Zirconia Toughened Alumina Plate/Sheet/Disc

Zirconia Toughened Alumina Plate/Sheet/Disc

Zirconia Toughened Alumina Plate/Sheet/Disc offers a reliable balance of strength, hardness, and fracture resistance. Designed for demanding applications, these ceramic components perform well under mechanical load and high temperatures. They’re widely used in wear plates, thermal shields, and electronic insulation. We can supply high-quality zirconia toughened alumina plate/sheet/disc with various specifications and competitive prices, offering customized solutions to meet specific requirements.

Or email us at sales@heegermaterials.com.Zirconia Toughened Alumina Plate/Sheet/Disc Data Sheet

| Composition: | Alumina/Zirconia |

| Color: | White or off white |

| Dimensions: | Customized |

Zirconia Toughened Alumina Plate/Sheet/Disc Description

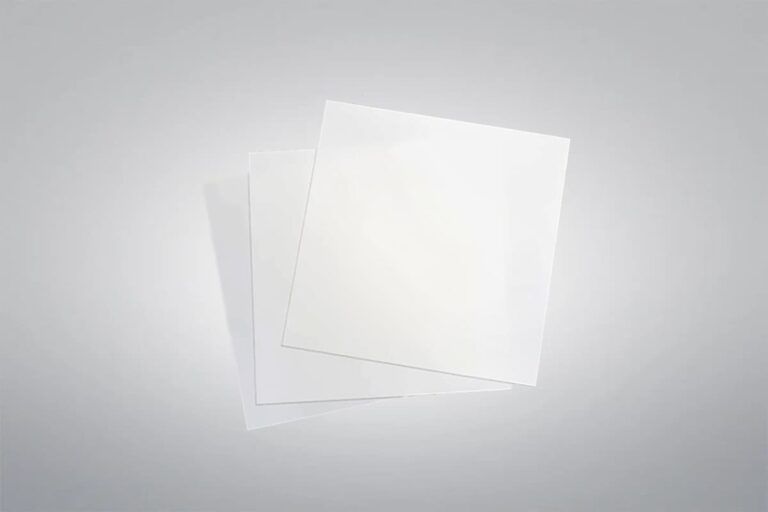

Zirconia toughened alumina plate/sheet/disc combines the hardness and stability of alumina with the toughness of zirconia, resulting in strong, durable ceramic components. These plates, sheets, and discs exhibit excellent resistance to wear, thermal shock, and mechanical stress, making them suitable for high-temperature and high-load environments. Commonly used in electronic substrates, protective armor, precision fixtures, and industrial insulation systems, they maintain stable dimensions and surface quality even under demanding conditions.

Zirconia Toughened Alumina Sheet Zirconia Toughened Alumina Plate Zirconia Toughened Alumina Disc

Zirconia Toughened Alumina Plate/Sheet/Disc Features

- High fracture toughness: Resists cracking and chipping under stress.

- Excellent surface quality: Smooth finish supports precision applications and easy integration.

- Outstanding thermal stability: Maintains structure and performance under high temperatures.

- Superior wear resistance: Withstands friction and abrasion in harsh environments.

- Stable mechanical properties: Delivers consistent strength and dimensional reliability over time.

Zirconia Toughened Alumina Plate/Sheet/Disc Applications

- Precision fixtures and jigs: Used in high-precision machining and measurement systems requiring stable, wear-resistant platforms.

- Electronic insulation layers: Act as a dielectric barrier in high-voltage or high-frequency electronic equipment.

- Thermal barrier components: Serve as a protective layer in furnaces, kilns, or heat-processing equipment.

- Wear-resistant liners and covers: Applied in industrial systems exposed to friction, erosion, or impact.

- Protective ceramic armor panels: Utilized in personal and equipment protection where strength and fracture resistance are critical.

Zirconia Toughened Alumina Material Properties

Zirconia Toughened Alumina Material Grades

CeramAlloy ZTA is a high performance ceramic composite and a unique ceramic material by way of exhibiting a combination of high hardness, strength, wear and corrosion resistance resulting from its Alumina content, while still maintaining reasonably high fracture toughness resulting from its Zirconia content.

Applications:

- High pressure equipment – ball valve balls and seats

- Rollers and guides for metal forming

- Thread and wire guides

- Deep well down-hole valves and seats

- Shaft bearings/bushings

Ultra Hard is a high performance ceramic composite and a unique ceramic material by way of exhibiting a combination of high hardness, strength, wear and corrosion resistance resulting from its Alumina content, while still maintaining reasonably high fracture toughness resulting from its Zirconia content.

Applications:

- High pressure equipment – ball valve balls and seats – particularly suitable for high flow/abrasive fluids

- Focusing nozzles for abrasive media

- Ultra high pressure pumping elements

- Deep well down-hole valves and seats

- Rollers and guides for metal forming

- Thread and wire guides

- Metal extrusion dies

Zirconia Toughened Alumina Ceramic Machining

Zirconia Toughened Alumina (ZTA) is a high-performance composite material that enhances toughness and strength by incorporating zirconia (ZrO₂) into alumina (Al₂O₃). Machining this material requires addressing its high hardness and brittleness. Key machining aspects include:

- Cutting: Utilizes diamond tools or laser cutting for precision and edge integrity.

- Grinding: Employs precision grinding to control surface roughness and dimensional tolerances.

- Drilling: Uses ultrasonic or diamond drills for micro-holes, ideal for electronic applications.

- Surface Finishing: Polishing or coating improves wear resistance and aesthetics.

ZTA machining is widely applied in precision component manufacturing, such as electronic substrates and medical implants.

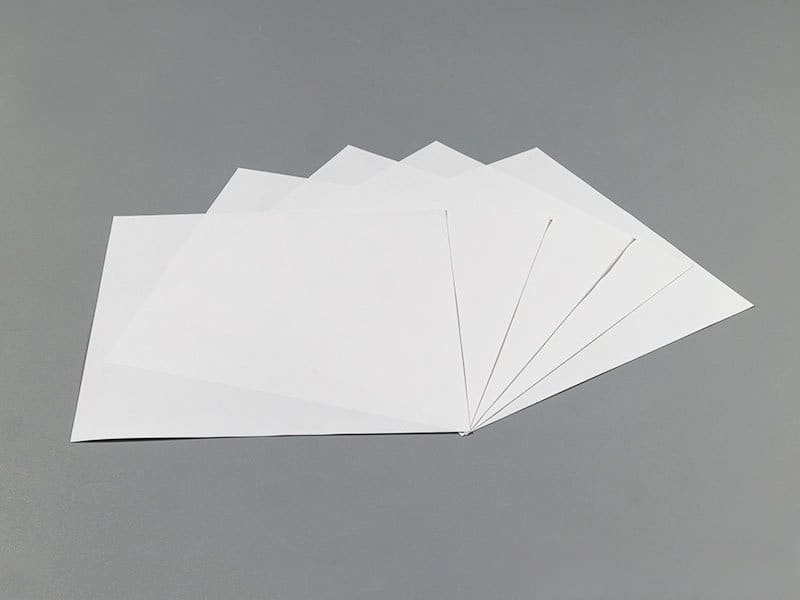

Zirconia Toughened Alumina Ceramic Packaging

Zirconia Toughened Alumina Ceramic products are typically packaged in vacuum-sealed bags to prevent moisture or contamination and wrapped with foam to cushion vibrations and impacts during transport, ensuring the quality of products in their original condition.

Download

Get A Quote

We will check and get back to you in 24 hours.