Zirconia Toughened Alumina Crucible

Zirconia Toughened Alumina Crucible

Zirconia Toughened Alumina Crucible is made from a durable ceramic composite that blends the hardness of alumina with the enhanced toughness of zirconia. It offers excellent resistance to thermal shock, wear, and chemical corrosion, making it suitable for high-temperature and aggressive environments. Available in a variety of shapes—including Cylinder, Conical Cylinder, Rectangular, T-shape—or fully customized designs, these crucibles are built to handle demanding laboratory and industrial processes. We can supply high-quality zirconia toughened alumina crucibles with various specifications and competitive prices, offering customized solutions to meet specific requirements.

Or email us at sales@heegermaterials.com.Zirconia Toughened Alumina Crucible Data Sheet

| Composition: | Alumina/Zirconia |

| Color: | White or off white |

| Dimensions: | Customized |

| shape: | Cylinder, Conical Cylinder, Rectangular, T-shape, or customized. |

Zirconia Toughened Alumina Crucible Description

Zirconia toughened alumina crucible is a high-performance ceramic vessel designed for use in harsh thermal and chemical environments. By combining zirconia’s crack resistance with alumina’s strength, it offers excellent durability under repeated heating and cooling cycles. These crucibles come in various shapes, such as cylindrical, conical, rectangular, T-shaped, or can be fully customized to fit unique setups. They are well-suited for applications like metal melting, powder calcination, and materials testing.

- Rectangle Zirconia Toughened Alumina Crucible

- Cylindrical Zirconia Toughened Alumina Crucible

Zirconia Toughened Alumina Crucible Specifications

| Shape | Capacity (ml) | Max Outer Diameter (mm) | Approx. Inner Diameter (mm) | Length (mm) | Width (mm) | Height (mm) |

| Cylindrical | 830 | 98 | 90 | — | — | 128 |

| Cylindrical | 1450 | 112 | 103 | — | — | 190 |

| Conical | 700 | 96 | 90 | — | — | 145 |

| Rectangular | 450 | — | — | 208 | 111 | 25 |

| Note | Size and shape can be customized based on specific requirements | |||||

Zirconia Toughened Alumina Crucible Features

- Enhanced Toughness: Zirconia content improves resistance to cracking and thermal shock.

- High-Temperature Stability: Performs reliably in extreme heat conditions up to 1700°C.

- Excellent Wear Resistance: Maintains structural integrity during repeated use in abrasive environments.

- Chemical Inertness: Resists corrosion from acids, alkalis, and molten materials.

- Multiple Shapes Available: Offered in Cylinder, Conical Cylinder, Rectangular, T-shape, or custom designs to fit different setups.

Zirconia Toughened Alumina Crucible Applications

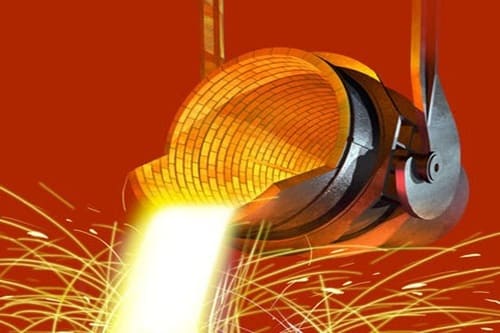

- Metal Melting and Casting: Used for melting high-purity metals and alloys at high temperatures.

- Powder Calcination: Ideal for heat treatment of ceramic powders and advanced materials.

- Material Research: Suitable for high-temperature experiments in laboratories and R&D centers.

- Chemical Analysis: Used in ashing, sample preparation, and reactions involving corrosive chemicals.

- Thermal Processing Equipment: Serves as a durable container in industrial kilns and furnaces.

Zirconia Toughened Alumina Material Properties

Zirconia Toughened Alumina Material Grades

CeramAlloy ZTA is a high performance ceramic composite and a unique ceramic material by way of exhibiting a combination of high hardness, strength, wear and corrosion resistance resulting from its Alumina content, while still maintaining reasonably high fracture toughness resulting from its Zirconia content.

Applications:

- High pressure equipment – ball valve balls and seats

- Rollers and guides for metal forming

- Thread and wire guides

- Deep well down-hole valves and seats

- Shaft bearings/bushings

Ultra Hard is a high performance ceramic composite and a unique ceramic material by way of exhibiting a combination of high hardness, strength, wear and corrosion resistance resulting from its Alumina content, while still maintaining reasonably high fracture toughness resulting from its Zirconia content.

Applications:

- High pressure equipment – ball valve balls and seats – particularly suitable for high flow/abrasive fluids

- Focusing nozzles for abrasive media

- Ultra high pressure pumping elements

- Deep well down-hole valves and seats

- Rollers and guides for metal forming

- Thread and wire guides

- Metal extrusion dies

Zirconia Toughened Alumina Ceramic Machining

Zirconia Toughened Alumina (ZTA) is a high-performance composite material that enhances toughness and strength by incorporating zirconia (ZrO₂) into alumina (Al₂O₃). Machining this material requires addressing its high hardness and brittleness. Key machining aspects include:

- Cutting: Utilizes diamond tools or laser cutting for precision and edge integrity.

- Grinding: Employs precision grinding to control surface roughness and dimensional tolerances.

- Drilling: Uses ultrasonic or diamond drills for micro-holes, ideal for electronic applications.

- Surface Finishing: Polishing or coating improves wear resistance and aesthetics.

ZTA machining is widely applied in precision component manufacturing, such as electronic substrates and medical implants.

Zirconia Toughened Alumina Ceramic Packaging

Zirconia Toughened Alumina Ceramic products are typically packaged in vacuum-sealed bags to prevent moisture or contamination and wrapped with foam to cushion vibrations and impacts during transport, ensuring the quality of products in their original condition.

Download

Get A Quote

We will check and get back to you in 24 hours.