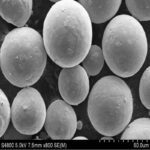

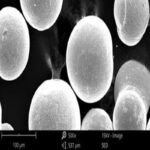

Boron Carbide Spherical Powder

Boron Carbide Spherical Powder

Purity: 99.5% – 99.99%

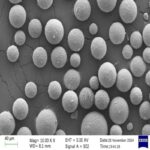

Particle Size: 0-15 μm, 15-53 μm, 45-105 μm, 75-150 μm, or customized

Boron Carbide Spherical Powder is a high-performance material known for its exceptional hardness, low density, and outstanding chemical stability. Recognized as one of the hardest substances on Earth—second only to diamond—Boron Carbide (B₄C) is widely used in industries requiring lightweight yet highly durable materials. What sets the spherical form apart is its superior flowability, packing density, and uniformity compared to irregular-shaped particles, making it especially valuable in applications like additive manufacturing, thermal spray coatings, and powder metallurgy. we can supply high-quality Boron Carbide Spherical Powder with various specifications and competitive prices, offering customized solutions to meet specific requirements.

Or email us at sales@heegermaterials.com.Boron Carbide Spherical Powder Data Sheet

| Reference Code: | SP-2043 |

| Purity: | 99.5% – 99.99% |

| CAS: | 12069-32-8 |

| Color: | Dark grey |

| Chemical Formula: | B₄C |

| Particle Size: | 0-15 μm, 15-53 μm, 45-105 μm, 75-150 μm, or customized |

| Density: | 2.52 g/cm³ |

| Melting Point: | 2,445°C |

| shape: | Spherical |

Boron Carbide Spherical Powder Description

Boron Carbide Spherical Powder combines the extraordinary properties of traditional boron carbide with the enhanced functionality of a spherical morphology. Its ultra-high hardness, excellent thermal stability, and chemical inertness make it a go-to material in demanding environments. The spherical shape significantly improves powder flowability and packing uniformity, which is crucial for precision in additive manufacturing, consistent layering in thermal spraying, and efficient compaction in powder metallurgy. In addition to the spherical form, we also provide irregular boron carbide powder to meet a variety of processing needs and cost-performance considerations. Whether it’s for creating lightweight ballistic armor, producing wear-resistant coatings, or reinforcing high-performance components, this advanced powder delivers both strength and process efficiency.

Boron Carbide Spherical Powder Features

- Ultra-High Hardness: One of the hardest materials known, second only to diamond, ideal for extreme wear resistance.

- Spherical Morphology: Enhances flowability and packing density, making it excellent for additive manufacturing and coating applications.

- Low Density: Offers a high strength-to-weight ratio, suitable for lightweight structural and protective components.

- Excellent Thermal Stability: Maintains integrity under high-temperature conditions, perfect for harsh industrial environments.

- Chemical Inertness: Highly resistant to acids and bases, ensuring long-lasting performance in corrosive settings.

- Uniform Particle Size Distribution: This promotes consistent layer formation and smooth surface finishes during processing.

Boron Carbide Spherical Powder Applications

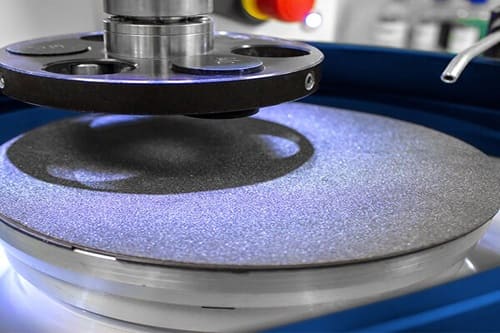

- Additive Manufacturing (3D Printing): Used for producing high-strength, lightweight parts with excellent wear and impact resistance.

- Thermal Spray Coatings: Form durable, protective layers on metal surfaces to improve wear and corrosion resistance.

- Powder Metallurgy: Serves as a hard phase in composite materials for producing cutting tools, dies, and structural parts.

- Armor Materials: Applied in the fabrication of ballistic protection systems, such as body armor and vehicle armor, due to their extreme hardness and low weight.

- Neutron Absorption Components: Utilized in nuclear applications for making control rods and shielding materials because of their high neutron absorption capacity without forming long-lived radioactive isotopes.

Boron Carbide Spherical Powder Packaging

The Boron Carbide Spherical Powder is carefully placed in wooden cases or cartons with additional support from soft materials to prevent any shifting during transportation. This packaging method guarantees the integrity of the products throughout the delivery process.

Download

Get A Quote

We will check and get back to you in 24 hours.