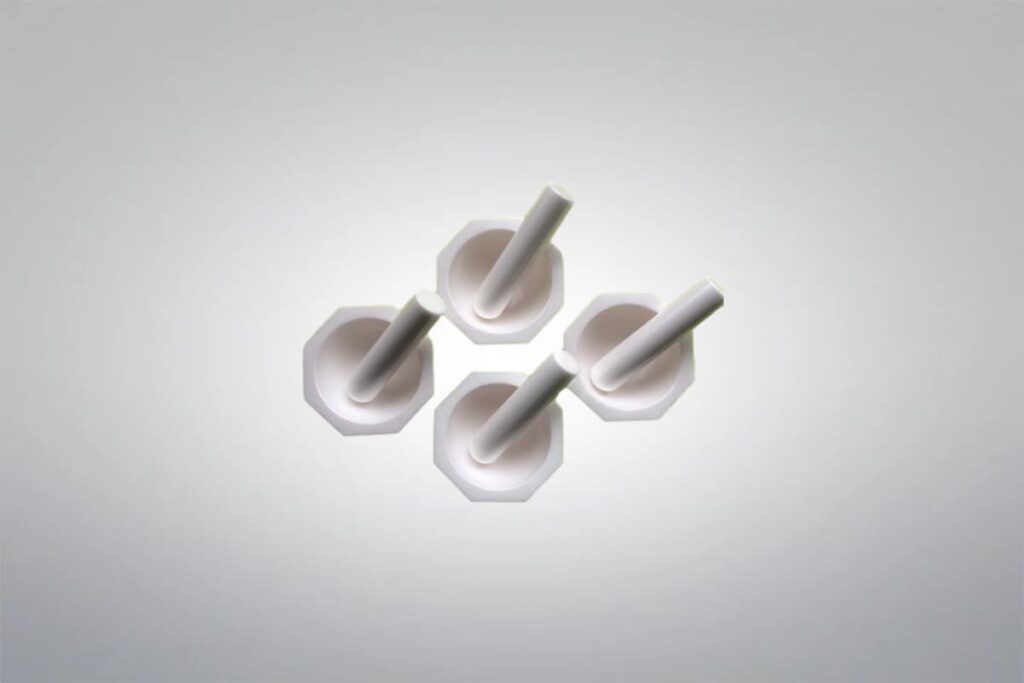

Ytrria Stabilized Zirconia Mortars and Pestles

Ytrria Stabilized Zirconia Mortars and Pestles

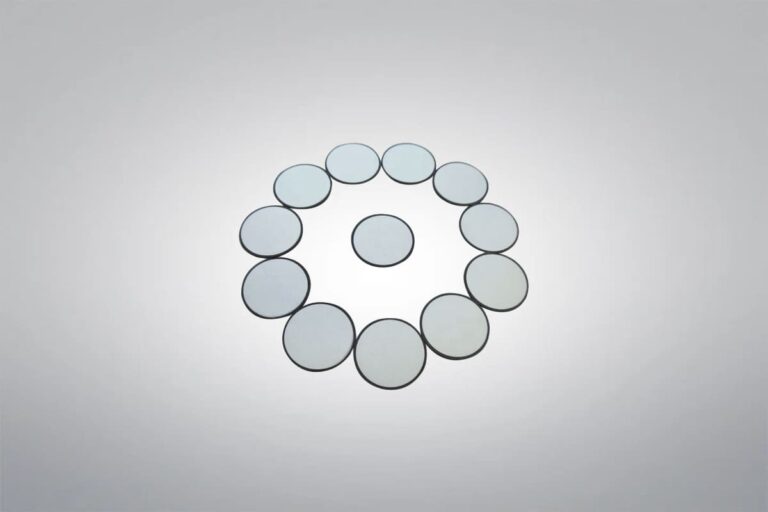

Yttria Stabilized Zirconia Mortars and Pestles are high-performance ceramic grinding tools engineered for applications that require exceptional hardness, corrosion resistance, and purity. Made from tetragonal phase-stabilized zirconia with yttria (Y₂O₃), they offer superior mechanical strength and are ideal for grinding hard, abrasive, or highly pure materials in research, pharmaceutical, and materials science settings. Their excellent resistance to acids, alkalis, and thermal shock ensures minimal contamination during sample preparation. We can supply high-quality yttria stabilized zirconia mortars and pestles with various specifications and competitive prices, offering customized solutions to meet specific requirements.

Or email us at sales@heegermaterials.com.Ytrria Stabilized Zirconia Mortars and Pestles Data Sheet

| Color: | White |

| Purity: | 99.9% |

| Dimension: | customized |

Ytrria Stabilized Zirconia Mortars and Pestles Description

Yttria stabilized zirconia mortars and pestles are precision-engineered ceramic tools designed for ultra-clean grinding processes. Thanks to their high fracture toughness and zero porosity, they are perfect for preparing fine powders without introducing impurities—ideal for semiconductor, battery, and biomaterial research. Unlike traditional alumina or agate tools, yttria-stabilized zirconia resists wear and chemical attack even under aggressive grinding conditions. This makes them especially suitable for crushing reactive or high-purity materials where contamination control is essential. Their smooth, dense surface also allows for easier cleaning and longer service life.

Yttria Stabilized Zirconia Ceramic Material Chemical Composition

| Composition | Content % |

| ZrO2 | 93.6 |

| MgO | 0.1 |

| CaO | 0.3 |

| Al2O3 | 0.3 |

| TiO2 | 0.1 |

| Fe2O3 | 0.1 |

| SiO2 | 0.3 |

| Y2O3 | 5.2 |

Ytrria Stabilized Zirconia Mortars and Pestles Features

- High Fracture Toughness: Excellent resistance to cracking and chipping under pressure, ideal for repeated use in grinding tasks.

- Chemical Inertness: Resistant to acids, alkalis, and solvents, preventing chemical contamination during sample preparation.

- Extreme Hardness: Significantly harder than alumina and agate, offering better performance in milling tough materials.

- Zero Porosity: Non-porous surface eliminates sample absorption and cross-contamination between uses.

- Thermal Stability: Withstands high temperatures, making it suitable for processing heat-sensitive or thermally reactive substances.

Yttria Stabilized Zirconia Mortars and Pestles Applications

- Pharmaceutical R&D: Grinding active ingredients without contamination in drug development labs.

- Battery Material Preparation: Mixing cathode/anode powders for lithium-ion and solid-state batteries.

- High-Purity Ceramics: Preparing zirconia, alumina, or silicon nitride powders for sintering.

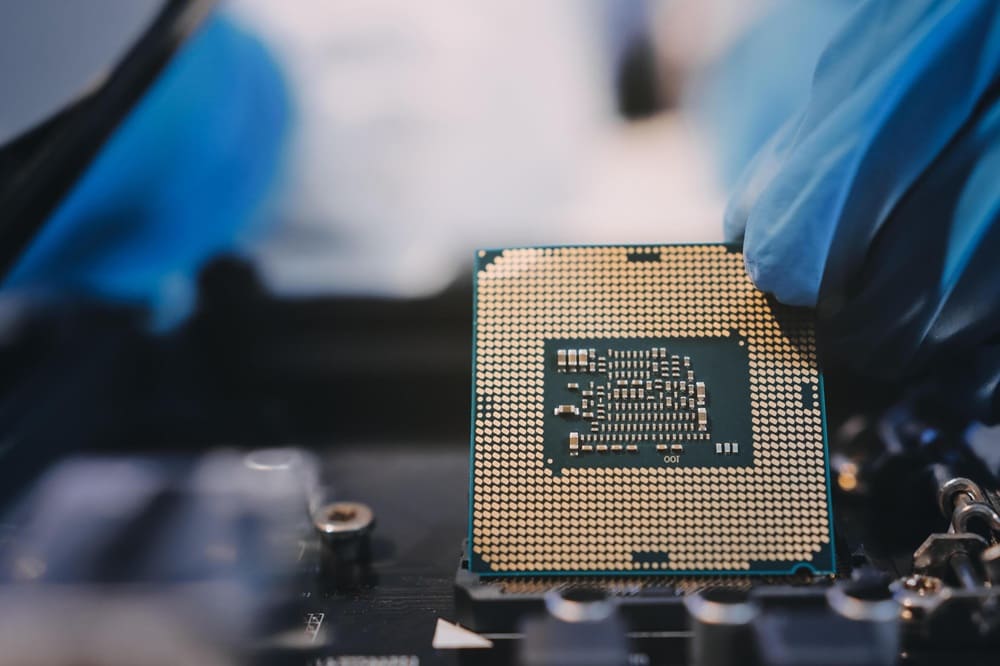

- Semiconductor Industry: Grinding rare earths or oxides under ultra-clean, particle-free conditions.

- Catalyst Research: Homogenizing metal oxides or zeolite powders for catalyst formulation.

Yttria Stabilized Zirconia Ceramic Properties

Yttria Stabilized Zirconia Ceramic Material Machining

Yttria Stabilized Zirconia (YSZ) is a high-performance ceramic material known for its exceptional fracture toughness, high strength, and ionic conductivity. These characteristics make it ideal for demanding environments, though its machining requires specialized approaches due to its hardness and brittleness. Key machining aspects include:

- Cutting: Diamond-coated tools or precision laser cutting are employed to maintain edge integrity and minimize microcracking.

- Grinding: Fine-grit diamond grinding is used to achieve tight tolerances and smooth surfaces, especially for components with complex geometries.

- Drilling: Ultrasonic machining or precision diamond drilling enables accurate formation of micro-features for sensor and fuel cell applications.

- Surface Finishing: Polishing enhances wear resistance, biocompatibility, and thermal stability, making it suitable for advanced engineering uses.

Yttria Stabilized Zirconia Ceramic Packaging

Yttria stabilized zirconia ceramic products are typically packaged in vacuum-sealed bags to prevent moisture or contamination and wrapped with foam to cushion vibrations and impacts during transport, ensuring the quality of products in their original condition.

Download

Get A Quote

We will check and get back to you in 24 hours.