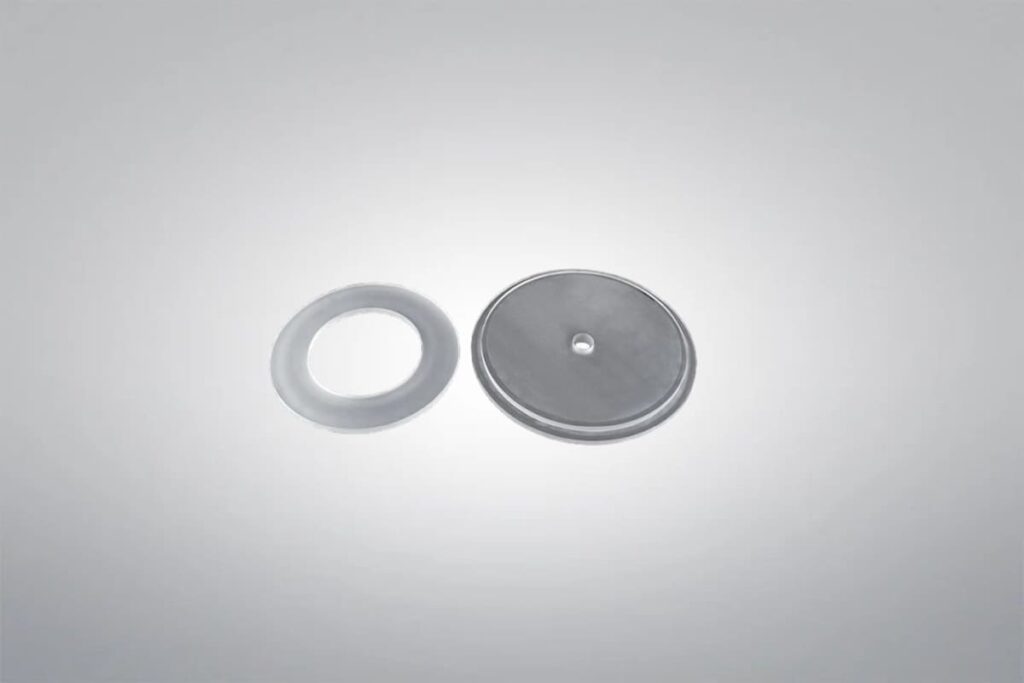

Quartz Window

Quartz Window

Quartz window is a high-performance ceramic component known for its outstanding optical clarity and resistance to thermal and chemical stress. Made from high-purity quartz ceramic, it can operate reliably in harsh environments such as vacuum systems, semiconductor equipment, and high-intensity light sources. Its ability to maintain transparency and structural integrity under extreme conditions makes it suitable for demanding optical and protective applications. We can supply high-quality quartz window for etching equipment with various specifications and competitive prices, offering customized solutions to meet specific requirements.

Or email us at sales@heegermaterials.com.Quartz Window Data Sheet

| Color: | White – transparent |

| Shape: | Customized |

| Dimension (inch): | Customized |

| Chemical Formula: | SiO2 |

Quartz Window Description

Quartz window is a ceramic-based optical part designed to endure extreme thermal and chemical environments while maintaining excellent light transmission properties. Unlike conventional glass, quartz ceramic offers superior hardness, thermal shock resistance, and minimal distortion under high temperatures. It is commonly used in high-temperature observation ports, plasma chambers, and optical analysis systems where both durability and optical clarity are essential.

Quartz Window Features

- Excellent Thermal Stability: Withstands rapid temperature changes and high operating temperatures.

- High Optical Clarity: Transmits UV, visible, and IR light with minimal distortion.

- Chemical Resistance: Resists most acids and corrosive environments.

- Durability: Maintains structural integrity under mechanical stress and harsh environments.

- Low Thermal Expansion: Reduces the risk of cracking during temperature cycling.

Quartz Window Applications

- Semiconductor Processing: Used as viewports and protective covers in etching and deposition chambers.

- Laser Systems: Serves as optical windows in high-energy laser equipment.

- Vacuum Equipment: Acts as a barrier that maintains vacuum while allowing optical access.

- Analytical Instruments: Applied in spectrometers and microscopes for light transmission.

- Furnace Observation Ports: Enables safe viewing of internal furnace conditions.

Quartz Ceramic Material Properties

| Purity (%) | >99.8 | >99.5 |

| Density (g/cm3) | 1.9-1.95 | 1.9-1.95 |

| Flexture strength (MPa) | 28 | 28 |

| Compressive strength (MPa) | >50 | >50 |

| Bending strength (MPa) | 25 | 25 |

| Maximum working temperature (℃) | 1650 | 1650 |

| Thermal conductivity (W/m*K) | <1 | <1 |

| Thermal expansion coefficient (/℃) | 8.5*10-7 | 8.5*10-7 |

| number of use | ≥10 | ≥10 |

Quartz Ceramic Material Machining

Quartz ceramic material can be machined in its green or bisque state before sintering, making it easier to shape into complex forms. Like other ceramics, it shrinks by about 15–20% during sintering, so this must be considered in the initial design. After sintering, quartz ceramic becomes extremely hard and brittle, making machining very difficult and requiring diamond-coated tools and high-precision equipment.

Machining Methods and Considerations

- Green or Bisque Machining: Quartz ceramic is easier to cut and shape before sintering, making it suitable for intricate designs.

- Sintering Shrinkage: Expect a 15–20% size reduction during sintering, which affects dimensional accuracy.

- Post-Sintering Machining: After sintering, quartz becomes hard and brittle, requiring diamond tools and precise control.

- Fragility: Fully sintered quartz ceramic is prone to chipping or cracking if mishandled.

- Tooling and Time: Machining sintered quartz is slow and requires specialized equipment.

Quartz Ceramic Packaging

Quartz ceramic products are typically packaged in vacuum-sealed bags to prevent moisture or contamination and wrapped with foam to cushion vibrations and impacts during transport, ensuring the quality of products in their original condition.

Download

Get A Quote

We will check and get back to you in 24 hours.