Boron Carbide Sputtering Target

Boron Carbide Sputtering Target

Purity: 99.5%

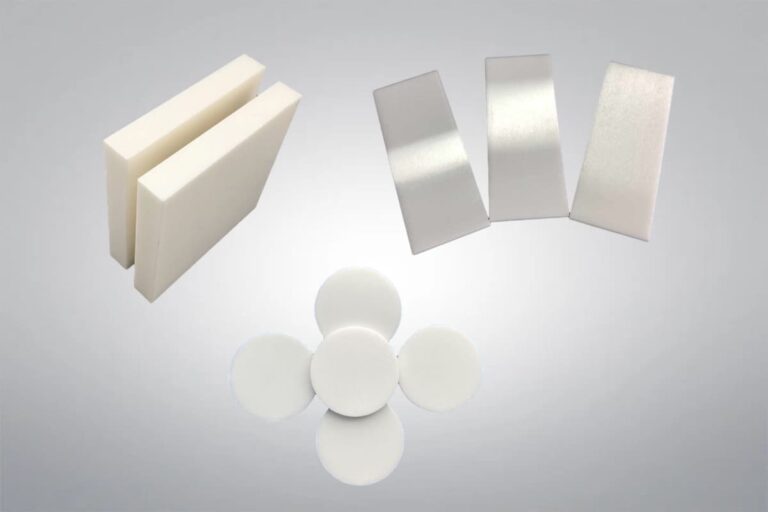

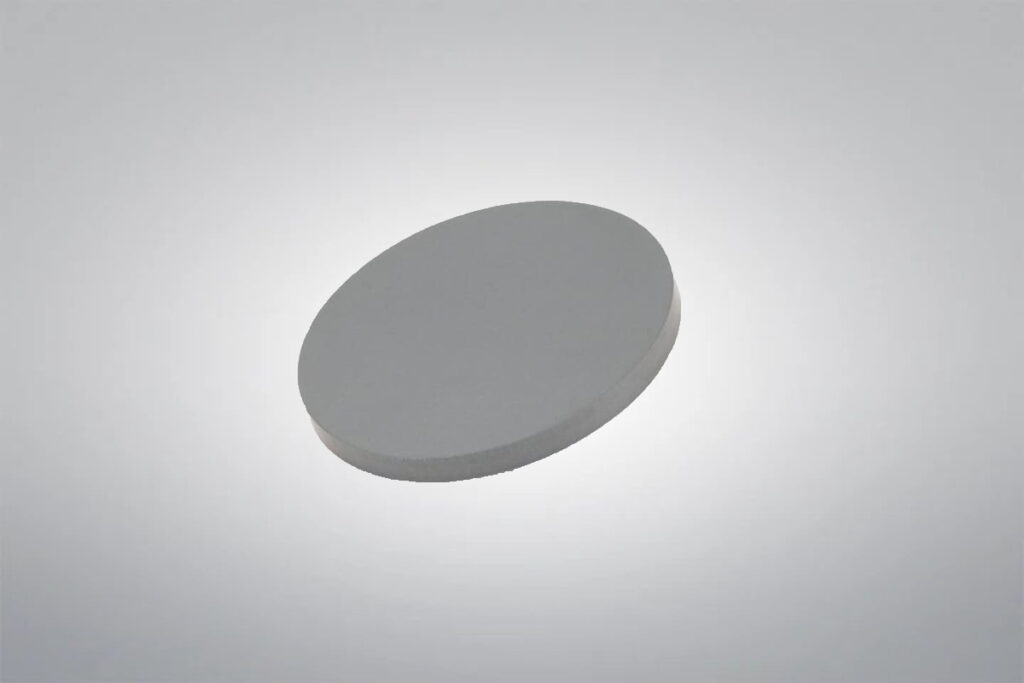

Shape: Rectangular, Disc, Tube

Boron Carbide Sputtering Target (B₄C) is a high-performance material known for its extreme hardness, chemical inertness, and resistance to wear and high temperatures. It is widely used in thin film deposition processes for producing protective coatings, optical films, and semiconductor layers. The target delivers consistent sputtering performance, making it ideal for applications that demand durability and precision in harsh environments. we can supply high-quality Boron Carbide Sputtering Target with various specifications and competitive prices, offering customized solutions to meet specific requirements.

Or email us at sales@heegermaterials.com.Boron Carbide Sputtering Target Data Sheet

| Reference Code: | HTST469 |

| Purity: | 99.5% |

| CAS: | 12069-32-8 |

| Apparence | Black or grey, Crystalline Solid |

| Chemical Formula: | B₄C |

| Molar Mass: | 55.255 g/mol |

| Density: | 2.52 g/cm³ |

| Melting Point: | 2,763 °C (5,005 °F; 3,036 K) |

| Boiling Point: | 3,500 °C (6,330 °F; 3,770 K) |

| shape: | Rectangular, Disc, Tube |

| Bonding Service | Unbonding or Bonding |

Boron Carbide Sputtering Target

Boron Carbide Sputtering Target Powder features high purity and density, delivering reliable performance in thin film applications. Fine, low-particle characteristics ensure uniform film thickness distribution and efficient material utilization during sputtering. This powder is well-suited for producing hard, chemically resistant coatings in advanced optical and electronic devices.

Boron Carbide Sputtering Target Specifications

| Circular Sputtering Targets | Diameter | 1.0”, 2.0”, 3.0”, 4.0”, 5.0”, 6.0” up to 21” |

| Rectangular Sputtering Targets | Width x Length | 5” x 12”, 5” x 15”, 5” x 20”, 5” x 22”, 6” x 20” |

| Thickness | 1.0”, 2.0”, 3.0”, 4.0”, 5.0”, 6.0” up to 21” | |

Boron Carbide Sputtering Target Features

- Extreme Hardness: Provides excellent wear resistance for durable thin film coatings.

- High Purity: Ensures consistent sputtering performance and clean film deposition.

- Thermal Stability: Performs reliably under high-temperature processing conditions.

- Chemical Inertness: Suitable for use in corrosive or reactive environments.

- Uniform Erosion Profile: Supports stable and even film thickness over time.

Boron Carbide Sputtering Target Applications

- Nuclear Radiation Shielding: Used in the fabrication of thin films for neutron-absorbing barriers in nuclear reactors.

- Control Rod Coatings: Applied to create surface layers in control rods, enhancing neutron absorption efficiency.

- Shutdown Pellet Films: Utilized in thin films for emergency shutdown systems in nuclear facilities.

- Protective Optical Coatings: Used in optics where high hardness and radiation resistance are required.

- Semiconductor Components: Suitable for producing hard, chemically stable layers in semiconductor processing.

Boron Carbide Material Properties

Boron Carbide Material Grades

Reaction bonded boron carbide (B4C) is primarily used ballistic armor, providing excellent protection while reducing weight as compared to other armor materials.

| Properties | Units | Reaction Bonded Boron Carbide |

| Flexural Strength, MOR (20 °C) | MPa | 250 |

| Fracture Toughness, KIc | MPa m1/2 | 3.0 – 4.0 |

| Thermal Conductivity (20 °C) | W/m K | 50 |

| Coefficient of Thermal Expansion | 1×10-6/°C | 4.5 |

| Maximum Use Temperature | °C | 1000 |

| Dielectric Strength (6.35mm) | ac-kV/mm | — |

| Dielectric Loss (tan δ) | 1MHz, 25 °C | — |

| Volume Resistivity (25°C) | Ω-cm | 10³ |

Reaction Bonded B4C Advantages:

- High strength

- High hardness

- Cost-effective

- Suitable for large-scale applications

Hot-pressed, also known as pressure assisted densified (PAD), boron carbide is one of the hardest materials available in commercial shapes. This exceptional hardness combined with low density is used in ballistic armor, maximizing protection while minimizing weight.

| Properties | Units | Hot Pressed Boron Carbide |

| Flexural Strength, MOR (20 °C) | MPa | 320 – 450 |

| Fracture Toughness, KIc | MPa m1/2 | 3.0 – 4.0 |

| Thermal Conductivity (20 °C) | W/m K | 45 – 100 |

| Coefficient of Thermal Expansion | 1×10-6/°C | 4.5 – 4.9 |

| Maximum Use Temperature | °C | 2000 |

| Dielectric Strength (6.35mm) | ac-kV/mm | — |

| Dielectric Loss (tan δ) | 1MHz, 25 °C | — |

| Volume Resistivity (25°C) | Ω-cm | 100 |

Hot Pressed B4C Advantages:

- Higher density

- Better mechanical properties

- Ideal for high-strength, high-temperature engineering materials

Pressureless sintered boron carbide combines high purity and the excellent mechanical properties of boron carbide for use in both ballistic armor and semiconductor manufacturing.

| Properties | Units | Sintered Boron Carbide |

| Flexural Strength, MOR (20 °C) | MPa | 450 |

| Fracture Toughness, KIc | MPa m1/2 | 3.0 – 5.0 |

| Thermal Conductivity (20 °C) | W/m K | 43 – 100 |

| Coefficient of Thermal Expansion | 1×10-6/°C | 4.5 – 4.9 |

| Maximum Use Temperature | °C | — |

| Dielectric Strength (6.35mm) | ac-kV/mm | — |

| Dielectric Loss (tan δ) | 1MHz, 25 °C | — |

| Volume Resistivity (25°C) | Ω-cm | 10 |

Pressureless Sintered B4C Advantages:

- High hardness

- Excellent wear resistance

- High chemical stability

- Low density

- Good thermal stability

Boron Carbide Ceramic Machining

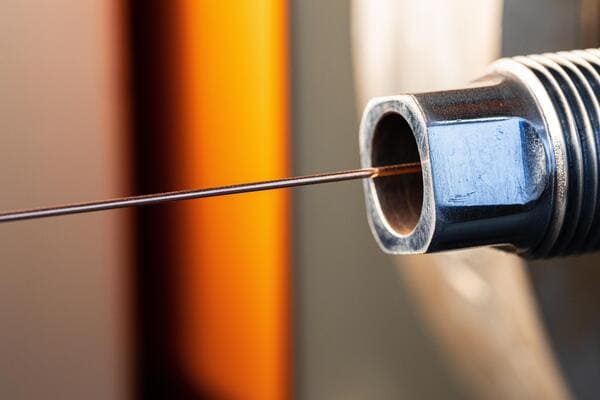

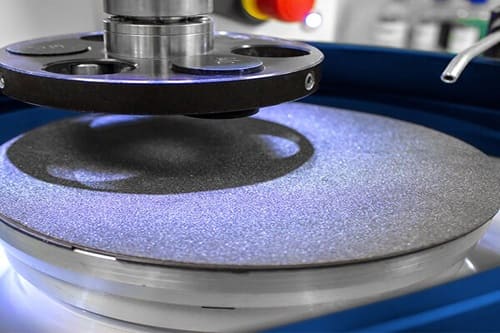

Boron Carbide Ceramic machining is a demanding process used to shape this ultra-hard ceramic into precise components for technical applications. Due to its exceptional hardness and brittleness, machining boron carbide requires specialized tools and careful control to prevent cracking or surface damage. While the material can be shaped more easily in its green or biscuit state, achieving tight tolerances often requires machining after full sintering, which involves diamond-based techniques. The common machining methods include:

- Diamond Cutting: Diamond-coated tools are essential for cutting fully sintered boron carbide, enabling accurate shaping and smooth surface finishes.

- Precision Grinding: Used to achieve fine tolerances and clean finishes. This process is slow and requires careful handling to avoid micro-cracks or structural damage.

- Ultrasonic Machining: Applies high-frequency vibrations with abrasive slurry to remove material gently, suitable for intricate and delicate shapes.

- Laser Cutting: A non-contact technique effective for pre-sintered material or thin sections, offering clean edges with minimal thermal stress.

- Green Machining: Carried out before sintering, allowing easier shaping of complex geometries. However, post-sintering shrinkage (~20%) must be accounted for in final dimensions.

Boron Carbide Ceramic Packaging

Boron Carbide ceramic products are typically packaged in vacuum-sealed bags to prevent moisture or contamination and wrapped with foam to cushion vibrations and impacts during transport, ensuring the quality of products in their original condition.

Download

Get A Quote

We will check and get back to you in 24 hours.