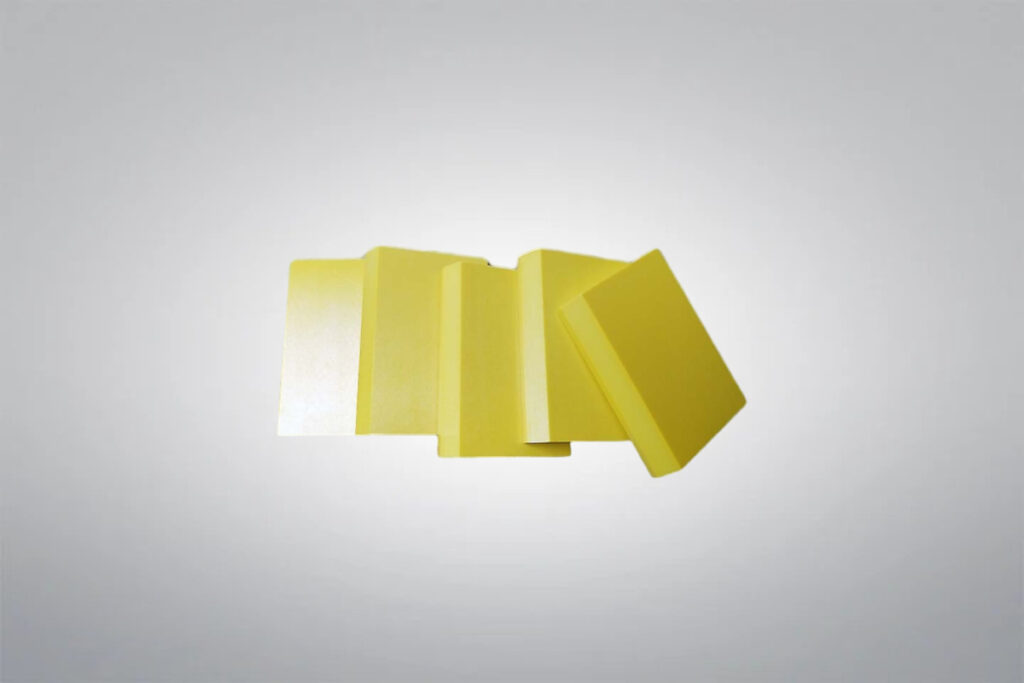

Magnesia Stabilized Zirconia Block

Magnesia Stabilized Zirconia Block

Magnesia Stabilized Zirconia Block is a high-performance ceramic material known for its exceptional mechanical strength and fracture toughness. With excellent wear resistance, low thermal conductivity, and good thermal shock stability, it performs reliably in harsh industrial environments. Its stability under mechanical and thermal stress makes it suitable for structural applications where durability and precision are essential. We can supply high-quality magnesia stabilized zirconia ceramic blocks with various specifications and competitive prices, offering customized solutions to meet specific requirements.

Or email us at sales@heegermaterials.com.Magnesia Stabilized Zirconia Block Data Sheet

| Color: | Yellow |

| Size: | Customized |

| Density (g/cm³): | 5.70 |

| Hardness (HV 0.5): | 1100 |

| Fracture Toughness (MPa·m¹/²): | 6-7 |

| Flexural Strength (@RT) (MPa): | 500 |

| Compressive Strength (@RT) (MPa): | 2000 |

| Thermal Conductivity (@RT) (W/mK): | 2.2 |

| Thermal Expansion Coefficient (20-1000℃) (10⁻⁶/℃): | 10.3 |

| Thermal Shock Resistance (ΔT℃): | 450 |

| Maximum Operating Temperature (@RT) (℃): | 2000 |

Magnesia Stabilized Zirconia Block Description

Magnesia stabilized zirconia block offers a robust combination of hardness and chemical resistance, making it ideal for demanding environments. It maintains structural integrity under prolonged use and exposure to aggressive media. This material is widely used in high-stress applications such as wear pads, nozzles, and insulating components due to its ability to resist deformation and maintain stability over time.

Magnesia Stabilized Zirconia Block Features

- High fracture toughness for excellent resistance to cracking and mechanical impact.

- Superior wear resistance, suitable for long-term use in abrasive environments.

- Strong thermal shock resistance ensures stability under rapid temperature fluctuations.

- Chemically inert to most acids, bases, and molten metals.

- Low thermal conductivity for effective heat insulation.

Magnesia Stabilized Zirconia Block Applications

- High-Temperature Refractory Structures: Used in kilns, crucibles, and thermal barrier systems due to excellent thermal resistance.

- Precision Mechanical Components: Ideal for bushings, sleeves, and wear-resistant parts in demanding industrial settings.

- Medical Devices: Applied in surgical instruments and implants for their biocompatibility and strength.

- Energy Equipment: Utilized in solid oxide fuel cells and insulation parts in power systems.

- Optical and Electronic Assemblies: Functions as a stable support or insulator in fiber optics and electrical modules.

Magnesia Stabilized Zirconia Ceramic Machining

Magnesia Stabilized Zirconia Ceramic Machining

Magnesia stabilized zirconia (MSZ) ceramics can be machined before sintering (green or bisque state) and, to a much lesser extent, after full densification. In the green state, the material is softer and easier to process, allowing for shaping and drilling of intricate features. However, sintering leads to a predictable shrinkage of around 15–20%, requiring adjustments in the initial design to meet final tolerances. Once fully sintered, MSZ becomes extremely hard and wear-resistant, making machining difficult and limited to precision diamond grinding.

Machining Methods and Considerations

- Green/Bisque Machining: Enables efficient shaping and forming prior to sintering; useful for complex geometries.

- Sintering Shrinkage: Final dimensions may shrink by 15–20%, so pre-machining must account for size reduction.

- Post-Sintering Machining: Only feasible with diamond tools under controlled conditions due to the ceramic’s hardness and toughness.

- Handling During Machining: Despite its toughness, sintered MSZ can chip or crack under stress or improper handling.

- Machining Difficulty: Dense MSZ is labor-intensive to grind and requires advanced CNC and diamond tooling setups.

Magnesia Stabilized Zirconia Ceramic Packaging

Magnesia stabilized zirconia ceramic products are typically packaged in vacuum-sealed bags to prevent moisture or contamination and wrapped with foam to cushion vibrations and impacts during transport, ensuring the quality of products in their original condition.

Download

Get A Quote

We will check and get back to you in 24 hours.