Silicon Carbide Spherical Powder

Silicon Carbide Spherical Powder

Purity: >99%, 98%-99%, 95%-98%, or customized

Particle Size: 15-53 μm, 45-105 μm, 75-150 μm, or customized

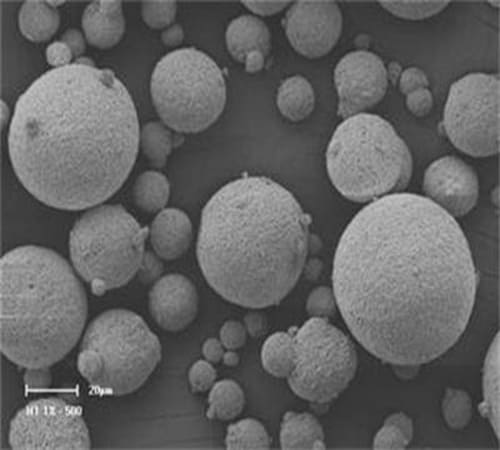

Silicon Carbide Spherical Powder is made of high-purity submicron silicon carbide powder as raw material, with binder added, and through spray granulation technology. As a leading supplier and manufacturer of premium silicon carbide products, we can supply high-quality silicon carbide spherical powders with various specifications and competitive prices, offering customized solutions to meet specific requirements.

Or email us at sales@heegermaterials.com.Silicon Carbide Spherical Powder Data Sheet

| Reference Code: | SP-2044 |

| CAS: | 409-21-2 |

| Purity: | >99%, 98%-99%, 95%-98%, depending on application requirements. |

| Particle Size: | 15-53 μm, 45-105 μm, 75-150 μm, or customized |

| Density: | 3.2 g/cm3 |

| Color: | Black or Green |

| Standard: | ASTM D7573, ISO 9286 |

Silicon Carbide Spherical Powder Description

Silicon Carbide Spherical Powder is made of high-purity silicon carbide powder through the spray granulation method, featuring uniform particle size distributions, good flowability, high strength, high hardness, wear resistance, corrosion resistance, and good thermal conductivity. It is widely applied in additive manufacturing, thermal management, and advanced coatings. Advanced Ceramics Hub can supply high-quality silicon carbide spherical powder with various purity grades and particle sizes for diverse industry and research applications.

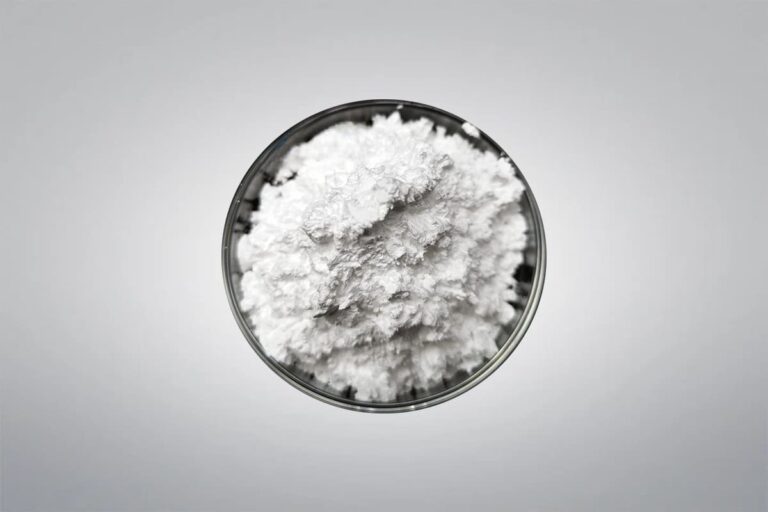

Silicon Carbide Spherical Powder Silicon Carbide Spherical Powder SEM

Silicon Carbide Powder Solutions

Silicon Carbide Spherical Powder

Silicon Carbide (SiC) Spherical Powder features excellent flowability and uniform particle size distribution, making it widely used in additive manufacturing, thermal management, advanced coatings, and other demanding applications.

Silicon Carbide Spherical Powder Chemical Composition

| Chemical Composition | Value |

| Silicon carbide (SiC) | ≥ 99.0% |

| Free Carbon (F.C) | ≤1.0% |

| Free Silicon (F.Si) | ≤0.2% |

| Ferro (Fe2O3) | ≤0.1% |

| Boron (B) | 0.65-1.3% |

Silicon Carbide Spherical Powder Types

| Grade Type | Application |

|---|---|

| High-Purity Grades | Designed for semiconductor and electronics industries. |

| Standard Grades | Used in abrasives, ceramics, and coatings. |

| Nano-Sized Powders | Designed for the semiconductor and electronics industries. |

Silicon Carbide Spherical Powder Features

- Excellent flowability

- Uniform particle size distribution

- High bulk density

- Good thermal conductivity

- High-temperature stability

- Oxidation and corrosion resistance

Silicon Carbide Spherical Powder Applications

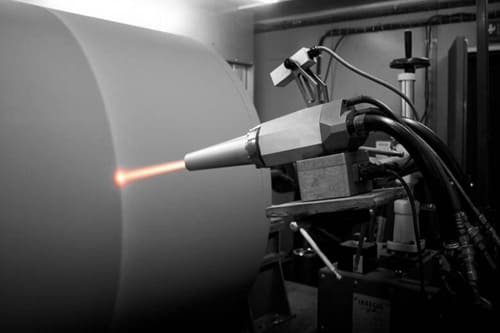

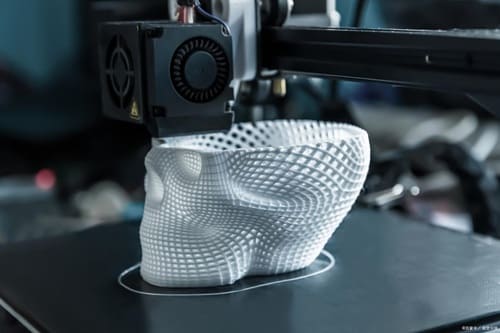

- Additive Manufacturing (3D Printing): Due to its excellent flowability and uniform particle distribution, spherical silicon carbide powder is commonly used in additive manufacturing, especially for producing high-strength and wear-resistant parts.

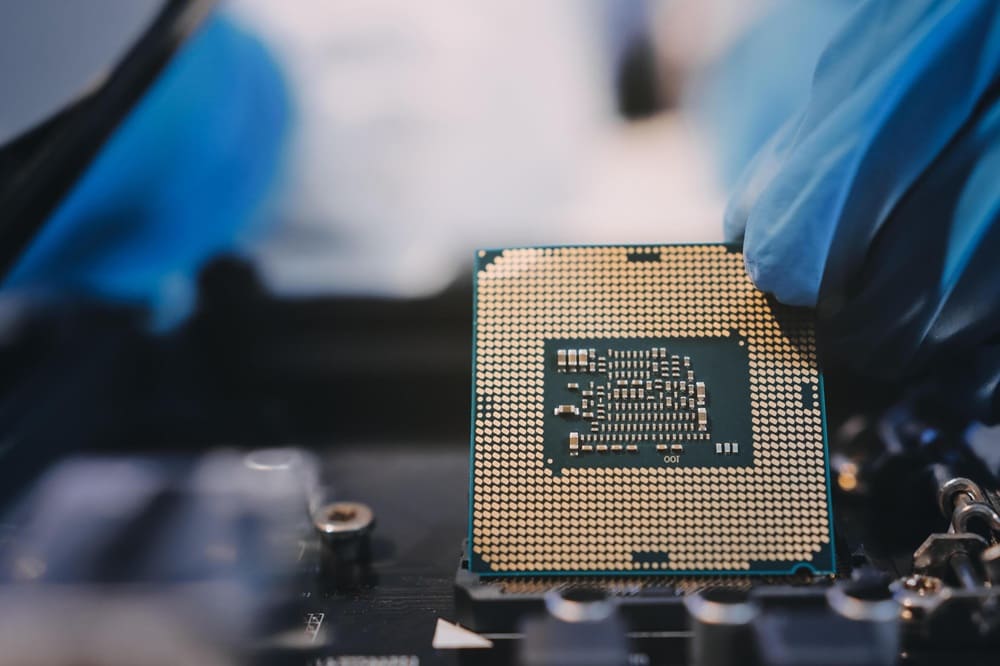

- Thermal Management: With its excellent thermal conductivity, spherical silicon carbide powder is widely used in thermal management systems for electronic devices, such as heat sinks and thermal conductive materials, helping to enhance the thermal stability and prolong the lifespan of the equipment.

- Advanced Coatings: Spherical silicon carbide powder is often used in producing high-performance coatings, such as wear-resistant coatings and corrosion-resistant coatings, to improve surface durability and resistance to wear.

- Semiconductor and Electronics Applications: The high thermal conductivity and good electrical conductivity of silicon carbide make it widely used in high-tech fields such as semiconductors, LEDs, and solar cells.

- Composite Materials: Spherical silicon carbide powder is commonly used to reinforce composite materials, enhancing their mechanical properties and high-temperature resistance, with applications in industries like aerospace and automotive.

- Abrasives and Polishing: Due to the high hardness of silicon carbide, it is used in precision polishing, grinding, and other processes.

Silicon Carbide Spherical Powder Packaging

The Silicon Carbide Spherical Powder is carefully placed in wooden cases or cartons with additional support from soft materials to prevent any shifting during transportation. This packaging method guarantees the integrity of the products throughout the delivery process.

Download

Get A Quote

We will check and get back to you in 24 hours.