Aluminum Silicon Carbide Heat Sink

Aluminum Silicon Carbide Heat Sink

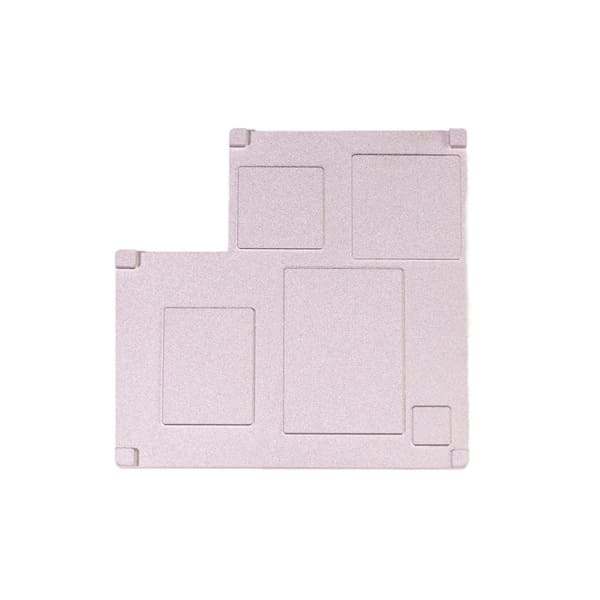

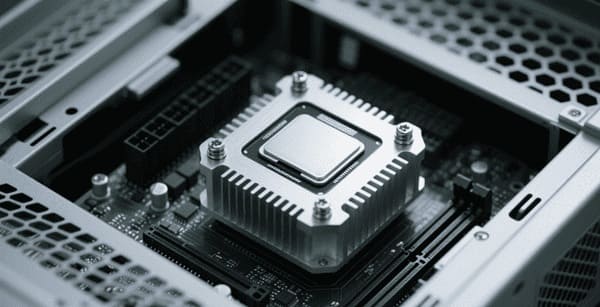

Aluminum Silicon Carbide Heat Sink is a lightweight metal-ceramic composite made by uniformly dispersing silicon carbide particles in an aluminum alloy matrix, with SiC content adjustable from 15% to 70% to meet specific thermal and mechanical needs. Combining high thermal conductivity, low thermal expansion, and excellent rigidity, Al-SiC is widely used for electronic chip and power module heat sinks, microprocessor lids, and CPU or server chip thermal spreaders. We can supply high-quality Aluminum Silicon Carbide Heat Sink with various specifications and competitive prices, offering customized solutions to meet specific requirements.

Or email us at sales@heegermaterials.com.Aluminum Silicon Carbide Heat Sink Data Sheet

| Chemical Formula: | Al-SiC |

| Shape: | Substrate |

| Dimension: | Standard or customized |

Aluminum Silicon Carbide Heat Sink Description

Aluminum Silicon Carbide Heat Sink is a high-performance thermal management material with low thermal expansion, high thermal conductivity, lightweight, and high stiffness, ideal for both military and civilian microelectronics. Its coefficient of thermal expansion matches dielectric substrates, ceramic BGAs, LTCC, and PCBs, ensuring excellent thermal and mechanical reliability, while high thermal conductivity enables efficient heat dissipation and high strength protects integrated circuits during assembly. Typical uses include flip-chip lids, heat sinks for ASICs and power modules, and CPU or server processor heat spreaders, making Al-SiC a preferred choice for demanding electronics.

Aluminum Silicon Carbide Material Chemical Composition

| Technology | Material Reference Code | Volume Fraction | Performance Advantages | Application Directions | |

| SiC (%) | Al (%) | ||||

| RSPM + HIP (Rapid Solidification + HIP) | HMA15 | 15 | 85 | ✔High specific strength & stiffness ✔Low density ✔Excellent wear resistance ✔Good heat resistance | ✔Lightweight and wear-resistant components ✔Alternative to aluminum alloys, cast steel, cast iron, and titanium alloys ✔Brake components, pistons, connecting rods, fighter belly fins, helicopter rotor forgings |

| HMA30 | 30 | 70 | |||

| HMA40 | 40 | 60 | ✔High specific strength & stiffness ✔High micro-yield strength ✔Low thermal expansion ✔High thermal conductivity | ✔Aerospace and defense applications ✔Optical mirrors, inertial navigation system components ✔Alternative to beryllium, glass-ceramics, quartz glass | |

| HMA50 | 50 | 50 | |||

| Pressure Infiltration (PI) | HMA55 | 55 | 45 | ✔High specific modulus ✔Low density ✔Low thermal expansion ✔High thermal conductivity | ✔Thermal management materials for military and civilian use ✔Military IGBT substrates, PCB substrates, heat dissipation baseplates ✔Electronic component bases and housings, power amplifier module housings and bases ✔Alternative to W/Cu, Mo/Cu, Kovar alloys |

| HMA65 | 65 | 35 | |||

| HMA70 | 70 | 30 | |||

Aluminum Silicon Carbide Heat Sink Features

- Advanced Composite Composition: Made of silicon carbide particles reinforced within an aluminum matrix, combining the high hardness of ceramics with the toughness of metal.

- Dual-Network Structure: Produced by infiltrating molten aluminum into a 3D foam SiC framework, resulting in a strong interpenetrating network of SiC and Al.

- High Thermal Conductivity: Offers excellent heat transfer performance in the range of 180–220 W/m·K, ensuring rapid heat dissipation.

- Low Thermal Expansion: CTE closely matches semiconductor materials like Si and GaAs, minimizing thermal stress and preventing fatigue damage.

- Lightweight & Durable: Features low density, high hardness, strong flexural strength, and exceptional corrosion resistance for stable performance in demanding environments.

Aluminum Silicon Carbide Heat Sink Applications

- Electronic Chip Cooling: Used as heat sinks for specialized integrated circuits (ICs) to efficiently dissipate heat and maintain performance.

- Power Supply Modules: Provides effective thermal management for power electronics, ensuring reliability under high loads.

- Microprocessor Covers and Heat Spreaders: Act as a protective cover with excellent heat conduction for CPUs and MPUs in computers and servers.

- LED Lighting Systems: Helps manage thermal output in high-power LED arrays, extending lifespan and efficiency.

- Aerospace Electronics: Utilized in military and aerospace microelectronics where lightweight, high thermal conductivity, and low thermal expansion are critical.

Aluminum Silicon Carbide Material Properties

Aluminum Silicon Carbide Packaging

Aluminum silicon carbide ceramic products are typically packaged in vacuum-sealed bags to prevent moisture or contamination and wrapped with foam to cushion vibrations and impacts during transport, ensuring the quality of products in their original condition.

Download

Get A Quote

We will check and get back to you in 24 hours.