Aluminum Nitride Spherical Powder

Aluminum Nitride Spherical Powder

Purity: 99%-99.9%

Particle Size: 30-120 μm, or customized

Aluminum Nitride Spherical Powder is a high-performance ceramic material, widely used as a filler powder for high thermal conductivity theraml grease, gels, pads, adhesives, and high thermal conductivity plastics. As a leading supplier and manufacturer of premium aluminum nitride products, we can supply high-quality aluminum nitride spherical powders with various specifications and competitive prices, offering customized solutions to meet specific requirements.

Or email us at sales@heegermaterials.com.Aluminum Nitride Spherical Powder Data Sheet

| Reference Code: | HM1974 |

| Purity: | 99%-99.9% |

| Particle Size: | 30-120 μm or customized |

| CAS: | 24304-00-5 |

| Melting Point: | 2200℃ |

| Boiling Point: | 2249℃ |

Aluminum Nitride Spherical Powder

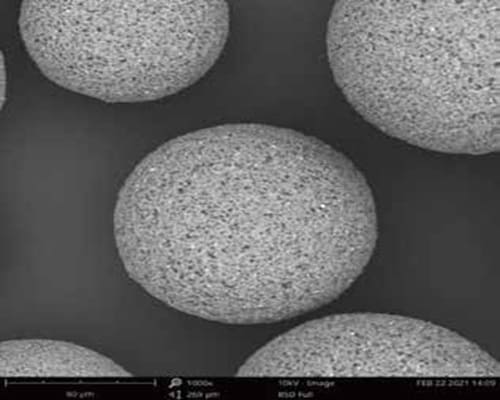

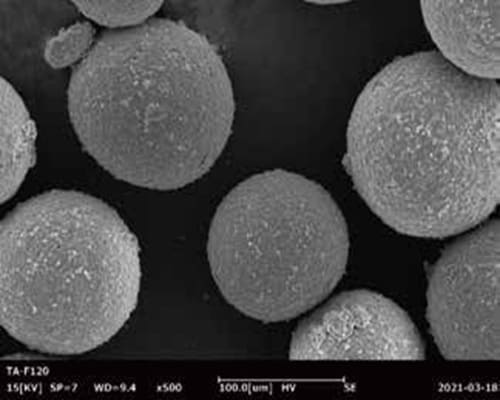

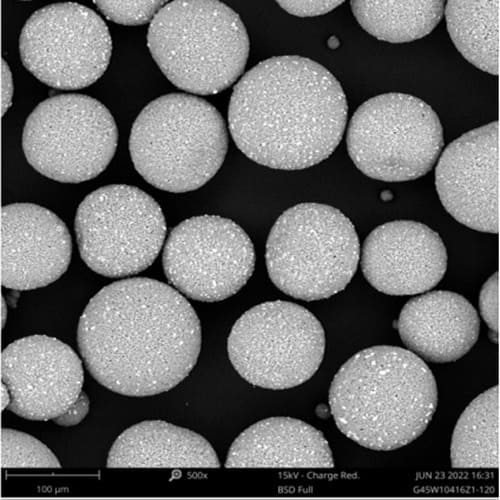

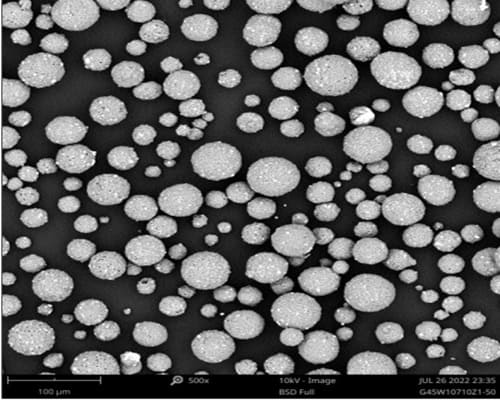

Aluminum Nitride Spherical Powder is manufactured using a spray granulation method, followed by processes such as sintering and classification. It is characterized by high thermal conductivity, excellent sphericity, high purity, low specific area, narrow particle size distribution, and good flowability. It is widely used as a thermal interface material. Advanced Ceramics Hub can provide customized solutions in purity and particle size to meet various industrial and research applications.

Aluminum Nitride Spherical Powder Specifications

| Properties | Unit | Product | |||||

| TA-S30 | TA-S50 | TA-S80 | TA-S120 | ||||

| Particle Size | D10 | μm | 24.1 | 31.75 | 49.6 | 71.0 | |

| D50 | μm | 38.3 | 50.75 | 74.7 | 107.5 | ||

| D90 | μm | 61.5 | 80.11 | 111.5 | 134.0 | ||

| Specific Surface Area | m2/g | 0.05 | 0.05 | 0.03 | 0.03 | ||

| Moisture | % | 0.08 | 0.07 | 0.06 | 0.02 | ||

| True Density | g/cm3 | 3.29 | 3.30 | 3.30 | 3.32 | ||

| Tap Density | g/cm3 | 2.00 | 2.02 | 2.10 | 2.21 | ||

| Chemical Composition | O | % | 1.20 | 1.20 | 1.32 | 1.24 | |

| C | ppm | 126 | 120 | 119 | 119 | ||

| Si | ppm | 40 | 40 | 40 | 40 | ||

| Fe | ppm | 20 | 20 | 20 | 20 | ||

| Na | ppm | 15 | 15 | 15 | 15 | ||

Aluminum Nitride Spherical Powder Morphology

Aluminum Nitride Spherical Powder Features

- High sphericity

- High thermal conductivity

- High packing density

- Good flowability

- Small specific surface area

- Narrow particle size distribution

Aluminum Nitride Powder Solutions

Spherical Powder

Aluminum Nitride (AlN) Spherical Powder, made by spray granulation, sintering, and classification, offers high thermal conductivity, purity, sphericity, and good flowability. It’s widely used as a thermal interface material.

Aluminum Nitride Spherical Powder Applications

- Thermal management materials (e.g., heat sinks, substrates)

- 3D printing and additive manufacturing

- High-performance ceramics

- Filler in thermal interface materials (TIMs) for electronics (e.g., LEDs, power modules, electric vehicle components)

Aluminum Nitride Spherical Powder Packaging

The Aluminum Nitride Spherical Powder is carefully placed in wooden cases or cartons with additional support from soft materials to prevent any shifting during transportation. This packaging method guarantees the integrity of the products throughout the delivery process.

Download

Get A Quote

We will check and get back to you in 24 hours.