PZT Ring

PZT Ring

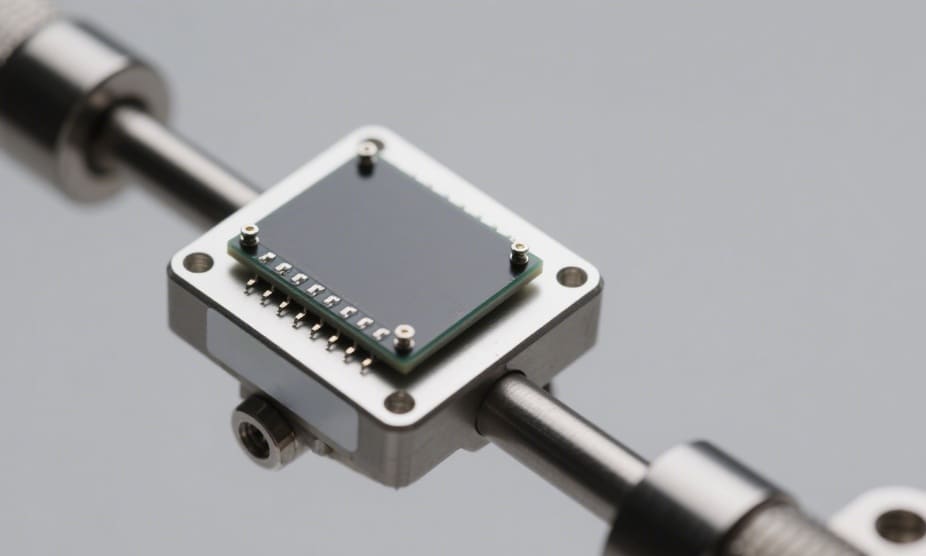

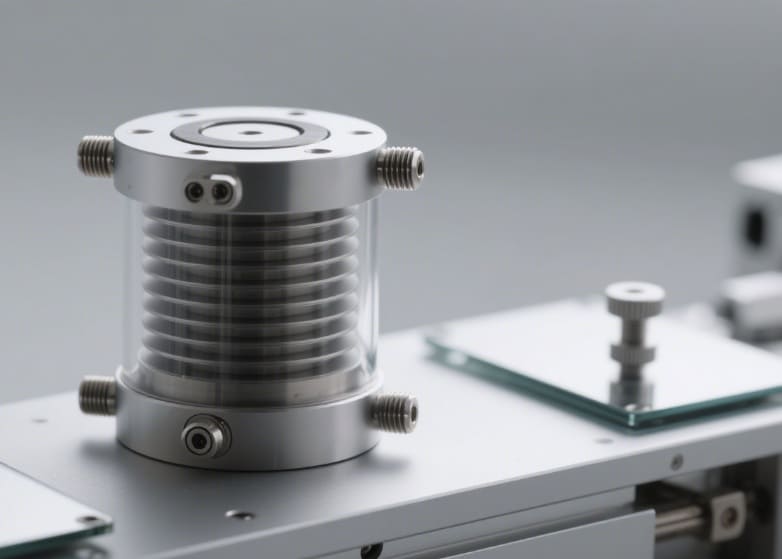

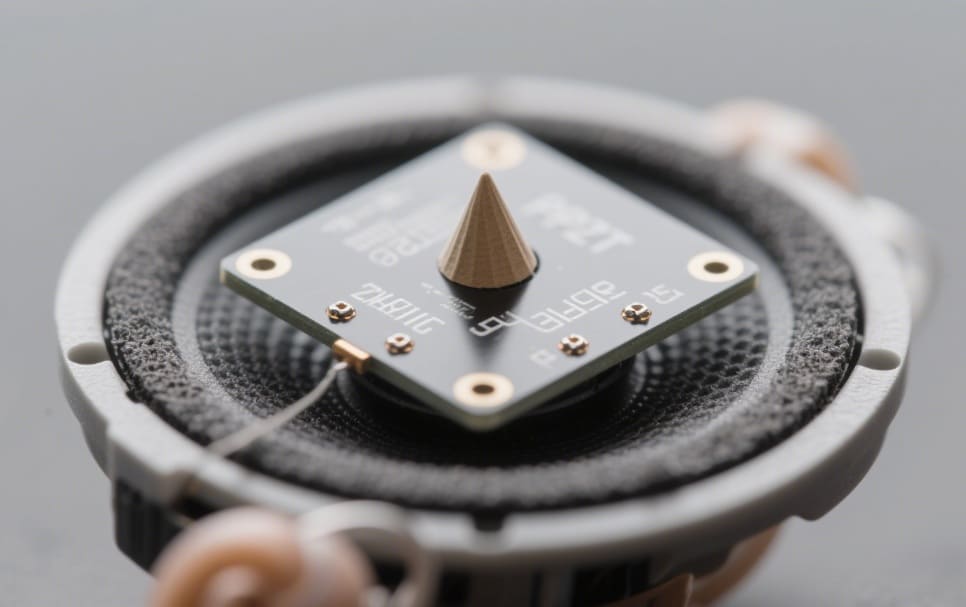

PZT ring is a high-performance piezoelectric ceramic part known for its stable vibration response and efficient energy conversion. It is widely used in ultrasonic cleaning, medical imaging, and sensing devices, with customizable sizes to meet diverse application needs. We can supply high-quality PZT Ring with various specifications and competitive prices, offering customized solutions to meet specific requirements.

Or email us at sales@heegermaterials.com.PZT Ring Data Sheet

| Color: | White |

| Material: | Lead Zirconate Titanate (PZT) |

| Shape: | Ring |

| Dimension: | Standard or customized |

| Outer Diameter: | 5 mm ~ 140 mm |

| Height: | 1 mm ~ 60 mm |

| Inner Diameter: | 1 mm |

| Wall Thickness: | 1 mm |

| Customization: | Available |

PZT Ring Description

PZT ring is a circular piezoelectric ceramic component designed to convert electrical energy into mechanical vibrations and vice versa efficiently. With its annular shape, it offers excellent resonance characteristics and uniform vibration distribution, making it ideal for ultrasonic transducers, underwater sonar devices, and precision sensing equipment. Its dimensions, inner and outer diameters, and thickness can be customized to match specific frequency and performance requirements, ensuring optimal results for industrial, medical, and scientific applications.

PZT Ring Specifications

| Model | Outer Diameter OD [mm] (± tolerance) | Inner Diameter ID [mm] (± tolerance) | Height H [mm] | Driving Voltage [V] | Displacement [μm] ±15% | Capacitance [nF] ±15% | Resonant Frequency [kHz] ±20% | Stiffness [N/μm] ±20% | Thrust [N] ±20% | Weight [g] ±5% |

|---|---|---|---|---|---|---|---|---|---|---|

| NAC2121 | 6 (±0.2) | 2 (±0.1) | 2 | 200 | 3.3 | 105 | 486 | 321 | 1060 | 0.38 |

| NAC2122 | 8 (±0.25) | 3 (±0.1) | 2 | 200 | 3.3 | 200 | 486 | 548 | 1810 | 0.67 |

| NAC2123 | 12 (±0.4) | 6 (±0.2) | 2 | 200 | 3.3 | 380 | 486 | 1079 | 3560 | 1.36 |

| NAC2124 | 15 (±0.45) | 9 (±0.3) | 2 | 200 | 3.3 | 510 | 486 | 1439 | 4750 | 1.75 |

| NAC2125 | 20 (±0.6) | 12 (±0.4) | 2 | 200 | 3.3 | 890 | 486 | 2561 | 8450 | 3.13 |

PZT Ring Features

- High Piezoelectric Sensitivity: Converts mechanical energy to electrical signals efficiently for precise sensing and actuation.

- Excellent Dimensional Stability: Maintains shape and performance under varying temperatures and mechanical stress.

- Wide Frequency Response: Supports applications from low-frequency vibration detection to high-frequency ultrasonic transmission.

- Customizable Dimensions: Outer diameter, inner diameter, and thickness can be adapted to specific design requirements.

- Durable Ceramic Composition: Resistant to wear, corrosion, and environmental degradation for long service life.

PZT Ring Applications

- Ultrasonic Transducers: Used in ultrasonic cleaning, welding, and flaw detection equipment.

- Medical Imaging Devices: Functions as a key element in ultrasound probes for diagnostic imaging.

- Vibration Sensors: Detect structural vibrations in machinery, vehicles, and industrial equipment.

- Underwater Sonar Systems: Provide efficient acoustic wave transmission for marine navigation and communication.

- Actuators in Precision Equipment: Enable micro-positioning and motion control in robotics and automation systems.

PZT Ceramic Material Properties

| Properties | Materials | |||||||||||

| PZT4 | PZT5 | PZT8 | ||||||||||

| 840 | 841 | 842** | 844** | 850 | 851** | 854 | 855 | 860 | 880 | 881** | ||

| Relative Permittivity | KT | 1275 | 1375 | 1375 | 1500 | 1900 | 1950 | 2750 | 3300 | 1200 | 1050 | 1030 |

| Dielectric Loss Factor (%) | tan δ | 0.60 | 0.40 | 0.45 | 0.40 | ≤ 2.00 | 1.50 | ≤ 2.00 | ≤ 2.50 | ≤2.00 | 0.40 | 0.40 |

| Curie Temperature (°C) | Tc | 325 | 320 | 325 | 320 | 360 | 360 | 250 | 200 | 360 | 310 | 310 |

| Electromechanical Coupling Coefficient | kp | 0.59 | 0.60 | 0.65 | 0.68 | 0.63 | 0.71 | 0.66 | 0.68 | 0.50 | 0.50 | 0.58 |

| k33 | 0.72 | 0.68 | – | – | 0.72 | – | 0.68 | 0.76 | 0.45 | 0.62 | – | |

| k31 | 0.35 | 0.33 | – | – | 0.36 | – | – | 0.40 | – | 0.30 | – | |

| k15 | 0.70 | 0.67 | – | – | 0.68 | – | – | 0.66 | – | 0.55 | – | |

| kt | – | – | 0.48 | 0.48 | – | 0.51 | – | – | – | – | 0.46 | |

| Piezoelectric Charge Constant (10⁻¹² C/N or 10⁻¹² m/V) | d33 | 290 | 300 | 300 | 300 | 400 | 400 | 600 | 630 | 380 | 215 | 220 |

| -d31 | 125 | 109 | – | – | 175 | – | 260 | 276 | – | 95 | – | |

| d15 | 480 | 450 | – | – | 590 | – | 625 | 720 | – | 330 | – | |

| Piezoelectric Voltage Constant (10⁻³ Vm/N or 10⁻³ m²/C) | g33 | 26.5 | 25.5 | 26.3 | 24.5 | 24.8 | 24.8 | 25.5 | 21.0 | 38.0 | 25.0 | 26.7 |

| -g31 | 11.0 | 10.5 | – | – | 12.4 | – | – | 9.0 | – | 10.0 | – | |

| g15 | 38.0 | 35.0 | – | – | 36.0 | – | – | 27.0 | – | 28.0 | – | |

| Young’s Modulus (10¹⁰ N/m²) | YE11 | 8.0 | 7.6 | 8.0 | 7.6 | 6.3 | 6.3 | 6.0 | 5.9 | – | 9.0 | 9.0 |

| YE33 | 6.8 | 6.3 | 6.8 | 6.3 | 5.4 | 5.4 | 5.2 | 5.1 | – | 7.2 | 7.2 | |

| Frequency Constant (Hz·m or m/s) | NL (Length Direction) | 1524 | 1700 | – | – | 1500 | – | – | 1390 | – | 1725 | – |

| NT (Thickness Direction) | 2005 | 2005 | 2050 | 2050 | 2040 | 2040 | 2000 | 2079 | 1390 | 2110 | 2050 | |

| NP (Planar Direction) | 2130 | 2055 | 2230 | 2250 | 1980 | 2080 | 1972 | 1920 | 1900 | 2120 | 2300 | |

| Density (g/cm³) | ρ | 7.6 | 7.6 | 7.6 | 7.7 | 7.6 | 7.6 | 7.6 | 7.6 | 6.6 | 7.6 | 7.6 |

| Mechanical Quality Factor | Qm | 500 | 1400 | 600 | 1500 | 80 | 80 | 70 | 65 | 50 | 1000 | 1000 |

| Acoustic Impedance (Mrayl) | – | – | – | – | 31.5 | – | – | – | 16.5 | – | – | |

Notes:

- @ 1 kHz, low electric field

- Materials 842, 844, 851, and 881 are stock products provided for reference only and are not available for customization.

PZT Ceramic Tolerances

PZT Material Property Parameter Tolerances:

| Parameter | Standard Tolerance | Optional Stricter Tolerance Available |

|---|---|---|

| Capacitance | ±20% | Yes |

| d33 (Piezo Coefficient) | ±20% | Yes |

| Frequency | ±5% | ±0.5% |

Dimension Tolerances:

| Shape & Dimension | Standard Value Range | Tolerance (±) |

| Disc / Ring / Tube | ||

| Outer Diameter | < 25 mm | 0.25 mm |

| ≥ 25 mm to < 38 mm | 0.38 mm | |

| ≥ 38 mm to < 50 mm | 0.60 mm | |

| ≥ 50 mm | 1.00 mm | |

| Ring / Tube | ||

| Inner Diameter | < 6 mm | 0.25 mm |

| ≥ 6 mm to < 13 mm | 0.38 mm | |

| ≥ 13 mm to < 25 mm | 0.50 mm | |

| ≥ 25 mm | 0.60 mm | |

| Square Plate | ||

| Length or Width | < 13 mm | 0.13 mm |

| ≥ 13 mm to < 25 mm | 0.25 mm | |

| ≥ 25 mm to 38 mm | 0.38 mm | |

| ≥ 38 mm to < 50 mm | 0.60 mm | |

| ≥ 50 mm | 1.00 mm | |

| Thickness | 0.20 mm to < 5.00 mm | 0.025 mm |

| ≥ 5.00 mm | 0.05 mm | |

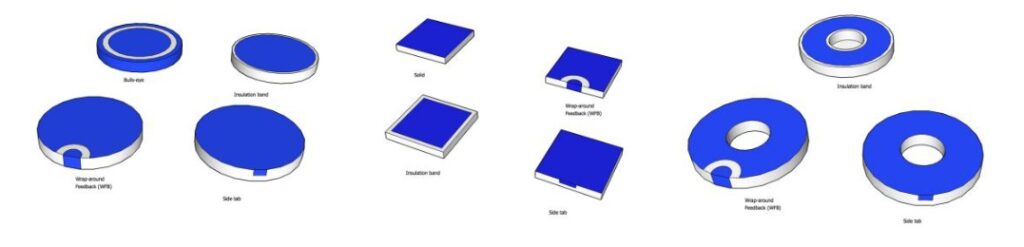

PZT Electrode Specifications

- Standard electrode material: Silver

- Optional electrode materials: Gold, Nickel

- Standard electrode configuration: Solid electrodes covering entire top and bottom surfaces

- Tubular electrode configuration: Electrodes on inner and outer walls (Inner wall: Positive electrode; Outer wall: Negative electrode)

- Custom electrode designs available upon request

| Material | AC Driving Voltage (V/mm) | DC Driving Voltage (V/mm) | Customizable Maximum Voltage (V/mm) |

| PZT4 | 360 ~ 440 | 720 ~ 880 | Up to 1000 |

| PZT5 | 200 ~ 280 | 400 ~ 560 | |

| PZT8 | 360 ~ 440 | 720 ~ 880 |

PZT Ceramic Packaging

PZT ceramic products are typically packaged in vacuum-sealed bags to prevent moisture or contamination and wrapped with foam to cushion vibrations and impacts during transport, ensuring the quality of products in their original condition.

Download

Get A Quote

We will check and get back to you in 24 hours.