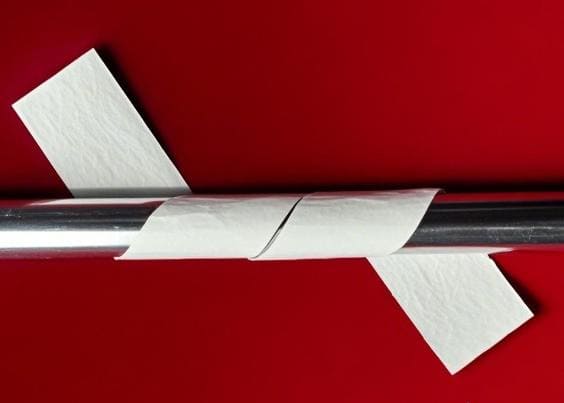

Oxidation-Resistant Release Paper

Oxidation-Resistant Release Paper

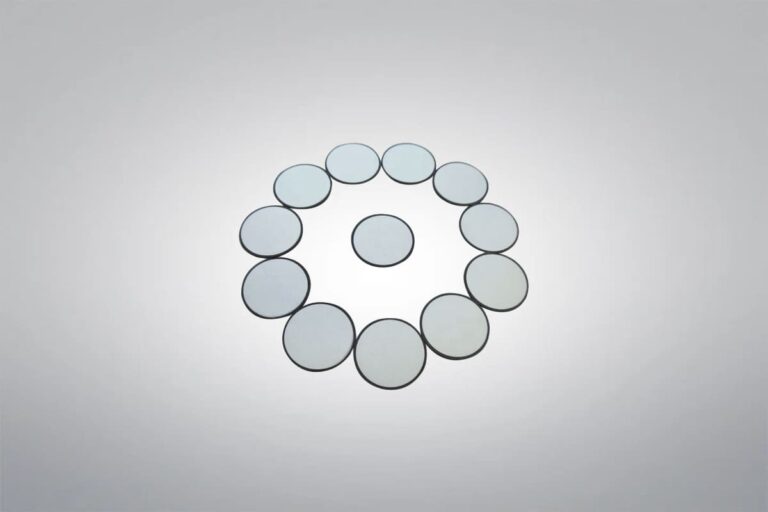

Oxidation-Resistant Release Paper is a high-purity material designed to withstand high temperatures while preventing sticking during industrial processing. Its stable, oxidation-resistant structure maintains integrity in demanding environments, making it suitable for sintering, metal casting, composite production, and other high-temperature applications. As a leading supplier and manufacturer of premium boron nitride products, we can supply high-quality Oxidation-Resistant Release Paper with various specifications and competitive prices, offering customized solutions to meet specific requirements.

Or email us at sales@heegermaterials.com.Oxidation-Resistant Release Paper Data Sheet

| Dimension: | Customized |

| Materials: | BN |

Oxidation-Resistant Release Paper Description

Oxidation-Resistant Release Paper Description: Oxidation-Resistant Release Paper is engineered from high-stability materials that maintain their structure and release performance even under prolonged exposure to high temperatures and oxidative environments. It helps prevent adhesion during thermal processing, ensuring clean separation in sintering, alloy casting, and composite molding.

Oxidation-Resistant Release Paper Specifications

| Test Item | Unit | Standard Value | Measured Value |

|---|---|---|---|

| Basis Weight | g/m² | 290±20 | 289 |

| Thickness | mm | 0.35±0.03 | 0.34 |

| Tensile Strength | KN/m | ≥0.2 | 0.3 |

| Breakdown Strength | kV/mm | ≥10 | 16 |

| Volume Resistivity | Ω·m | ≥4×10⁸ | 5.1×10⁹ |

| Moisture Content | % | ≤1 | 0.6 |

| Combustible Content | % | ≤3 | 2.5 |

| Minimum Bending Radius | mm | / | 20 |

| Thermal Conductivity | W/m·K | Measured | 0.553 |

Oxidation-Resistant Release Paper Applications

- High-Temperature Sintering: Provides a clean, non-stick layer for ceramic, metal, and powder sintering processes.

- Metal Casting: Prevents adhesion during alloy casting, ensuring smooth release and reducing cleanup time.

- Composite Manufacturing: Acts as a stable release layer in composite molding under oxidative and high-heat conditions.

- Thermal Processing Equipment: Used as a protective barrier in furnaces, heating systems, and other high-temperature tools.

- Advanced Material Research: Supports laboratory-level thermal experiments that require reliable, oxidation-resistant release performance.

Download

Get A Quote

We will check and get back to you in 24 hours.