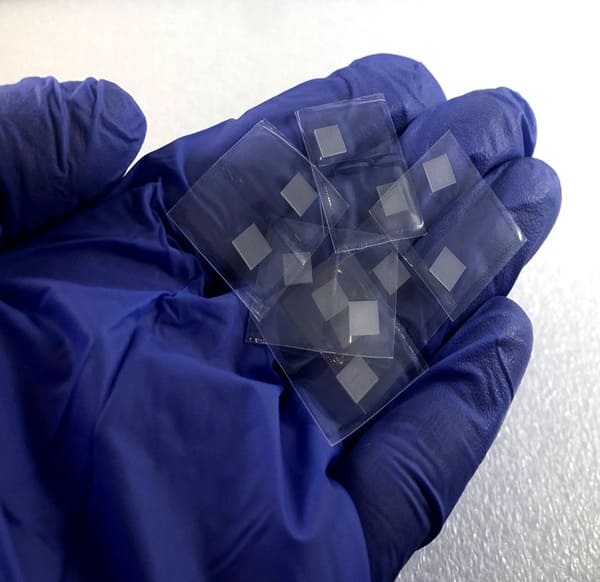

Yttria Stabilized Zirconia Ceramic Packaging

Yttria stabilized zirconia ceramic products are typically packaged in vacuum-sealed bags to prevent moisture or contamination and wrapped with foam to cushion vibrations and impacts during transport, ensuring the quality of products in their original condition.

Download

Get A Quote

We will check and get back to you in 24 hours.