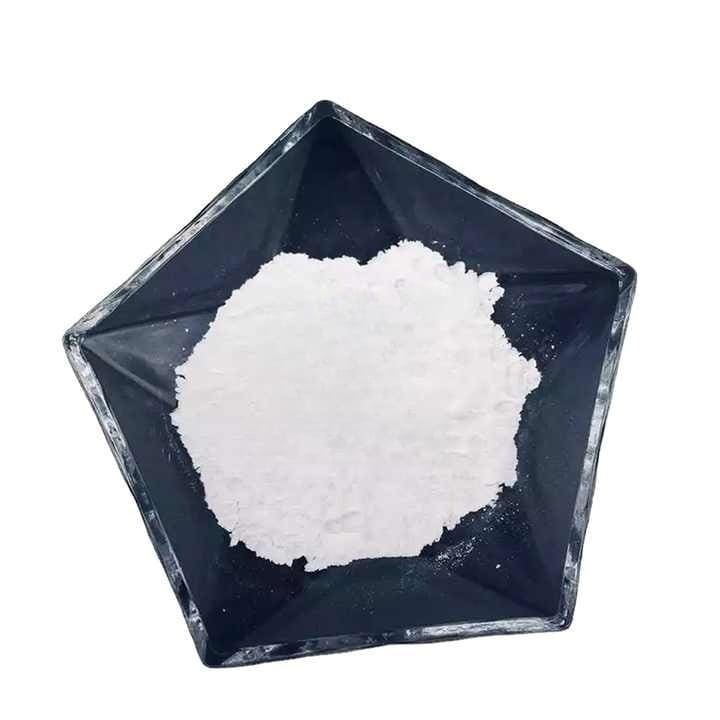

Zirconia Toughened Alumina Powder

Zirconia Toughened Alumina Powder

Particle Size: 0.6-1.0 μm

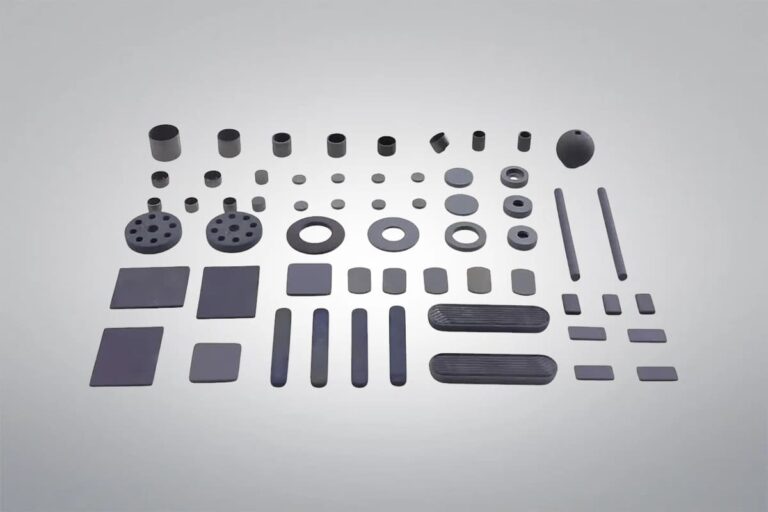

Zirconia Toughened Alumina Powder is a fine white ceramic powder known for its balanced mechanical strength and ease of sintering. It forms dense, smooth-surfaced ceramics with excellent machinability and durability. This material is widely used in high-performance applications such as ceramic bases, precision molds, valve parts, and wear-resistant components. We can supply high-quality zirconia toughened alumina powder with various specifications and competitive prices, offering customized solutions to meet specific requirements.

Zirconia Toughened Alumina Powder Data Sheet

| Composition: | Alumina/Zirconia |

| Color: | White or off white |

| Dimensions: | Customized |

| Shape: | Powder |

Zirconia Toughened Alumina Powder Description

Zirconia toughened alumina powder is a white ceramic powder featuring low sintering temperature and uniform dispersion of both phases. After firing, the green body is easy to machine and offers a smooth surface finish. The final ceramic products are lightweight, strong, tough, and highly resistant to wear, corrosion, and high temperatures. This powder is widely used as a raw material for structural ceramic parts, including cutting tool bases, molds, wear-resistant bushings, valve seats, pump components, and textile machinery parts.

Zirconia Toughened Alumina Powder Specifications

| ZrO₂(HfO₂) + Y₂O₃ | 19-21 wt% |

| Al₂O₃ | 78-80 wt% |

| Cl⁻ | 0.01 wt% |

| Fe₂O₃ | 0.003 wt% |

| BET Surface Area | 8-10 m²/g |

| D50 Particle Size | 0.6-1.0 μm |

| Other Impurities (Si, Fe, etc.) | Controlled below 100 ppm |

| Suggested Forming Method | Dry Pressing & Isostatic Pressing |

| Recommended Sintering Temperature | 1420-1450℃ |

| Flexural Strength | >550 MPa |

| Sintered Density | >4.2 g/cm³ |

| Customizable | Binder addition is possible upon request |

Zirconia Toughened Alumina Powder Features

- White appearance: Fine white powder with clean, consistent texture.

- Low sintering temperature: Enables energy-efficient processing and dense ceramic formation.

- Uniform phase distribution: Ensures stable mechanical properties and reliable performance.

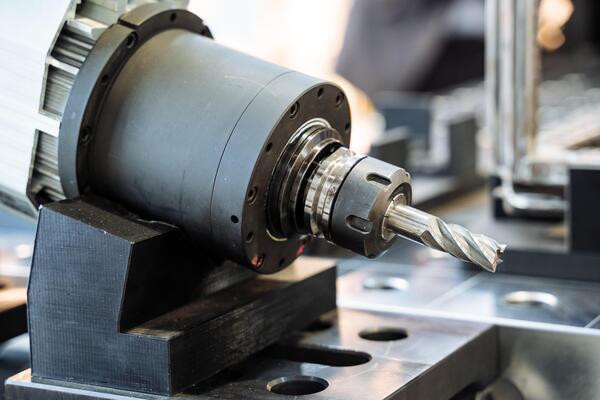

- Good green machinability: Fired bodies are easy to process with excellent surface quality.

- Enhanced final properties: Yields ceramics with low density, high strength, toughness, wear resistance, and thermal stability.

Zirconia Toughened Alumina Powder Applications

- Cutting tool bases: Used to produce tough, wear-resistant ceramic substrates for cutting tools.

- Precision molds: Ideal for high-strength, corrosion-resistant ceramic mold components.

- Wear-resistant bushings: Applied in machinery to reduce abrasion and extend service life.

- Valve seats and pump parts: Suitable for demanding fluid-handling environments requiring thermal and chemical stability.

- Aerospace components: Suitable for structural parts exposed to extreme temperatures and stress cycles.

Zirconia Toughened Alumina Material Properties

Zirconia Toughened Alumina Material Grades

CeramAlloy ZTA is a high performance ceramic composite and a unique ceramic material by way of exhibiting a combination of high hardness, strength, wear and corrosion resistance resulting from its Alumina content, while still maintaining reasonably high fracture toughness resulting from its Zirconia content.

Applications:

- High pressure equipment – ball valve balls and seats

- Rollers and guides for metal forming

- Thread and wire guides

- Deep well down-hole valves and seats

- Shaft bearings/bushings

Ultra Hard is a high performance ceramic composite and a unique ceramic material by way of exhibiting a combination of high hardness, strength, wear and corrosion resistance resulting from its Alumina content, while still maintaining reasonably high fracture toughness resulting from its Zirconia content.

Applications:

- High pressure equipment – ball valve balls and seats – particularly suitable for high flow/abrasive fluids

- Focusing nozzles for abrasive media

- Ultra high pressure pumping elements

- Deep well down-hole valves and seats

- Rollers and guides for metal forming

- Thread and wire guides

- Metal extrusion dies

Zirconia Toughened Alumina Powder Packaging

The zirconia toughened alumina powder is typically packaged in sealed, moisture-proof plastic bags, then placed in sturdy drum containers or fiber cartons to prevent contamination and ensure safe transport. Standard packaging sizes include 1 kg, 5 kg, and 10 kg options, with custom packaging available upon request to meet specific usage or storage needs.

Download

Get A Quote

We will check and get back to you in 24 hours.