TiTaAlC MAX Phase Powder

TiTaAlC MAX Phase Powder

TiTaAlC MAX Phase Powder is a titanium-tantalum layered carbide with excellent thermal stability, oxidation resistance, and mechanical strength. It is suitable for high-temperature components, protective coatings, and MXene-related applications. We can supply high-quality VCrAlC MAX Phase Powder with various specifications and competitive prices, offering customized solutions to meet specific requirements.

Or email us at sales@heegermaterials.com.TiTaAlC MAX Phase Powder Data Sheet

| Purity: | ≥98% |

| Size : | 200~500 mesh or customized |

TiTaAlC MAX Phase Powder Description

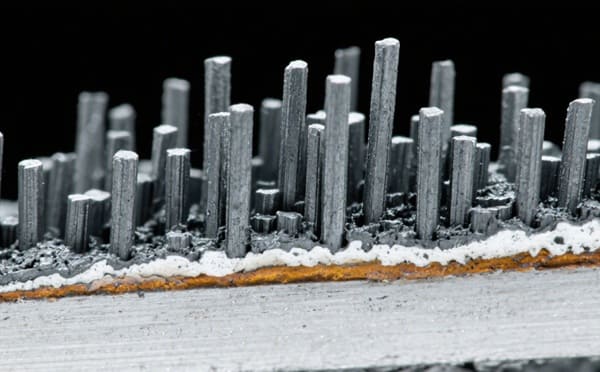

TiTaAlC MAX Phase Powder is a layered ternary carbide combining titanium, tantalum, aluminum, and carbon into a stable hexagonal structure. This unique MAX phase material exhibits an exceptional balance of metallic conductivity and ceramic-like properties, including high mechanical strength, thermal stability, and oxidation resistance. The incorporation of tantalum enhances chemical stability and toughness, making TiTaAlC suitable for high-temperature structural applications, protective coatings, and as a precursor for MXene synthesis. Its layered structure also offers potential in advanced energy storage, catalysis, and electronic devices, providing versatility for both research and industrial use.

TiTaAlC MAX Phase Powder Features

- Layered Hexagonal Structure: Exhibits a stable hexagonal layered crystal structure typical of MAX phases, combining metallic and ceramic properties.

- High Thermal and Oxidation Resistance: Maintains structural integrity under high-temperature and oxidative conditions.

- Mechanical Strength and Toughness: Offers excellent fracture toughness and damage tolerance compared to conventional ceramics.

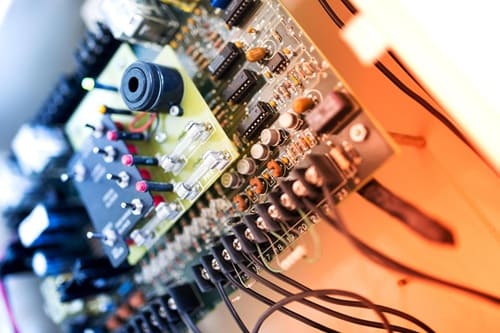

- Electrical and Thermal Conductivity: Provides reliable conductivity, suitable for functional applications.

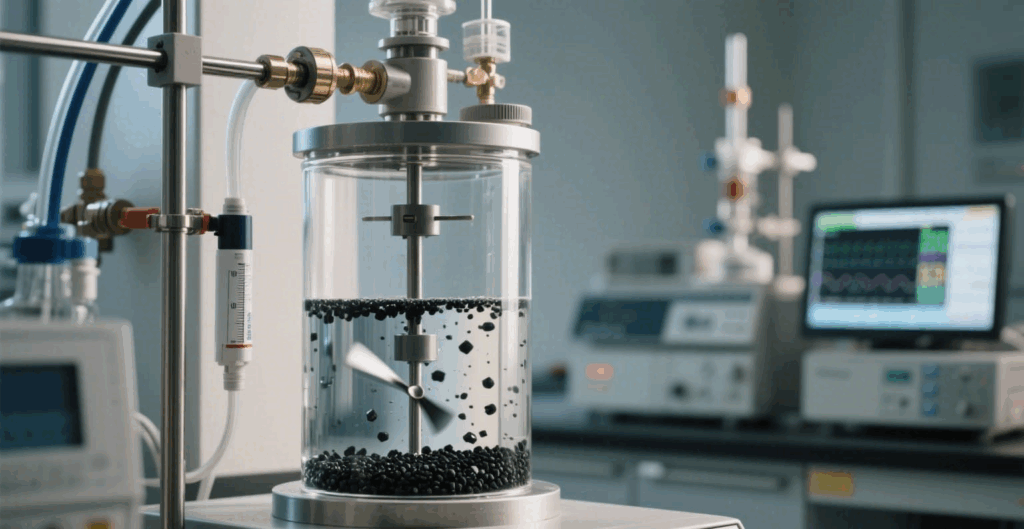

- MXene Precursor Potential: Can be used to produce TiTaC-based MXenes for energy storage, catalysis, and electronic devices.

TiTaAlC MAX Phase Powder Applications

- High-Temperature Coatings: Applied in protective coatings for aerospace and industrial components exposed to heat and oxidation.

- Structural Materials: Suitable for high-temperature mechanical parts requiring strength, toughness, and thermal stability.

- Energy Storage Devices: Serves as a precursor for MXenes used in batteries, supercapacitors, and electrochemical systems.

- Catalysis: Utilized in catalytic processes due to its layered structure and transition metal composition.

- Electronic Components: Supports conductive and stable layers in advanced electronic and functional devices.

TiTaAlC MAX Phase Powder Packaging

TiTaAlC MAX Phase Powder is typically packaged in sealed, moisture-proof plastic bags, then placed in sturdy drum containers or fiber cartons to prevent contamination and ensure safe transport. Standard packaging sizes include 1 kg, 5 kg, and 10 kg options, with custom packaging available upon request to meet specific usage or storage needs.

Download

Get A Quote

We will check and get back to you in 24 hours.