Beryllium Oxide Heat Sinks

Beryllium Oxide Heat Sinks

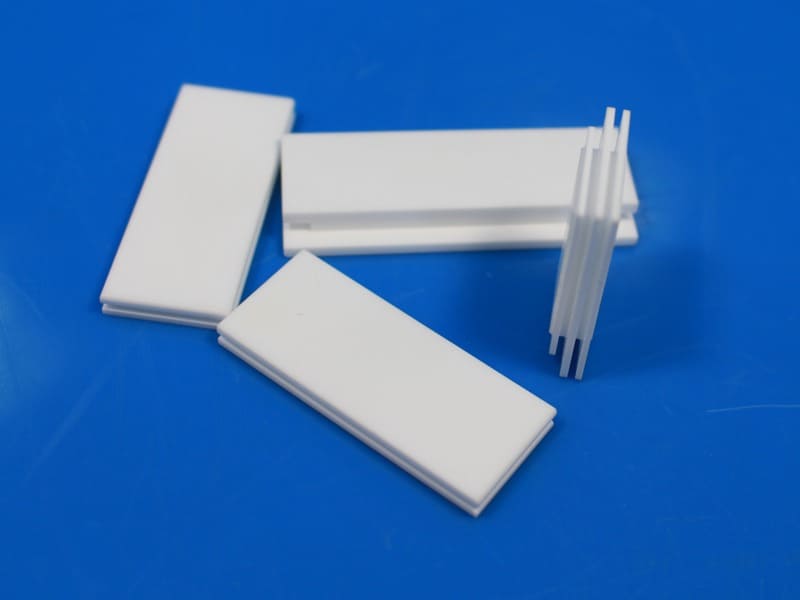

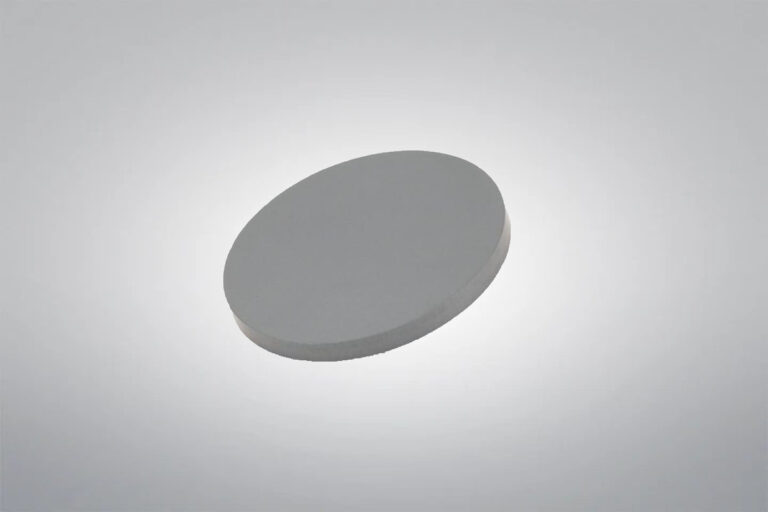

Beryllium Oxide Heat Sinks provide superior thermal conductivity combined with excellent electrical insulation, making them ideal for managing heat in high-power electronic devices such as RF amplifiers, laser diodes, and power transistors. Their strong resistance to thermal shock and chemical corrosion ensures durability and reliable performance in demanding environments like aerospace, telecommunications, and industrial electronics. Precisely machined, these heat sinks help maintain device efficiency and extend operational life. We can supply high-quality Beryllium Oxide Heat Sinks with various specifications and competitive prices, offering customized solutions to meet specific requirements.

Or email us at sales@heegermaterials.com.Beryllium Oxide Heat Sinks Data Sheet

| Color: | White |

| Chemical Formula: | BeO |

| Dimension: | customized |

| Machining Accuracy: | 0.01 mm |

| Surface Roughness: | 0.1 μm |

Beryllium Oxide Heat Sinks Description

Beryllium Oxide Heat Sinks combine outstanding thermal conductivity with electrical insulation, making them an ideal solution for managing heat in compact, high-performance electronic systems. With a thermal conductivity of up to 285 W/m·K, they outperform many traditional ceramics like alumina or aluminum nitride. These heat sinks are widely used in power electronics, RF/microwave devices, and laser systems, where efficient heat dissipation is critical to prevent device failure and ensure long-term stability. Their low dielectric constant and high mechanical strength also support miniaturization and reliability in demanding environments.

Beryllium Oxide Heat Sinks Chemical Compositions

| Element | Content (ppm) |

|---|---|

| Boron (B) | 2 |

| Aluminum (Al) | 46 |

| Chromium (Cr) | 8 |

| Iron (Fe) | 32 |

| Magnesium (Mg) | 1000 |

| Manganese (Mn) | 2 |

| Nickel (Ni) | 9 |

| Titanium (Ti) | 5 |

| Sodium (Na) | 173 |

| Calcium (Ca) | 31 |

| Silicon (Si) | 2100 |

Beryllium Oxide Heat Sinks Features

- Exceptional Thermal Conductivity: Offers up to 285 W/m·K, enabling efficient heat dissipation in compact systems.

- Electrical Insulation: Combines thermal management with dielectric strength, ideal for electronic isolation.

- High Mechanical Strength: Maintains structural integrity under thermal and mechanical stress.

- Low Dielectric Constant: Suitable for high-frequency applications like RF and microwave systems.

- Chemical Stability: Resistant to oxidation and corrosion, ensuring durability in harsh environments.

Beryllium Oxide Heat Sinks Applications

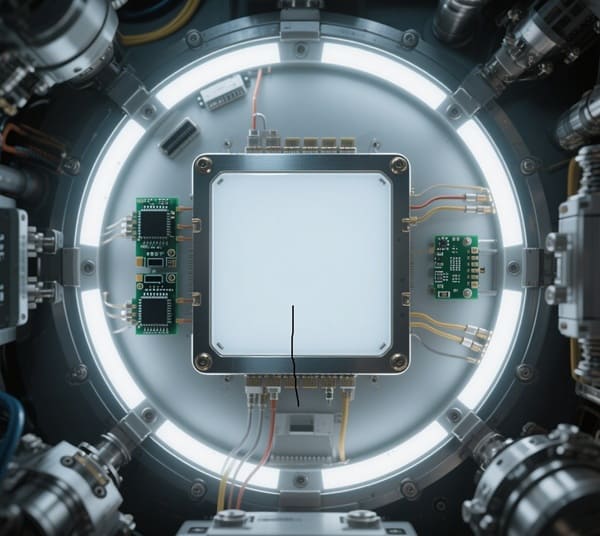

- Power Electronics: Enhances cooling performance in IGBT modules, MOSFETs, and power amplifiers.

- RF and Microwave Devices: Used in TWTs, klystrons, and other vacuum tube devices for stable operation.

- Laser Systems: Maintains optimal temperature for high-power laser diodes and optics.

- Aerospace Electronics: Supports heat control in avionics and satellite communication modules.

- Medical Equipment: Ensures thermal stability in MRI coils, defibrillators, and diagnostic electronics.

Beryllium Oxide Ceramic Properties

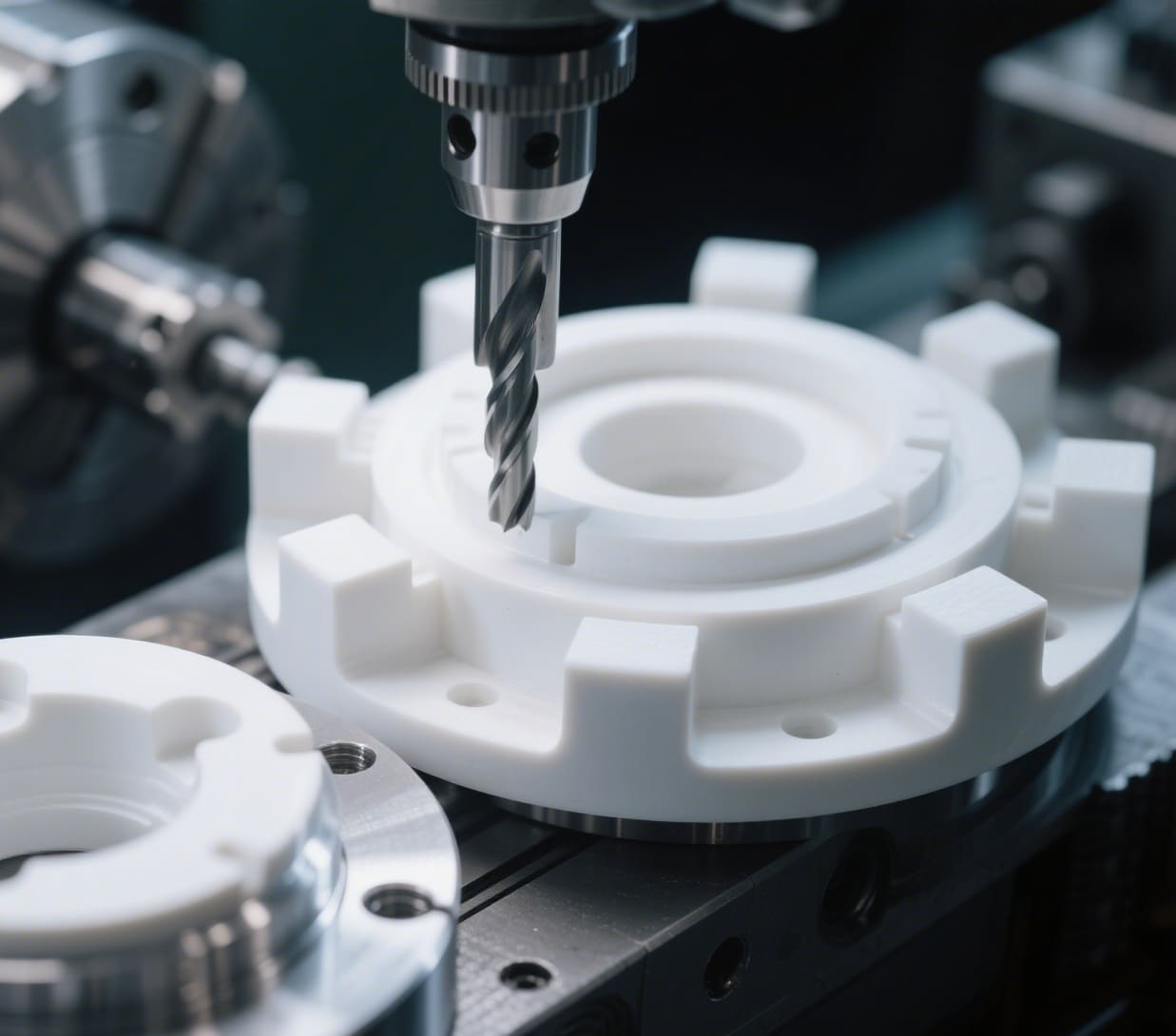

Beryllium Oxide Ceramic Material Machining

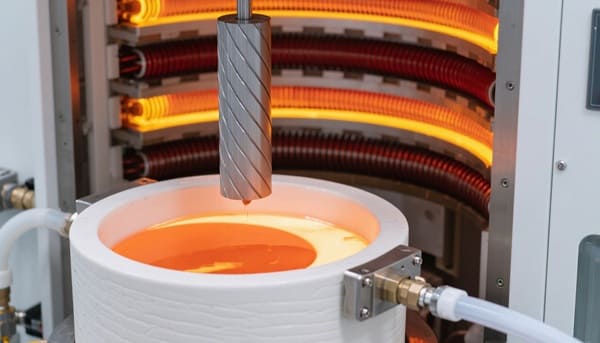

Beryllium Oxide (BeO) Ceramic is valued for its exceptional thermal conductivity, electrical insulation, and high melting point. These qualities make it widely used in electronics and high-temperature applications, but its hardness and brittleness require special machining approaches. Key machining considerations include:

- Cutting: Precision diamond-coated tools or laser cutting are essential to avoid microcracks and maintain clean edges, as BeO’s brittleness can lead to chipping during conventional cutting.

- Grinding: Fine diamond grinding wheels enable accurate shaping and surface finishing while minimizing the risk of fractures, especially important for small or complex parts.

- Drilling: Ultrasonic machining or abrasive waterjet methods are preferred to produce precise holes without causing thermal damage or cracks.

- Surface Finishing: Polishing techniques enhance surface smoothness and electrical insulation properties, crucial for applications demanding high dielectric performance and reliability.

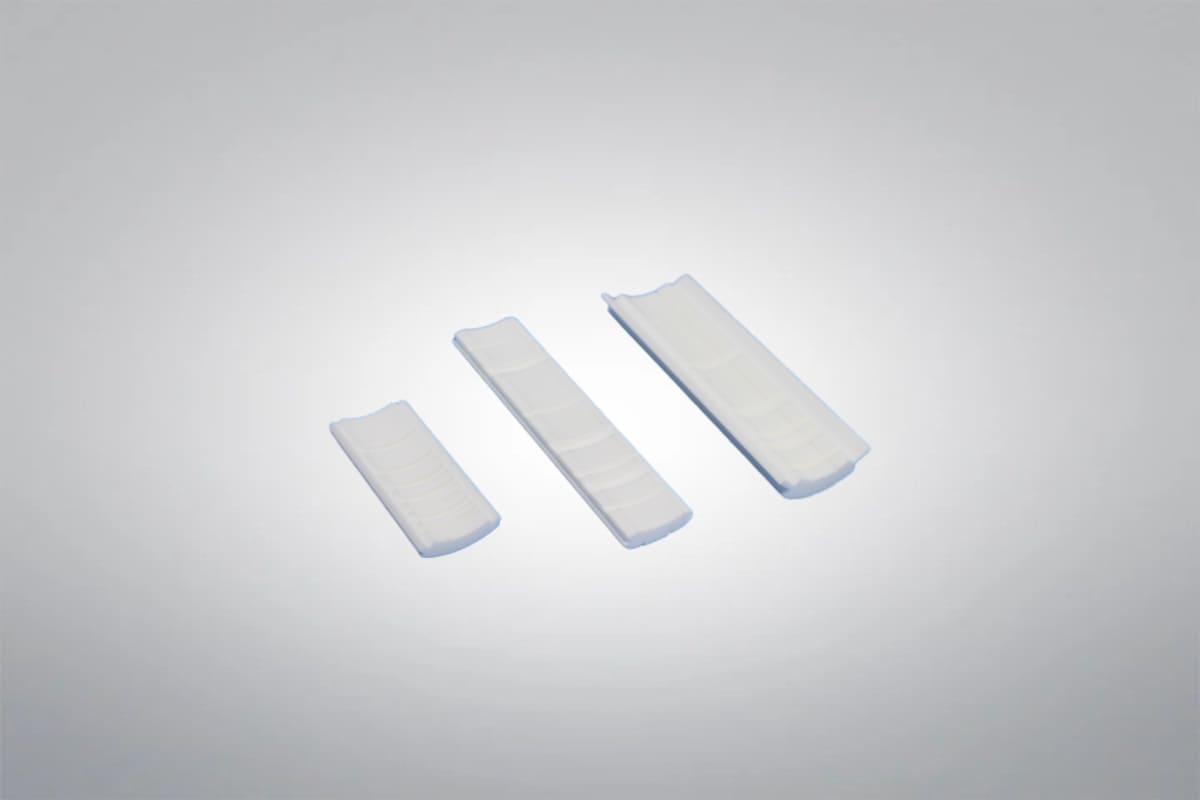

Beryllium Oxide Ceramic Packaging

Beryllium oxide ceramic products are typically packaged in vacuum-sealed bags to prevent moisture or contamination and wrapped with foam to cushion vibrations and impacts during transport, ensuring the quality of products in their original condition.

Download

Get A Quote

We will check and get back to you in 24 hours.