Silicon Carbide Powder

Silicon Carbide Powder

Purity: 95%-99%

Particle Size: 325 mesh, or customized

Silicon Carbide Powder is a high-performance inorganic non-metallic material with exceptional hardness, high-temperature resistance, and chemical stability. It is widely used as an abrasive for precision machining and coating materials in various industries. As a leading supplier and manufacturer of premium silicon carbide products, we can supply high-quality silicon carbide powders with various specifications and competitive prices, offering customized solutions to meet specific requirements.

Or email us at sales@heegermaterials.com.Silicon Carbide Powder Data Sheet

| Reference Code: | HMCP-1701 |

| CAS: | 409-21-2 |

| Purity: | 95%-99% |

| Particle Size: | 325 mesh, or customized |

| Density: | 3.2 g/cm3 |

| Color: | Black or Green |

Silicon Carbide Powder Description

Silicon Carbide Powder has a hexagonal crystal structure and is typically available in two main types: black silicon carbide and green silicon carbide. Both belong to α-SiC. Black silicon carbide contains about 98.5% SiC and has higher toughness than green silicon carbide, which is primarily used for processing materials with lower tensile strength. Green silicon carbide contains more than 99% SiC and has excellent self-shaping properties, mainly used for processing hard alloys, titanium alloys, and optical glass. Advanced Ceramics Hub can supply high-quality silicon carbide powder with various purities and particle sizes for diverse industry and research applications.

Silicon Carbide Powder_500 mesh Silicon Carbide Powder_200 mesh Silicon Carbide Powder_100 mesh Silicon Carbide Powder_1μm

Silicon Carbide Powder Solutions

Silicon Carbide Powder Features

- The particle distribution is concentrated and uniform, with no large particles.

- The product contains minimal impurities and has high purity.

- Customization is available according to specific requirements.

Silicon Carbide Powder Applications

- Abrasives & Polishing: For sandpaper, grinding wheels, and polishing compounds to process metals, glass, and ceramics.

- Refractories: As an additive in high-temperature kilns and steelmaking furnaces to enhance heat/corrosion resistance.

- Ceramic Reinforcement: Mixed with structural ceramics (e.g., Al₂O₃, ZrO₂) to improve toughness, wear resistance, and thermal conductivity.

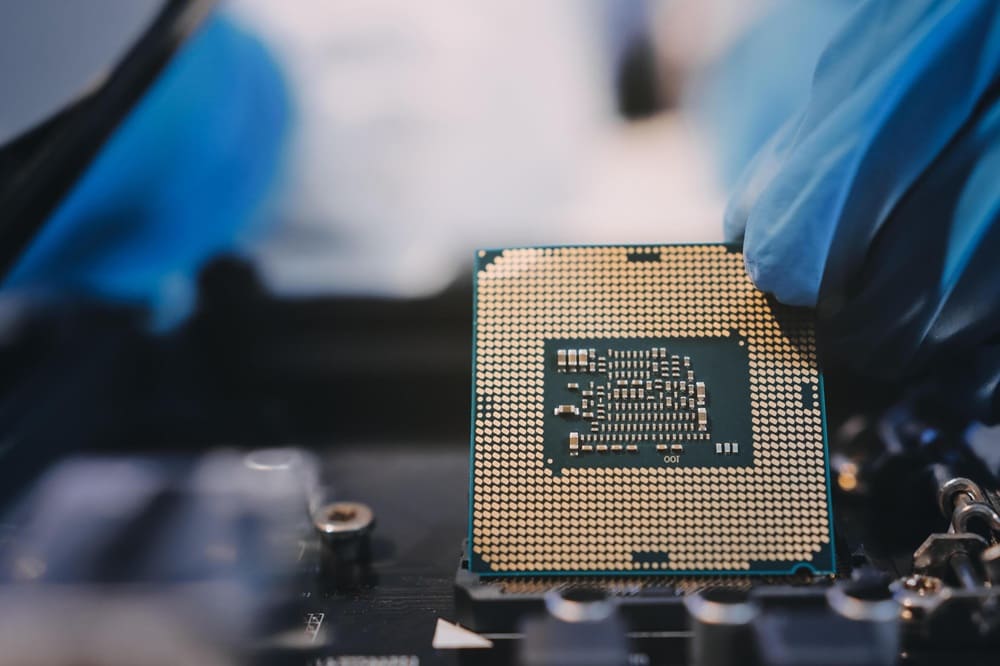

- Semiconductors & Electronics: High-purity SiC powder for wafer substrates, power devices, and RF components.

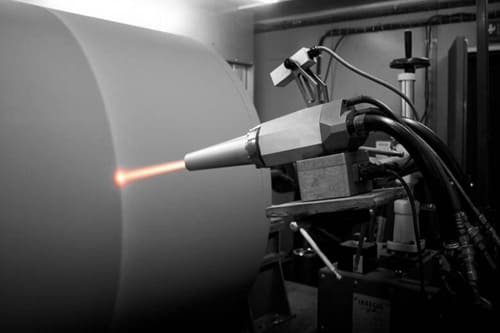

- Coatings: Applied via thermal spray or PVD to protect tools and aerospace components from wear.

- Composites: Combined with metals/polymers for brake pads, armor plates, and high-performance parts.

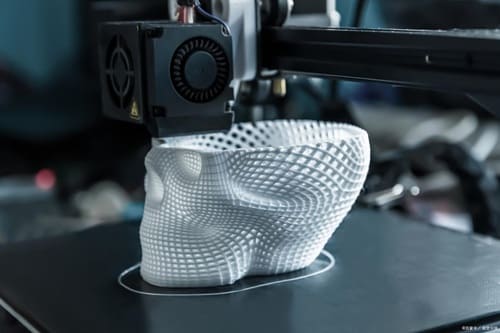

- 3D Printing: As a high-strength, heat-resistant material for additive manufacturing.

- Solar Energy: Used in polysilicon ingot furnace linings and coatings.

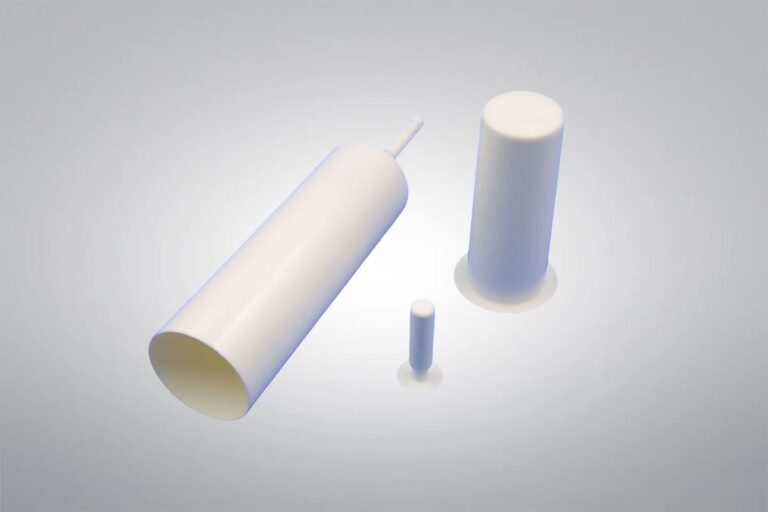

Silicon Carbide Powder Packaging

The Silicon Carbide Powder is carefully placed in wooden cases or cartons with additional support from soft materials to prevent any shifting during transportation. This packaging method guarantees the integrity of the products throughout the delivery process.

Download

Get A Quote

We will check and get back to you in 24 hours.