PZT Powder

PZT Powder

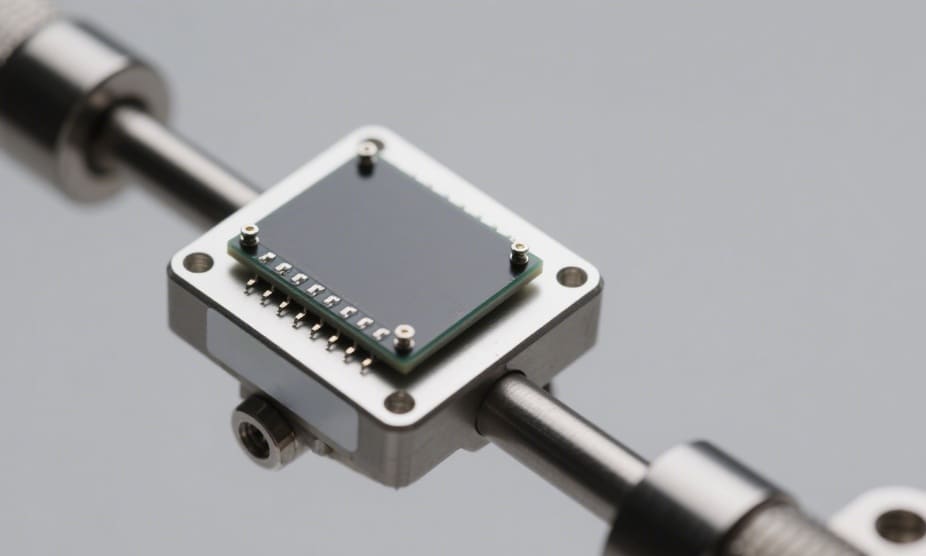

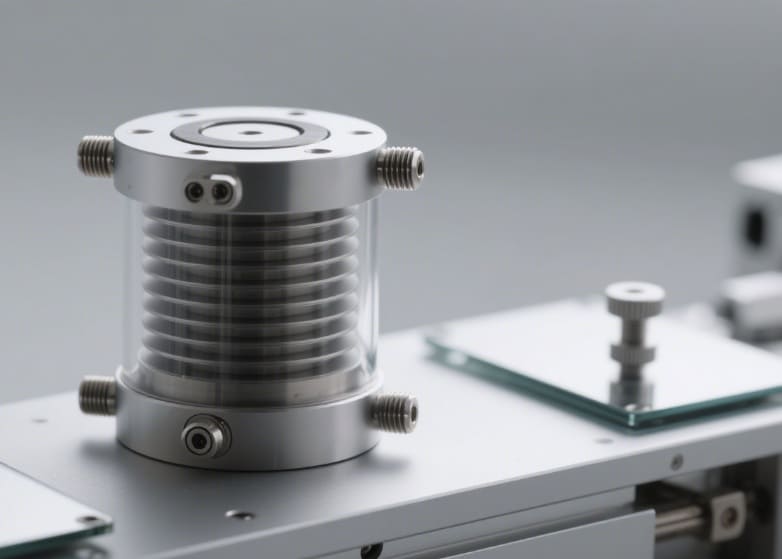

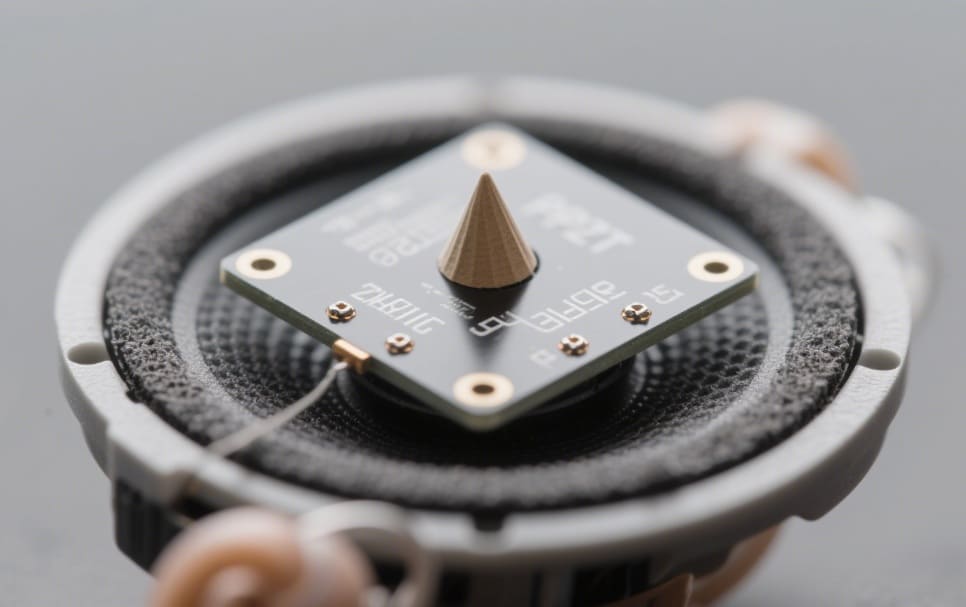

PZT Powder is a high-performance piezoelectric ceramic material designed for both hard and soft piezoelectric applications, offering excellent electromechanical coupling, stability, and tunable properties. Suitable for underwater transducers, sensors, ultrasonic devices, and actuators, it delivers reliable performance for advanced piezoelectric components. We can supply high-quality PZT Powder with various specifications and competitive prices, offering customized solutions to meet specific requirements.

Or email us at sales@heegermaterials.com.PZT Powder Data Sheet

| Material: | Lead Zirconate Titanate (PZT) |

| Color: | White to off-white |

| Particle Size : | Customized |

PZT Powder Description

PZT Powder is a high-performance base material for advanced piezoelectric devices, produced with precise compositional control and microstructural engineering to deliver excellent piezoelectric, dielectric, and stability properties. Based on the lead zirconate titanate (PZT) system, its crystal structure is optimized through phase boundary regulation and doping to ensure high electromechanical coupling and low loss. Hard PZT powders feature dense grain boundaries for enhanced strength and power handling, with models like HMP42, HMP44, and HMP46 offering dielectric constants of 1200–1380 and kp≥0.59. Soft PZT powders improve lattice flexibility via ionic doping, reaching dielectric constants up to 4500, large piezoelectric strain (d33≥680×10⁻¹² C/N), and kt up to 0.78, as in HMP5A, HMP51, and HMP5H. Suitable for underwater transducers, ultrasonic equipment, sensors, and precision actuators, PZT Powder is an ideal choice for high-efficiency, high-performance piezoelectric components.

PZT Powder Technical Specifications

PZT Powder Features

- Customizable Performance: Covers the full spectrum from hard to soft PZT, with gradient parameter design to precisely match device requirements.

- Excellent Process Compatibility: Available in both conventional sintering (≈1260 °C) and low-temperature sintering (down to 985 °C) grades, supporting multilayer monolithic structures and complex device integration.

- Outstanding Piezoelectric & Dielectric Properties: High electromechanical coupling efficiency, stable dielectric constant, and low loss over a wide frequency range.

- High Thermal Stability: Curie temperature (Tc) range of 200–320 °C ensures reliable operation across a wide temperature spectrum.

- High Purity & Quality Assurance: Strict manufacturing and QC standards guarantee consistent particle size, uniform sintering, and reproducible performance.

PZT Powder Applications

- High-Power Ultrasonic Devices (Hard PZT): Suitable for ultrasonic cleaning and atomization transducers (e.g., HMP44), underwater acoustic detection sensors (e.g., HMP42), and high-power welding/emulsification equipment (e.g., HMP8).

- Precision Actuation (Soft PZT): Applied in high-precision piezoelectric actuators (e.g., HMP5H) for optics, positioning, and micro-motion systems.

- High-Sensitivity Sensing: Ideal for hydrophones and sonar receivers (e.g., HMP5A) as well as high-sensitivity receivers (e.g., HMP51) in acoustic measurement systems.

- Energy Conversion & Harvesting: Converts mechanical vibrations into electrical energy for self-powered devices and low-energy wireless sensors.

- RF & Communication Components: Integrated into resonators and filters for stable frequency control in RF and microwave communication equipment.

PZT Powder Packaging

PZT powder is typically packaged in sealed, moisture-proof plastic bags, then placed in sturdy drum containers or fiber cartons to prevent contamination and ensure safe transport. Standard packaging sizes include 1 kg, 5 kg, and 10 kg options, with custom packaging available upon request to meet specific usage or storage needs.

Download

Get A Quote

We will check and get back to you in 24 hours.