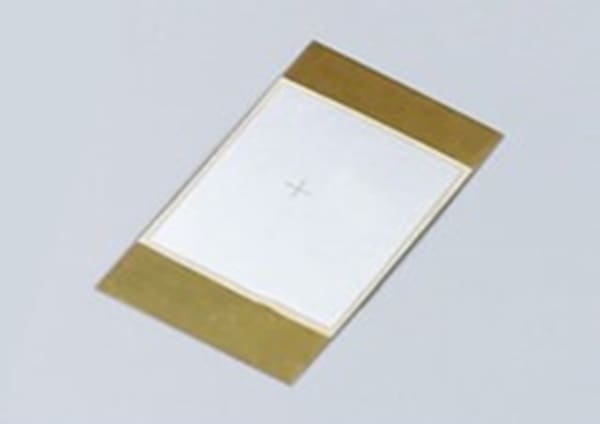

PZT Substrate

PZT Substrate

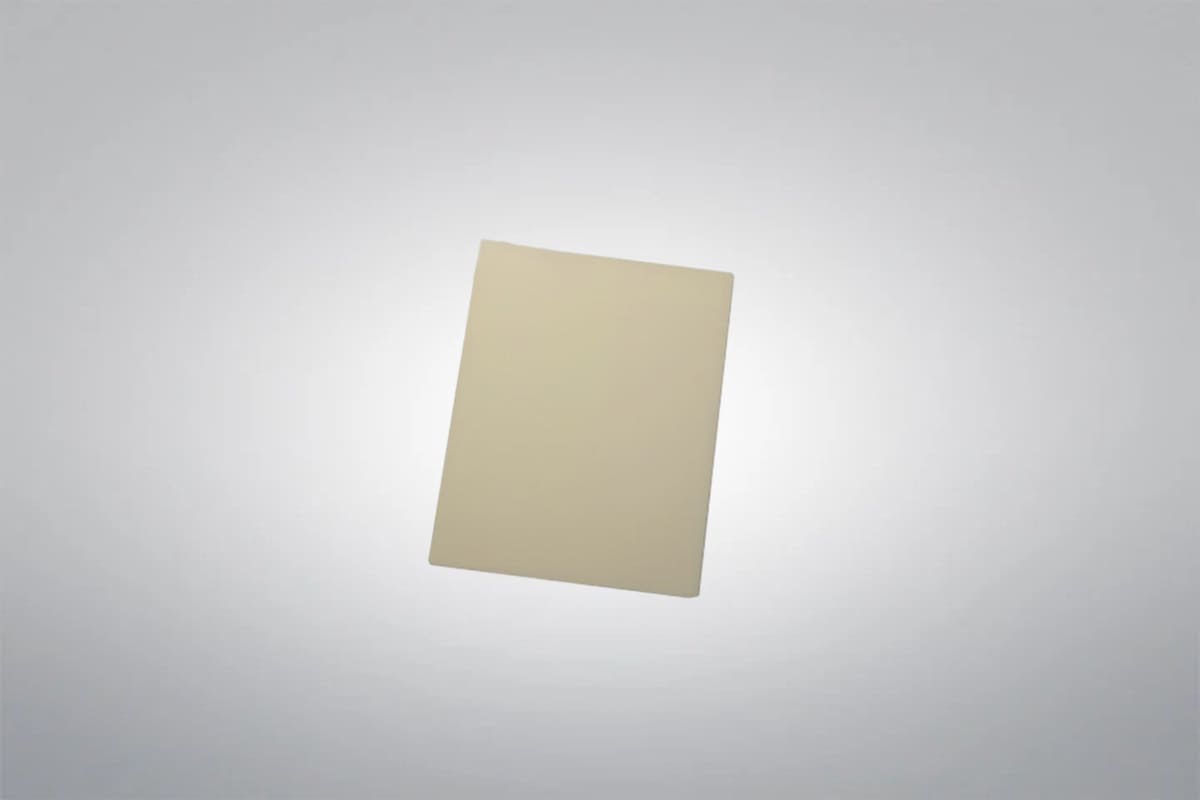

PZT substrate is made from high-performance lead zirconate titanate ceramic, offering strong electromechanical coupling, a high dielectric constant, and stable performance. It is widely used in medical imaging, precision positioning, and industrial sensing, ensuring reliable operation and long service life. We can supply high-quality PZT Substrate with various specifications and competitive prices, offering customized solutions to meet specific requirements.

Or email us at sales@heegermaterials.com.PZT Substrate Data Sheet

| Material: | Lead Zirconate Titanate (PZT) |

| Shape: | Substrate |

| Dimension: | Standard or customized |

| Density: | 7.6-7.9g/cm3 |

PZT Substrate Description

PZT substrate is a piezoelectric ceramic base material made from lead zirconate titanate, offering excellent piezoelectric response, dielectric properties, and mechanical strength. It provides a stable platform for sensors, actuators, ultrasonic transducers, and other precision devices where electrical-to-mechanical energy conversion is required. With precise dimensional control and good thermal stability, the PZT substrate ensures consistent performance across various operating conditions.

PZT Substrate Specifications

| Parameter | Specification |

|---|---|

| Max Size | 120 × 90 mm |

| Min Size | 30 × 30 mm |

| Thickness | 0.1 – 9.0 mm |

| Customized Size | Available on request |

PZT Substrate Features

- High Piezoelectric Performance: Delivers strong electromechanical coupling for efficient energy conversion in sensing, actuation, and ultrasonic applications.

- Excellent Dielectric Properties: Maintains a stable dielectric constant and low loss across a wide frequency range.

- Precision Dimensional Control: Manufactured with tight tolerances to ensure uniform thickness and consistent performance.

- Wide Size and Thickness Range: Available in various sizes and thicknesses to meet different application requirements.

- Custom Fabrication Options: Can be customized in size, shape, and metallization patterns for specific device designs.

PZT Substrate Applications

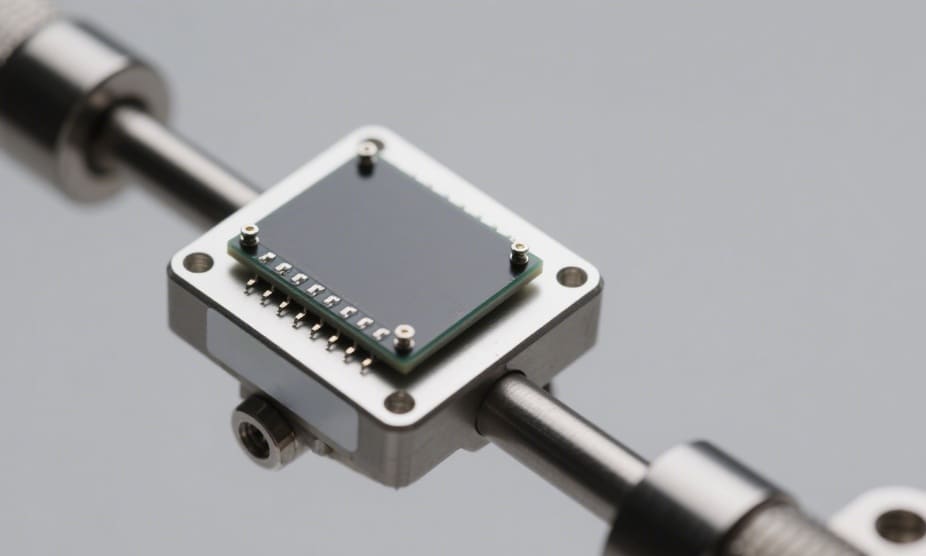

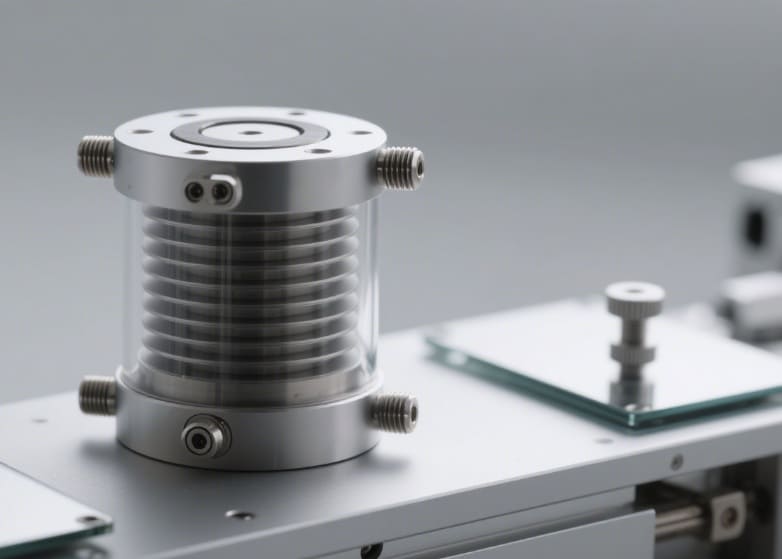

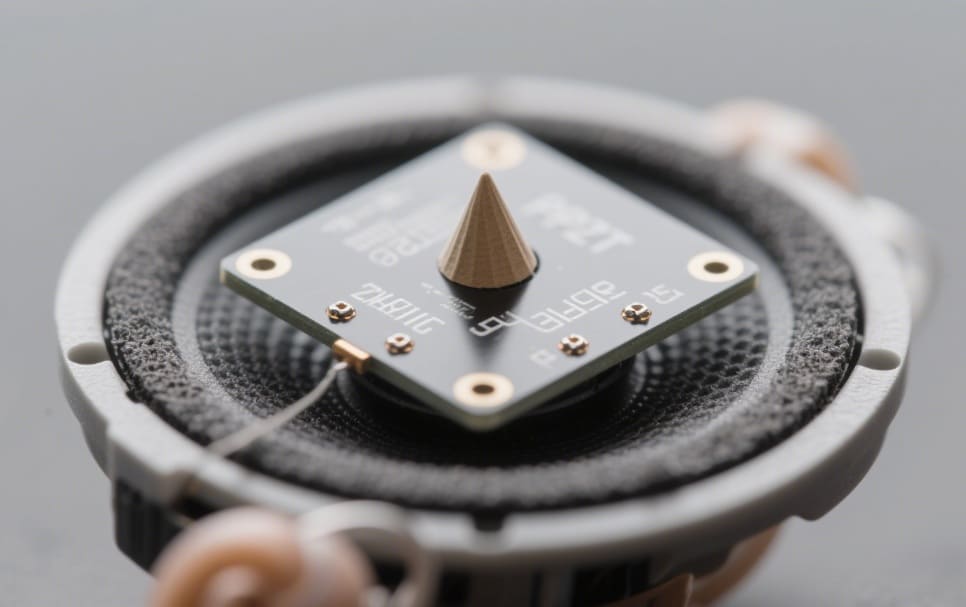

- Ultrasonic Transducers: Serve as the active layer in medical imaging, industrial flaw detection, and underwater sonar systems.

- Sensors: Used in pressure, vibration, and acceleration sensing devices for industrial and automotive applications.

- Actuators: Powers micro-positioning stages, precision motion systems, and adaptive optics mechanisms.

- Energy Harvesting Devices: Convert mechanical vibrations into electrical energy for low-power electronics.

- Microelectromechanical Systems (MEMS): Forms the piezoelectric base for MEMS devices in communications, defense, and instrumentation.

PZT Ceramic Material Properties

| Properties | Materials | |||||||||||

| PZT4 | PZT5 | PZT8 | ||||||||||

| 840 | 841 | 842** | 844** | 850 | 851** | 854 | 855 | 860 | 880 | 881** | ||

| Relative Permittivity | KT | 1275 | 1375 | 1375 | 1500 | 1900 | 1950 | 2750 | 3300 | 1200 | 1050 | 1030 |

| Dielectric Loss Factor (%) | tan δ | 0.60 | 0.40 | 0.45 | 0.40 | ≤ 2.00 | 1.50 | ≤ 2.00 | ≤ 2.50 | ≤2.00 | 0.40 | 0.40 |

| Curie Temperature (°C) | Tc | 325 | 320 | 325 | 320 | 360 | 360 | 250 | 200 | 360 | 310 | 310 |

| Electromechanical Coupling Coefficient | kp | 0.59 | 0.60 | 0.65 | 0.68 | 0.63 | 0.71 | 0.66 | 0.68 | 0.50 | 0.50 | 0.58 |

| k33 | 0.72 | 0.68 | – | – | 0.72 | – | 0.68 | 0.76 | 0.45 | 0.62 | – | |

| k31 | 0.35 | 0.33 | – | – | 0.36 | – | – | 0.40 | – | 0.30 | – | |

| k15 | 0.70 | 0.67 | – | – | 0.68 | – | – | 0.66 | – | 0.55 | – | |

| kt | – | – | 0.48 | 0.48 | – | 0.51 | – | – | – | – | 0.46 | |

| Piezoelectric Charge Constant (10⁻¹² C/N or 10⁻¹² m/V) | d33 | 290 | 300 | 300 | 300 | 400 | 400 | 600 | 630 | 380 | 215 | 220 |

| -d31 | 125 | 109 | – | – | 175 | – | 260 | 276 | – | 95 | – | |

| d15 | 480 | 450 | – | – | 590 | – | 625 | 720 | – | 330 | – | |

| Piezoelectric Voltage Constant (10⁻³ Vm/N or 10⁻³ m²/C) | g33 | 26.5 | 25.5 | 26.3 | 24.5 | 24.8 | 24.8 | 25.5 | 21.0 | 38.0 | 25.0 | 26.7 |

| -g31 | 11.0 | 10.5 | – | – | 12.4 | – | – | 9.0 | – | 10.0 | – | |

| g15 | 38.0 | 35.0 | – | – | 36.0 | – | – | 27.0 | – | 28.0 | – | |

| Young’s Modulus (10¹⁰ N/m²) | YE11 | 8.0 | 7.6 | 8.0 | 7.6 | 6.3 | 6.3 | 6.0 | 5.9 | – | 9.0 | 9.0 |

| YE33 | 6.8 | 6.3 | 6.8 | 6.3 | 5.4 | 5.4 | 5.2 | 5.1 | – | 7.2 | 7.2 | |

| Frequency Constant (Hz·m or m/s) | NL (Length Direction) | 1524 | 1700 | – | – | 1500 | – | – | 1390 | – | 1725 | – |

| NT (Thickness Direction) | 2005 | 2005 | 2050 | 2050 | 2040 | 2040 | 2000 | 2079 | 1390 | 2110 | 2050 | |

| NP (Planar Direction) | 2130 | 2055 | 2230 | 2250 | 1980 | 2080 | 1972 | 1920 | 1900 | 2120 | 2300 | |

| Density (g/cm³) | ρ | 7.6 | 7.6 | 7.6 | 7.7 | 7.6 | 7.6 | 7.6 | 7.6 | 6.6 | 7.6 | 7.6 |

| Mechanical Quality Factor | Qm | 500 | 1400 | 600 | 1500 | 80 | 80 | 70 | 65 | 50 | 1000 | 1000 |

| Acoustic Impedance (Mrayl) | – | – | – | – | 31.5 | – | – | – | 16.5 | – | – | |

Notes:

- @ 1 kHz, low electric field

- Materials 842, 844, 851, and 881 are stock products provided for reference only and are not available for customization.

PZT Ceramic Tolerances

PZT Material Property Parameter Tolerances:

| Parameter | Standard Tolerance | Optional Stricter Tolerance Available |

|---|---|---|

| Capacitance | ±20% | Yes |

| d33 (Piezo Coefficient) | ±20% | Yes |

| Frequency | ±5% | ±0.5% |

Dimension Tolerances:

| Shape & Dimension | Standard Value Range | Tolerance (±) |

| Disc / Ring / Tube | ||

| Outer Diameter | < 25 mm | 0.25 mm |

| ≥ 25 mm to < 38 mm | 0.38 mm | |

| ≥ 38 mm to < 50 mm | 0.60 mm | |

| ≥ 50 mm | 1.00 mm | |

| Ring / Tube | ||

| Inner Diameter | < 6 mm | 0.25 mm |

| ≥ 6 mm to < 13 mm | 0.38 mm | |

| ≥ 13 mm to < 25 mm | 0.50 mm | |

| ≥ 25 mm | 0.60 mm | |

| Square Plate | ||

| Length or Width | < 13 mm | 0.13 mm |

| ≥ 13 mm to < 25 mm | 0.25 mm | |

| ≥ 25 mm to 38 mm | 0.38 mm | |

| ≥ 38 mm to < 50 mm | 0.60 mm | |

| ≥ 50 mm | 1.00 mm | |

| Thickness | 0.20 mm to < 5.00 mm | 0.025 mm |

| ≥ 5.00 mm | 0.05 mm | |

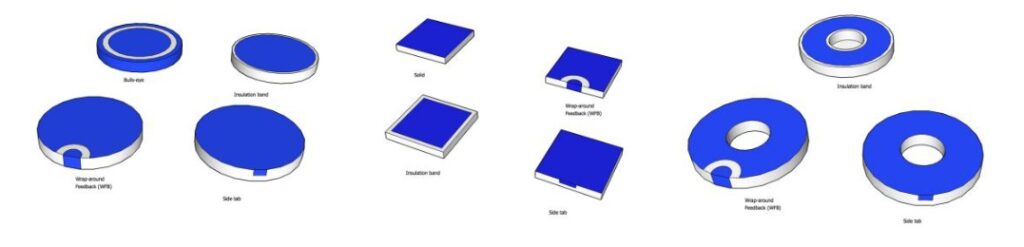

PZT Electrode Specifications

- Standard electrode material: Silver

- Optional electrode materials: Gold, Nickel

- Standard electrode configuration: Solid electrodes covering entire top and bottom surfaces

- Tubular electrode configuration: Electrodes on inner and outer walls (Inner wall: Positive electrode; Outer wall: Negative electrode)

- Custom electrode designs available upon request

| Material | AC Driving Voltage (V/mm) | DC Driving Voltage (V/mm) | Customizable Maximum Voltage (V/mm) |

| PZT4 | 360 ~ 440 | 720 ~ 880 | Up to 1000 |

| PZT5 | 200 ~ 280 | 400 ~ 560 | |

| PZT8 | 360 ~ 440 | 720 ~ 880 |

PZT Ceramic Packaging

PZT ceramic products are typically packaged in vacuum-sealed bags to prevent moisture or contamination and wrapped with foam to cushion vibrations and impacts during transport, ensuring the quality of products in their original condition.

Download

Get A Quote

We will check and get back to you in 24 hours.