Yttria Stabilized Zirconia Substrate

Yttria Stabilized Zirconia Substrate

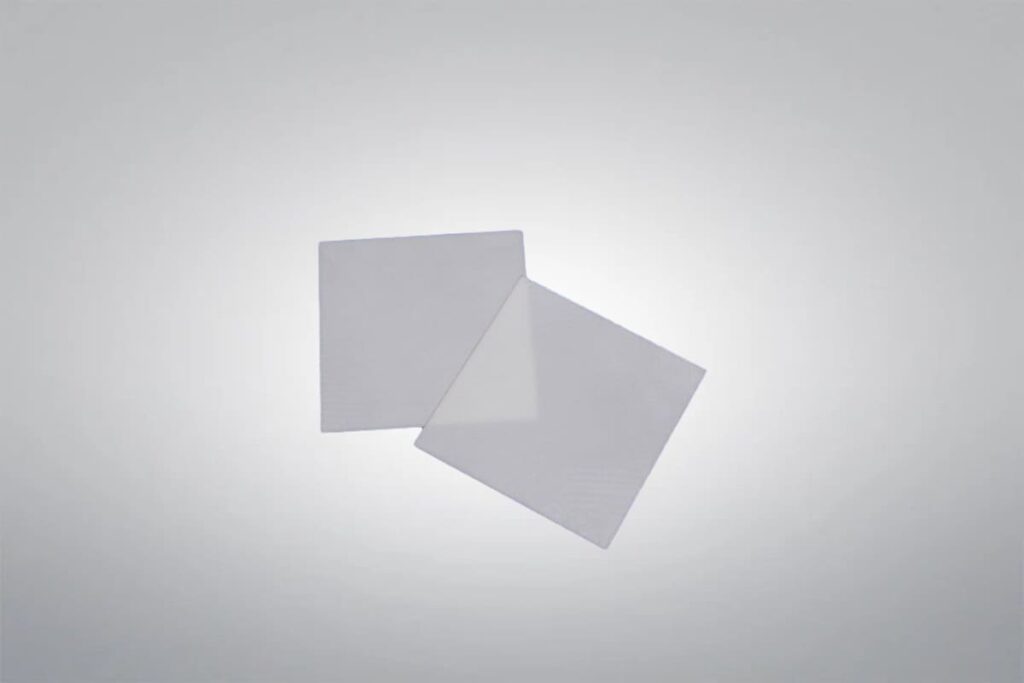

Yttria Stabilized Zirconia Substrate is a high-performance ceramic base material known for its exceptional thermal stability, mechanical strength, and chemical resistance. With a thermal expansion coefficient close to that of steel, it offers excellent compatibility for bonding with metal components. It features high toughness, bending strength, and wear resistance, along with superior insulation properties. This makes it well-suited for demanding applications such as oxygen sensors, heating elements, ceramic knives, SOFC (solid oxide fuel cell) components, and thermal substrates in high-temperature environments. We can supply high-quality yttria stabilized zirconia substrate with various specifications and competitive prices, offering customized solutions to meet specific requirements.

Or email us at sales@heegermaterials.com.Yttria Stabilized Zirconia Substrate Data Sheet

| Crystal Structure: | Cubic |

| Sintering Temperature: | 2370 °C |

| Color: | White |

| Density: | 5.85-6.10 g/cm3 |

| Dimensions: | Up to 100 × 100 × 1.0 mm (custom sizes available upon request) |

| Thickness: | customized |

| Polishing Options: | Single-sided or double-sided |

Yttria Stabilized Zirconia Substrate Description

Yttria Stabilized Zirconia Substrate is a dense and durable ceramic material widely used in functional ceramics due to its outstanding thermal resistance and mechanical integrity. It exhibits strong flexural strength, high fracture toughness, and excellent wear and insulation performance. With an expansion coefficient closely matching that of steel, YSZ substrates ensure reliable structural stability under thermal cycling. These substrates are commonly produced through advanced methods such as dry pressing, isostatic pressing, slip casting, and tape casting. They are ideal for use in high-temperature heating tubes, refractory layers, ceramic heaters, oxygen sensors, and SOFC-based thermal platforms.

Yttria Stabilized Zirconia Substrate Chemical Compositions

| Composition | Content % |

| ZrO2 | 93.6 |

| MgO | 0.1 |

| CaO | 0.3 |

| Al2O3 | 0.3 |

| TiO2 | 0.1 |

| Fe2O3 | 0.1 |

| SiO2 | 0.3 |

| Y2O3 | 5.2 |

Yttria Stabilized Zirconia Substrate Features

- Excellent Thermal Resistance: Operates stably at high temperatures up to 1000 °C and beyond, maintaining structural integrity under extreme thermal loads.

- High Mechanical Strength: Offers superior flexural and compressive strength, making it resistant to mechanical stress and deformation.

- Low Thermal Conductivity: Acts as an effective insulator, minimizing heat loss in high-temperature environments.

- Chemical Stability: Resists corrosion from acids, alkalis, and molten metals, making it suitable for harsh chemical processes.

- Matched Thermal Expansion: Thermal expansion coefficient closely aligns with metals like steel, reducing stress in bonded assemblies.

Yttria Stabilized Zirconia Substrate Applications

- Solid Oxide Fuel Cells (SOFC): Used as electrolyte substrates or structural layers due to ionic conductivity and thermal stability.

- High-Temperature Heaters: Acts as a durable platform for heating elements in furnaces and reactors.

- Oxygen Sensors: Enables accurate oxygen detection in automotive and industrial applications.

- Semiconductor Wafer Supports: Provides stable, non-reactive backing during high-precision thermal processing.

- Thermal Barrier Components: Serves as insulating layers in aerospace and energy systems requiring extreme heat resistance.

Yttria Stabilized Zirconia Ceramic Properties

Yttria Stabilized Zirconia Ceramic Material Machining

Yttria Stabilized Zirconia (YSZ) is a high-performance ceramic material known for its exceptional fracture toughness, high strength, and ionic conductivity. These characteristics make it ideal for demanding environments, though its machining requires specialized approaches due to its hardness and brittleness. Key machining aspects include:

- Cutting: Diamond-coated tools or precision laser cutting are employed to maintain edge integrity and minimize microcracking.

- Grinding: Fine-grit diamond grinding is used to achieve tight tolerances and smooth surfaces, especially for components with complex geometries.

- Drilling: Ultrasonic machining or precision diamond drilling enables accurate formation of micro-features for sensor and fuel cell applications.

- Surface Finishing: Polishing enhances wear resistance, biocompatibility, and thermal stability, making it suitable for advanced engineering uses.

Yttria Stabilized Zirconia Ceramic Packaging

Yttria stabilized zirconia ceramic products are typically packaged in vacuum-sealed bags to prevent moisture or contamination and wrapped with foam to cushion vibrations and impacts during transport, ensuring the quality of products in their original condition.

Download

Get A Quote

We will check and get back to you in 24 hours.