Yttria Stabilized Zirconia Grinding Media

Yttria Stabilized Zirconia Grinding Media

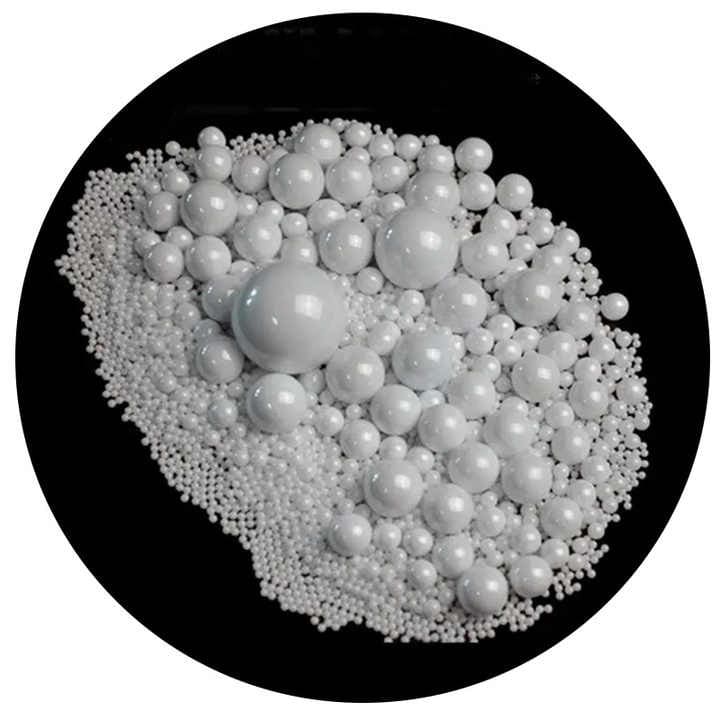

Yttria Stabilized Zirconia Grinding Media are high-performance zirconia beads made using yttrium oxide as a stabilizer and processed through advanced titration, shaping, and sintering techniques. These media feature a uniform microstructure with tetragonal zirconia crystals smaller than 0.5 μm, delivering outstanding wear resistance, corrosion resistance, and mechanical durability. We can supply high-quality yttria stabilized zirconia grinding media with various specifications and competitive prices, offering customized solutions to meet specific requirements.

Or email us at sales@heegermaterials.com.Yttria Stabilized Zirconia Grinding Media Data Sheet

| Color: | White |

| Precision: | 0.001 mm |

| Manufacturing Process: | Sintering Method |

Yttria Stabilized Zirconia Grinding Media Description

Yttria Stabilized Zirconia Grinding Media are precision-engineered ceramic beads made using rare-earth yttrium oxide as a stabilizer through advanced titration rolling and mid-temperature sintering technology. The dense internal structure features ultra-fine tetragonal zirconia crystals under 0.4 μm, giving the media superior corrosion resistance, exceptional wear performance, and high mechanical strength. With perfectly spherical geometry and tightly controlled particle size distribution, these beads deliver stable, contamination-free performance for demanding nano-dispersion and fine grinding processes. Ideal for use in pin-type and turbine-type bead mills, they support ultrafine processing across industries such as digital inks, lithium battery materials, electronic pastes, pharmaceuticals, and high-purity cosmetics.

Yttria Stabilized Zirconia Grinding Media Specifications

| Property | Specification |

|---|---|

| Main Composition | ZrO₂: 94.6% Y₂O₃: 5.2% |

| True Density | 6.0 g/cm³ |

| Bulk Density | 3.8 g/cm³ |

| Mohs Hardness | 9 |

| Wear Rate | <20 ppm/hr (24 hours) |

| Compressive Strength | >2000 kN (Φ2.0 mm) |

| Diameter Range | 0.1–0.2 mm, 0.2–0.3 mm, 0.3–0.4 mm, 0.4–0.6 mm, 0.6–0.8 mm, 0.8–1.0 mm, 1.0–1.2 mm,<br>1.2–1.4 mm, 1.4–1.6 mm, 1.6–1.8 mm, 1.8–2.0 mm, 2.0–2.2 mm, 2.2–2.4 mm, 2.4–2.6 mm,<br>2.6–2.8 mm, 2.8–3.0 mm, 3.0–3.5 mm, 3.5–4.0 mm, 4.0–4.5 mm, 4.5–5.0 mm, 5.0–5.5 mm,<br>5.5–6.0 mm, 6.0–6.5 mm, 6.5–7.0 mm, 8mm, 10mm, 12mm, 15mm, 20mm, or customized |

Yttria Stabilized Zirconia Grinding Media Features

- Excellent Roundness and Surface Finish: Each bead features high sphericity and a smooth, pearl-like luster, ensuring consistent rolling and minimal wear on equipment.

- Superior Toughness and Impact Resistance: With exceptional mechanical strength and resilience, the beads remain intact even under high-speed operation without cracking or breaking.

- Outstanding Wear Resistance: Yttria Stabilized Zirconia Grinding Media offers wear resistance 30–50 times greater than standard glass beads, significantly reducing media consumption and improving longevity.

- High Density for Enhanced Grinding Efficiency: The higher density increases energy transfer during milling, allowing for faster particle size reduction and supporting higher solid content or flow rates.

- Chemical Stability and Purity Protection: Highly resistant to corrosion and suitable for nano-level grinding and dispersion; the media maintains product purity without leaching heavy metals, ideal for pharmaceutical and fine chemical applications.

Yttria Stabilized Zirconia Grinding Media Applications

- Electronic Ceramics and Magnetic Materials: Used in the fine grinding of ferrite, dielectric materials, and magnetic powders for electronic components due to their purity and low contamination.

- Nanomaterials and Battery Powders: Ideal for dispersing and grinding nano-sized lithium compounds and conductive additives in battery and energy storage industries.

- Paints, Inks, and Pigments: Delivers uniform particle size reduction in high-viscosity dispersions such as UV inks, digital printing inks, and automotive coatings.

- Cosmetics, Pharmaceuticals, and Food: Enables ultra-fine grinding of high-purity ingredients while avoiding heavy metal contamination, supporting safety standards in sensitive applications.

- Adhesives, Resins, and Emulsions: Offers efficient milling of polymers, emulsions, and specialty chemicals used in adhesives, coatings, and various chemical formulations.

Yttria Stabilized Zirconia Ceramic Properties

Yttria Stabilized Zirconia Ceramic Material Machining

Yttria Stabilized Zirconia (YSZ) is a high-performance ceramic material known for its exceptional fracture toughness, high strength, and ionic conductivity. These characteristics make it ideal for demanding environments, though its machining requires specialized approaches due to its hardness and brittleness. Key machining aspects include:

- Cutting: Diamond-coated tools or precision laser cutting are employed to maintain edge integrity and minimize microcracking.

- Grinding: Fine-grit diamond grinding is used to achieve tight tolerances and smooth surfaces, especially for components with complex geometries.

- Drilling: Ultrasonic machining or precision diamond drilling enables accurate formation of micro-features for sensor and fuel cell applications.

- Surface Finishing: Polishing enhances wear resistance, biocompatibility, and thermal stability, making it suitable for advanced engineering uses.

Yttria Stabilized Zirconia Ceramic Packaging

Yttria stabilized zirconia ceramic products are typically packaged in vacuum-sealed bags to prevent moisture or contamination and wrapped with foam to cushion vibrations and impacts during transport, ensuring the quality of products in their original condition.

Download

Get A Quote

We will check and get back to you in 24 hours.