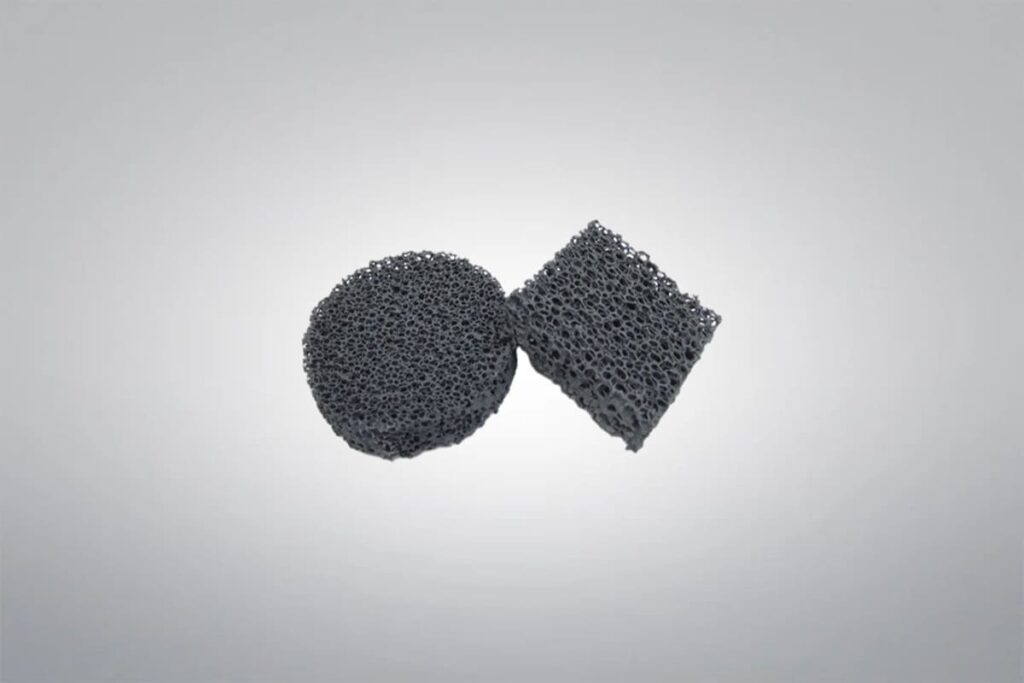

Silicon Carbide Foam

Silicon Carbide Foam

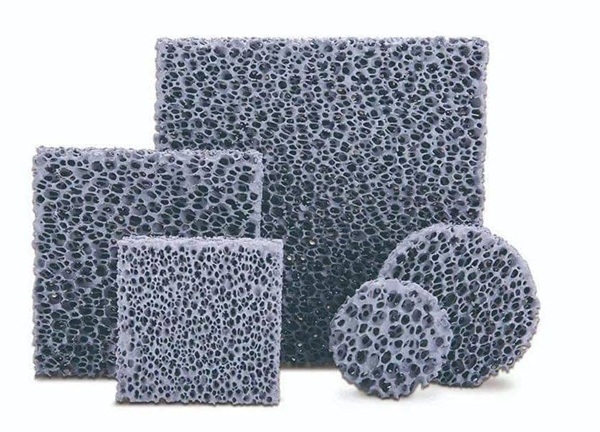

Silicon Carbide Foam offers excellent filtration performance for molten metals, especially ductile and gray iron. Its high strength, thermal shock resistance, and open-cell structure allow efficient impurity removal and reduced turbulence, improving casting quality and mechanical properties. We can supply high-quality silicon carbide foam with various specifications and competitive prices, offering customized solutions to meet specific requirements.

Or email us at sales@heegermaterials.com.Silicon Carbide Foam Data Sheet

| Shape: | Round, Square |

| Chemical Composition | SiC, Al2O3, SiO2 |

| Porosity (%) | 80–90% |

| Pore Density (PPI) | 7PPI–45PPI |

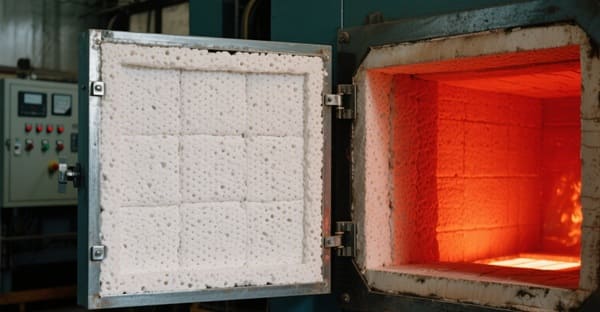

| Operating Temperature (°C) | ≤1500°C |

| Room Temperature Bending Strength (MPa) | 0.8 MPa |

| Room Temperature Compression Strength (MPa) | 1.0 MPa |

| Thermal Shock Resistance | 1100°C to room temperature, 6 times |

| Bulk Density (g/cm³) | 0.4–0.5 g/cm³ |

Silicon Carbide Foam Description

Silicon Carbide Foam is an advanced ceramic material ideal for high-temperature filtration applications, particularly in the casting of ductile iron, gray iron, and copper-based alloys. It offers outstanding thermal shock resistance, mechanical strength, and chemical stability, allowing it to perform reliably in extreme molten metal environments. The open-cell structure enables effective removal of inclusions and impurities, while also reducing turbulence and gas content during pouring. This contributes to improved surface finish, structural integrity, and overall quality of cast components.

Silicon Carbide Foam Stock Specifications

| Shape And Size (mm) | Circular | Φ40×15, Φ50×22, Φ60×22, Φ70×22, Φ80×22, Φ90×22, Φ100×22, Φ125×25, Φ150×30, Φ200×40 |

| Square | 30×50×22, 40×40×22, 50×50×22, 75×50×22, 100×50×22, 75×75×22, 100×75×22, 100×100×22, 150×100×22, 150×150×40, 300×150×40, 125×125×30, 120×120×25 | |

| Custom Dimensions | Sizes can be customized to specific requirements. | |

Silicon Carbide Foam Filtration Capacity

| Dimensions (mm) | Filter Capacity(kg) (10ppi) | Flow Rate (kg/s) (10ppi) | Filter Capacity(kg) (20ppi) | Flow Rate (kg/s) (20ppi) | Filter Capacity(kg) (30ppi) | Flow Rate (kg/s) (30ppi) |

|---|---|---|---|---|---|---|

| 40×40×15 | 64 | 4 | 50 | 3 | 42 | 2 |

| 50×30×22 | 60 | 4 | 47 | 3 | 40 | 2 |

| 50×50×15 | 100 | 6 | 78 | 3.5 | 66 | 3 |

| 50×50×22 | 144 | 9 | 112 | 6 | 95 | 5 |

| 75×50×22 | 220 | 14 | 175 | 10 | 149 | 8 |

| 100×50×22 | 200 | 12 | 155 | 9 | 133 | 7 |

| 100×75×22 | 300 | 18 | 232 | 13 | 199 | 11 |

| 100×100×22 | 400 | 24 | 310 | 18 | 265 | 15 |

| 150×150×22 | 900 | 54 | 698 | 40 | 596 | 33 |

| 200×200×30 | 1600 | 95 | 1240 | 58 | 1060 | 48 |

| Dia 40×22 | 40 | 3 | 39 | 2 | 33 | 2 |

| Dia 50×22 | 70 | 4.5 | 61 | 4 | 52 | 3 |

| Dia 60×22 | 100 | 6.5 | 88 | 5 | 75 | 4 |

| Dia 70×22 | 140 | 8.8 | 119 | 7 | 102 | 6 |

| Dia 75×22 | 170 | 10 | 137 | 8 | 117 | 6.5 |

| Dia 80×22 | 200 | 11 | 156 | 9 | 133 | 7 |

| Dia 90×22 | 240 | 14 | 197 | 11 | 169 | 9 |

| Dia 100×22 | 280 | 17 | 243 | 14 | 208 | 12 |

| Dia 125×22 | 400 | 24 | 380 | 22 | 325 | 18 |

| Dia 150×22 | 700 | 38 | 548 | 32 | 468 | 26 |

| Dia 200×30 | 1240 | 67 | 973 | 56 | 832 | 46 |

Silicon Carbide Foam Advantages

- High Thermal Shock Resistance: Maintains structural integrity under rapid temperature changes during metal casting.

- Excellent Filtration Efficiency: Effectively removes inclusions and impurities from molten metals.

- High Mechanical Strength: Withstands the pressure and flow of molten metal without deformation.

- Chemical Stability: Resistant to corrosion and chemical attack from various metal alloys.

- Improved Casting Quality: Reduces turbulence and gas content, enhancing the final microstructure and strength of cast parts.

Silicon Carbide Foam Applications

- Molten Metal Filtration: Widely used in aluminum, copper, and iron casting to remove impurities and improve metal quality.

- High-Temperature Insulation: Acts as a thermal barrier in industrial furnaces and kilns due to its excellent heat resistance.

- Gas and Liquid Filtration: Serves in chemical plants and environmental systems to filter aggressive gases and corrosive liquids.

- Catalyst Support: Used in petrochemical processes as a durable and chemically stable support structure.

- Aerospace and Defense Components: Provides lightweight, strong support structures for thermal protection and vibration damping.

Silicon Carbide Foam Packaging

Silicon carbide ceramic products are typically packaged in vacuum-sealed bags to prevent moisture or contamination and wrapped with foam to cushion vibrations and impacts during transport, ensuring the quality of the products in their original condition.

Download

Get A Quote

We will check and get back to you in 24 hours.