Macor Plate/Sheet/Disc

Macor Plate/Sheet/Disc

Macor Plate/Sheet/Disc is made from high-purity glass-ceramic material that can be machined with standard tools, allowing for complex shapes and tight tolerances without the need for post-firing. It offers excellent electrical insulation, dimensional stability, and can operate in vacuum environments up to 1000°C. This material is widely used in semiconductor fixtures, aerospace components, and laboratory equipment where precision, cleanliness, and thermal performance are critical. We can supply high-quality macor plate/sheet/disc with various specifications and competitive prices, offering customized solutions to meet specific requirements.

Or email us at sales@heegermaterials.com.Macor Plate/Sheet/Disc Data Sheet

| Color: | White |

| Material Composition: | Fluorphlogopite & Borosilicate Glass |

| Dimensions: | Customized |

| Processing Precision: | 0.01mm |

| Roughness: | 0.8μm |

Macor Plate/Sheet/Disc Description

Macor Plate/Sheet/Disc is a high-performance glass-ceramic known for excellent electrical insulation, resistance from -270°C to +800°C, and strong chemical stability. Its fine crystalline structure, including mica, helps stop microcracks and withstand thermal shock. With a low thermal expansion rate, it stays dimensionally stable under harsh thermal cycles, ideal for vacuum systems and precision seals. It can be machined with standard metal tools without molds or sintering, reducing lead times and costs. Widely used in aerospace, medical, scientific, and electronic vacuum systems, Macor offers a smart alternative to PTFE, alumina, or boron nitride for complex or thin-walled parts.

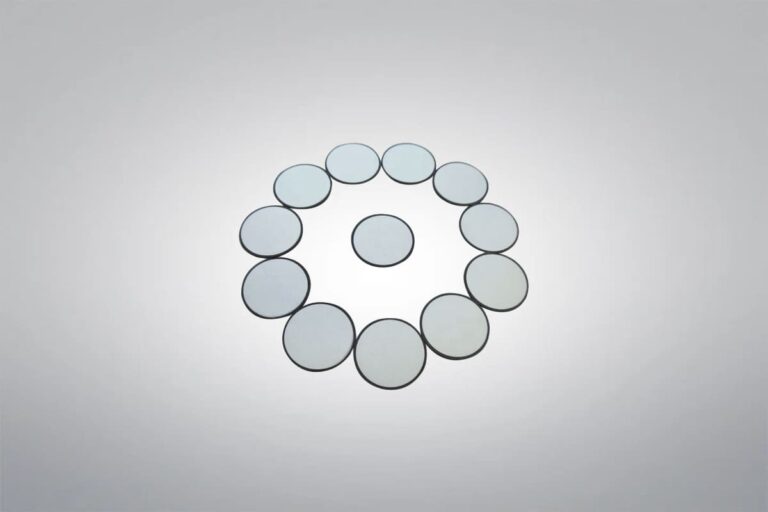

Macor Plate Macor Sheet Macor Disc

Macor Plate/Sheet/Disc Chemical Compositions

| Element / Compound | Approximate Weight (%) |

|---|---|

| Silicon (SiO₂) | 46% |

| Magnesium (MgO) | 17% |

| Aluminum (Al₂O₃) | 16% |

| Potassium (K₂O) | 10% |

| Boron (B₂O₃) | 7% |

| Fluorine (F) | 4% |

Macor Plate/Sheet/Disc Features

- Wide Temperature Range: Operates reliably from –270°C to +800°C, suitable for both cryogenic and high-temperature environments.

- Excellent Machinability: Can be machined to tight tolerances using standard metalworking tools—no sintering or post-processing required.

- Low Thermal Expansion: Offers exceptional dimensional stability, making it ideal for precision components and vacuum sealing.

- Electrical Insulation: Provides high dielectric strength and low conductivity, essential for electronic and high-voltage applications.

- Corrosion and Chemical Resistance: Inert to most acids, alkalis, and gases, ensuring long-term durability in harsh conditions.

Macor Plate/Sheet/Disc Applications

- Aerospace Insulators: Used in satellites, spacecraft, and avionics systems where thermal and electrical insulation is critical.

- Semiconductor Processing: Ideal for vacuum chambers, wafer handling tools, and components in high-purity environments.

- Medical Devices: Applied in imaging systems, surgical tools, and laboratory equipment requiring biocompatibility and precision.

- Scientific Instrumentation: Utilized in mass spectrometers, sensors, and spectrometers for its dimensional stability and low outgassing.

- High-Temperature Fixtures: Serves as supports, brackets, and mounts in furnaces, kilns, and thermal cycling equipment.

Macor Machinable Glass Ceramic Properties

Macor Machinable Glass Ceramic Material Machining

Macor is one of the rare ceramics that can be machined using standard metalworking tools without the need for post-sintering processes. This makes it especially useful for prototyping and custom part production with tight tolerances. However, understanding its machining behavior is key to achieving clean, precise results.

- Standard Tool Compatibility: Macor can be drilled, milled, turned, and tapped using regular carbide or high-speed steel tools, eliminating the need for diamond tooling.

- No Plastic Deformation: Unlike metals or plastics, Macor does not deform before breaking. Operators must prevent stress concentrations to avoid edge chipping or cracking.

- Machining Precision: Surface finishes up to 0.5 µm and tolerances as tight as ±0.005 mm are achievable with careful planning and skilled handling.

- Dry Machining Preferred: Coolants are generally not required. Dry machining helps prevent contamination and simplifies cleanup in high-purity applications.

- Practice Recommended: Due to Macor’s unique cutting behavior, it’s recommended to practice machining techniques on scrap material before processing final components.

Macor Machinable Glass Ceramic Packaging

Macor machinable glass ceramic products are typically packaged in vacuum-sealed bags to prevent moisture or contamination and wrapped with foam to cushion vibrations and impacts during transport, ensuring the quality of products in their original condition.

Download

Get A Quote

We will check and get back to you in 24 hours.