Yttria Stabilized Zirconia Crucible

Yttria Stabilized Zirconia Crucible

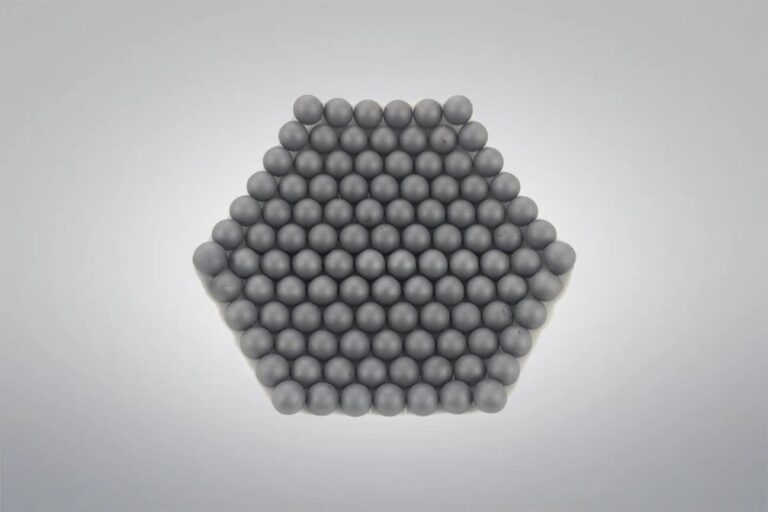

Yttria Stabilized Zirconia Crucible is a high-density ceramic designed for use up to 2000°C, ideal for melting precious and reactive metals. It offers excellent thermal shock resistance, chemical stability, and does not react with molten metals or slags. Its low thermal conductivity and high durability make it a top choice for high-temperature research and metallurgy applications. We can supply high-quality yttria stabilized zirconia crucible with various specifications and competitive prices, offering customized solutions to meet specific requirements.

Or email us at sales@heegermaterials.com.Yttria Stabilized Zirconia Crucible Data Sheet

| Color: | White |

| Density: | 5.85-6.10 g/cm3 |

| Shape: | Cylinder, Conical Cylinder, Rectangular, T-shape, or Customized according to specific drawings |

| Maximum Operating Temperature: | 2000°C |

| Dimensions: | customized |

Yttria Stabilized Zirconia Crucible Description

Yttria stabilized zirconia crucible is engineered for extreme heat environments where purity and resistance to corrosion are essential. With a melting point above 2700°C and excellent resistance to acidic and basic slags, it remains stable even when holding molten platinum, nickel, or rare earth alloys. The stabilized crystal structure ensures dimensional stability under thermal cycling, making it ideal for laboratory melting, glass formulation, and high-temperature material testing.

Yttria Stabilized Zirconia Crucible Chemical Compositions

| Composition | Content % |

| ZrO2 | 93.6 |

| MgO | 0.1 |

| CaO | 0.3 |

| Al2O3 | 0.3 |

| TiO2 | 0.1 |

| Fe2O3 | 0.1 |

| SiO2 | 0.3 |

| Y2O3 | 5.2 |

Yttria Stabilized Zirconia Crucible Features

- High-Temperature Resistance: Capable of stable performance at temperatures up to 2000°C, suitable for melting precious and reactive metals.

- Excellent Thermal Shock Resistance: Maintains structural integrity under rapid heating and cooling cycles.

- Corrosion Resistance: Withstands aggressive chemical environments, including molten salts, acids, and alkalis.

- Low Thermal Expansion: Offers dimensional stability under extreme heat, reducing the risk of cracking.

- Moisture Resistance to Molten Metals: Resists wetting and erosion by molten metals, improving lifespan and purity of melts.

Yttria Stabilized Zirconia Crucible Applications

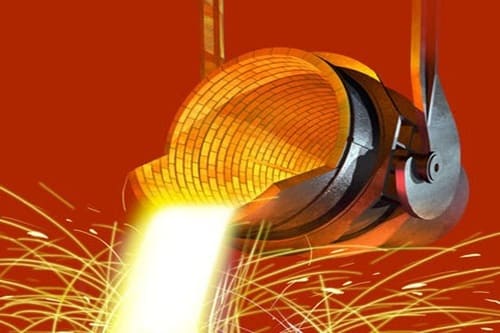

- Induction Melting Crucibles: Used for melting metals in induction furnaces due to excellent thermal stability and non-reactivity.

- High-Temperature Alloy Casting: Ideal for handling nickel-based and cobalt-based superalloys under oxidizing or vacuum atmospheres.

- Precious Metal Processing: Serves as a stable container for melting platinum and other platinum-group metals.

- Sintering of Nuclear and Electronic Materials: Applied in high-purity sintering of uranium compounds and advanced ceramics for electronics.

- Sputtering Target Preparation: Used to cast and solidify high-purity materials like magnetic alloys for hard disk drive coatings.

Yttria Stabilized Zirconia Ceramic Properties

Yttria Stabilized Zirconia Ceramic Material Machining

Yttria Stabilized Zirconia (YSZ) is a high-performance ceramic material known for its exceptional fracture toughness, high strength, and ionic conductivity. These characteristics make it ideal for demanding environments, though its machining requires specialized approaches due to its hardness and brittleness. Key machining aspects include:

- Cutting: Diamond-coated tools or precision laser cutting are employed to maintain edge integrity and minimize microcracking.

- Grinding: Fine-grit diamond grinding is used to achieve tight tolerances and smooth surfaces, especially for components with complex geometries.

- Drilling: Ultrasonic machining or precision diamond drilling enables accurate formation of micro-features for sensor and fuel cell applications.

- Surface Finishing: Polishing enhances wear resistance, biocompatibility, and thermal stability, making it suitable for advanced engineering uses.

Yttria Stabilized Zirconia Ceramic Packaging

Yttria stabilized zirconia ceramic products are typically packaged in vacuum-sealed bags to prevent moisture or contamination and wrapped with foam to cushion vibrations and impacts during transport, ensuring the quality of products in their original condition.

Download

Get A Quote

We will check and get back to you in 24 hours.