Ti2AlC MAX Phase Powder

Ti2AlC MAX Phase Powder

Ti2AlC MAX Phase Powder is a layered carbide material that bridges the gap between metals and ceramics. It offers high conductivity, oxidation resistance, and excellent thermal shock stability, making it ideal for advanced applications such as coatings, structural parts, and electronic components. We can supply high-quality Ti2AlC MAX Phase Powder with various specifications and competitive prices, offering customized solutions to meet specific requirements.

Or email us at sales@heegermaterials.com.Ti2AlC MAX Phase Powder Data Sheet

| Purity: | ≥98% |

| Size : | 200~500 mesh or customized |

Ti2AlC MAX Phase Powder Description

Ti2AlC MAX Phase Powder is a ternary carbide with a layered structure that combines metallic conductivity and machinability with ceramic traits such as oxidation resistance and high-temperature stability. It shows excellent thermal shock resistance, low thermal expansion, and reliable mechanical strength, making it suitable for demanding applications in aerospace, energy, and protective coatings. In powder form, Ti2AlC can be processed through sintering or additive manufacturing to produce advanced components.

Ti2AlC MAX Phase Powder Features

- Layered Nanolaminated Structure: Provides a unique balance of metallic conductivity and ceramic-like stability.

- Excellent Thermal Shock Resistance: Maintains integrity under rapid temperature changes.

- Oxidation Resistance: Ensures durability in high-temperature and oxidative environments.

- Good Machinability: Easier to process compared to traditional ceramics, suitable for shaping and sintering.

- Low Thermal Expansion: Enhances dimensional stability for precision components.

Ti2AlC MAX Phase Powder Applications

- Aerospace Components: Used in high-temperature turbine parts and heat shields for improved thermal stability.

- Electronics: Serves as conductive and thermally stable layers in electronic devices.

- Energy Systems: Applied in heat exchangers and nuclear components due to its oxidation resistance.

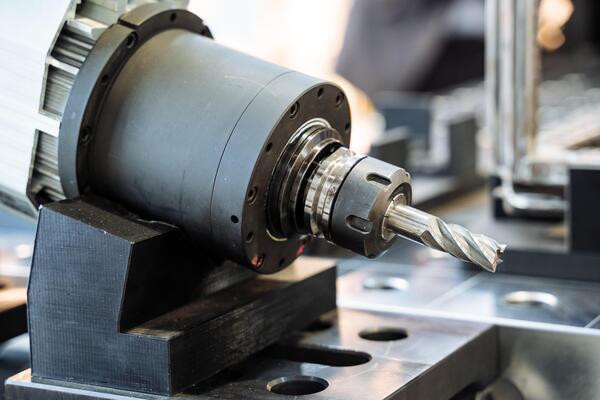

- Cutting Tools and Coatings: Enhances wear resistance and extends tool life under extreme conditions.

- Additive Manufacturing: Enables fabrication of complex, high-performance ceramic-metal hybrid structures.

Ti2AlC MAX Phase Powder Packaging

Ti2AlC MAX Phase Powder is typically packaged in sealed, moisture-proof plastic bags, then placed in sturdy drum containers or fiber cartons to prevent contamination and ensure safe transport. Standard packaging sizes include 1 kg, 5 kg, and 10 kg options, with custom packaging available upon request to meet specific usage or storage needs.

Download

Get A Quote

We will check and get back to you in 24 hours.