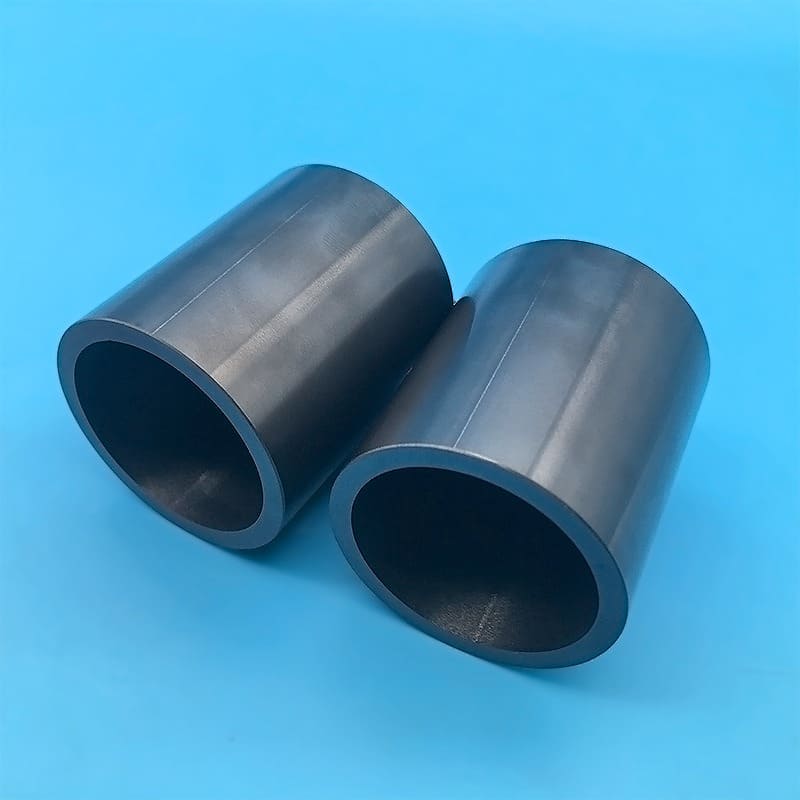

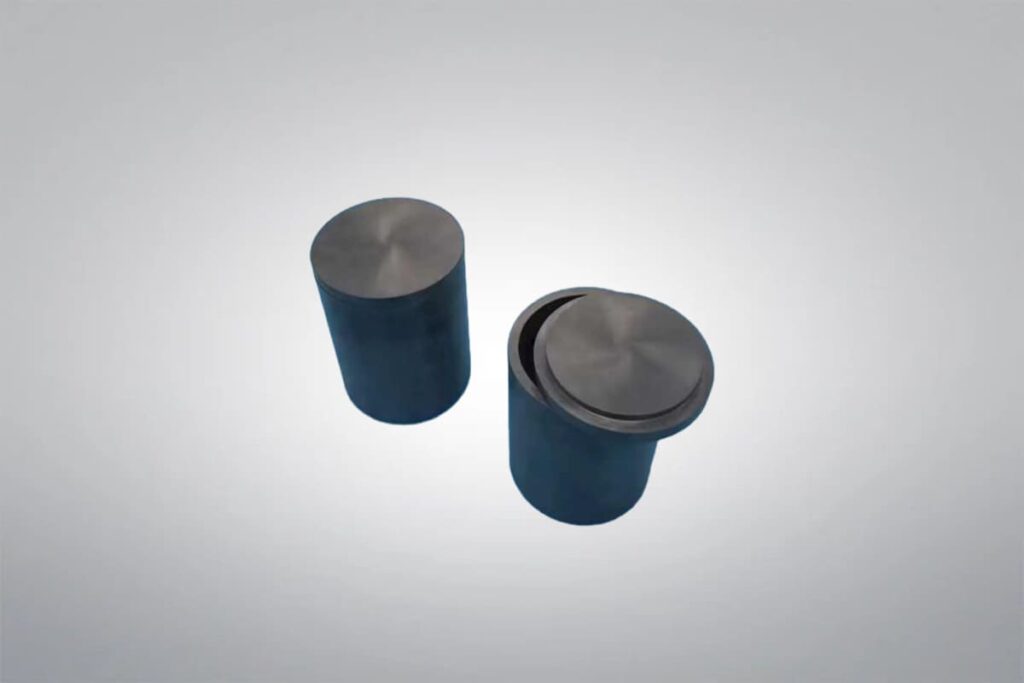

Silicon Nitride Crucible

Silicon Nitride Crucible

Purity: ≥99%

Silicon Nitride Crucible offers outstanding thermal shock resistance, high mechanical strength, and excellent chemical stability. It resists corrosion from acids and weak alkalis, and remains stable in contact with molten metals such as zinc, aluminum, and silver. Its dense structure and smooth surface make it suitable for use in demanding environments like metal processing and chemical experiments. We can supply high-quality silicon nitride crucibles with various specifications and competitive prices, offering customized solutions to meet specific requirements.

Or email us at sales@heegermaterials.com.Silicon Nitride Crucible Data Sheet

| Reference Code: | HM2559 |

| Purity: | ≥99% |

| Color: | Black |

| Chemical Formula: | Si3N4 |

| Material Grades: | HMSN1000, HMSN2000, HMSN3000, HMSN4000 |

| Density: | 3.20 g/cm3 |

| Dimension: | customized |

| Shape: | Cylinder, Conical Cylinder, Rectangular, T-shape, or customized. |

Silicon Nitride Crucible Description

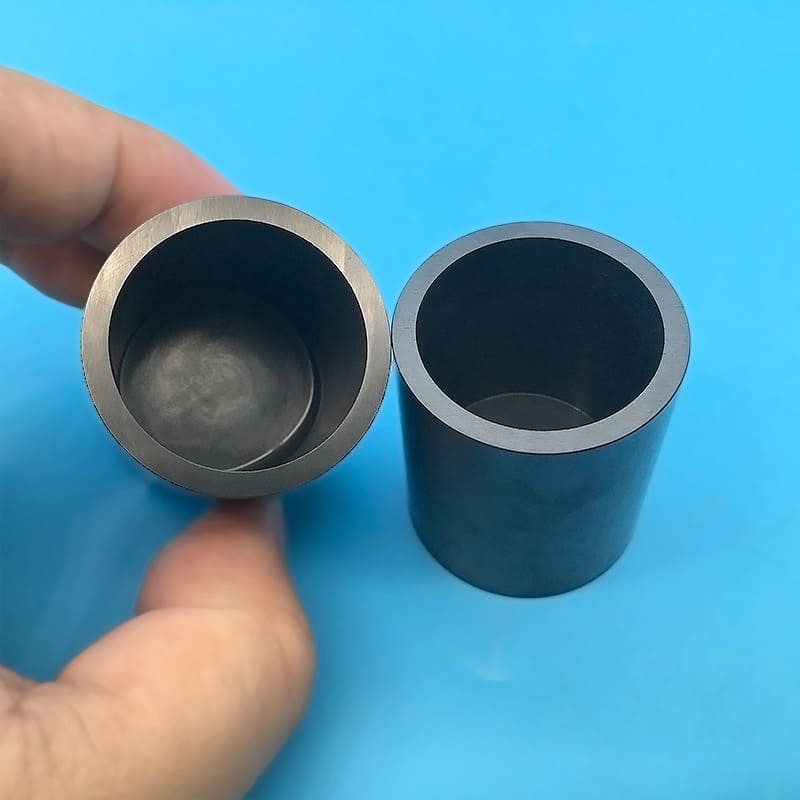

Silicon Nitride Crucible is engineered from high-purity Si₃N₄ ceramic, offering strong resistance to chemical attack and mechanical stress. Its non-reactive surface prevents sticking or contamination from molten metals, while its dense structure provides excellent durability during repeated thermal cycling. Widely used in labs and industrial setups, it’s especially effective for melting or handling alloys and corrosive materials. With a smooth interior and consistent wall thickness, this crucible ensures stable performance and easy maintenance throughout demanding processes.

Silicon Nitride Crucible Features

- Excellent Thermal Stability: Capable of withstanding rapid temperature changes without cracking, ensuring reliable performance in high-heat environments.

- Exceptional Corrosion Resistance: Resistant to a wide range of acids and bases, making it ideal for use in harsh chemical processing and metal melting.

- High Physical Strength: Offers superior strength with high bending (600 MPa) and compressive (2500 MPa) strength, maintaining its shape and functionality under mechanical stress.

- Robust Heat Shock Resistance: Withstands extreme temperature fluctuations (△T℃ of 500), making it suitable for rapid heating and cooling cycles.

- Advanced Structural Design: Engineered with specific shapes like center holes to enhance versatility and adapt to various experimental setups.

Silicon Nitride Crucible Applications

- Laboratory Research: Widely used in chemical and physical laboratories for high-temperature chemical analysis and material science experiments.

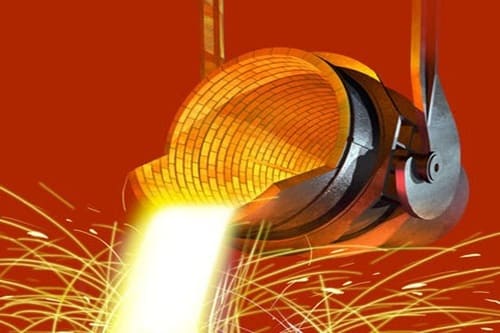

- Industrial Melting: Utilized in metal processing and ceramic manufacturing for melting metals and other high-melting-point materials.

- High-Temperature Furnace Applications: Employed as melting containers in high-temperature furnaces for processing materials like glass or specialty alloys.

- Chemical Equipment: Used as reaction vessels in chemical production, especially for processes requiring extreme temperatures and chemical stability.

- Metal Alloy Processing: Ideal for handling molten metal alloys, providing superior durability and corrosion resistance during metal casting and alloying processes.

Silicon Nitride Material Properties

Silicon Nitride Material Grades

HMSN1000 is produced through a gas over-pressure sintering technique, which is widely recognized for enabling the manufacture of high-strength silicon nitride parts with intricate shapes. The process starts with a silicon nitride powder blend that includes sintering additives—such as yttria, magnesium oxide, or alumina—to create a liquid phase during sintering, as well as binders to enhance the structural integrity of the pre-sintered form. After shaping the powder into the desired geometry and performing any necessary green machining, the components are densified in a nitrogen-pressurized furnace. This environment ensures proper consolidation while minimizing material loss due to evaporation or decomposition of silicon, nitrogen, and the additive elements.

Common Uses

- Components for aerospace systems

- Rolling and sliding elements in bearing units

- High-durability parts for internal combustion engines

- Tools and accessories for casting and metal processing

- Structural parts in mechanical assemblies

- Biocompatible elements for medical devices

HMSN2000 is manufactured using a hot pressing technique, where silicon nitride powder is compacted under high pressure and elevated temperature simultaneously. This method relies on specialized equipment, including precision dies and uniaxial presses. The result is a dense ceramic with outstanding strength and durability. However, the process is best suited for forming basic geometries due to the limitations of the equipment. Since components cannot be machined in the pre-sintered (green) state, all post-processing must be done through diamond grinding, which is both time-consuming and costly. As a result, this method is generally reserved for small-scale production of straightforward parts where premium material performance is required.

Common Uses

- Structural parts in aircraft and spacecraft systems

- Equipment and piping components in chemical processing industries

- Friction-resistant elements for engines

- Tools and wear parts used in metal casting environments

- Load-bearing and precision parts in industrial machinery

- Specialized pieces in medical and dental instruments

HMSN3000 utilizes the Hot Isostatic Pressing (HIP) process, where silicon nitride powder is compacted under both high pressure and high temperature. The material is placed in a chamber that is pressurized with inert gas, subjecting the component to uniform pressure from all sides at up to 2000 bar while it is simultaneously heated. This method helps to remove any residual porosity or defects during the sintering process, resulting in a material with a density close to its theoretical maximum. While HIP significantly improves the mechanical properties, durability, and overall reliability of the material, the high cost and complexity of the process limit its use to highly specialized applications.

Common Uses

- Components for aerospace and defense industries

- Precision bearing applications, especially in high-performance environments

- Equipment and components in chemical processing and industrial plants

- Engine parts subjected to extreme wear and thermal stress

- Foundry tools and wear-resistant components

- High-performance parts for mechanical engineering systems

- Medical components requiring high strength and biocompatibility

HMSN4000 is produced through an extruded gas over-pressure sintering process, where silicon nitride powder is blended with sintering additives, such as yttria, magnesium oxide, and/or alumina, to facilitate liquid-phase sintering. Additionally, binders are incorporated to enhance the mechanical properties of the green ceramic structure. The extrusion process helps form the material into the desired shape, and the parts are then subjected to gas over-pressure sintering in a controlled environment. This method ensures uniform density and superior mechanical performance, making it ideal for high-performance applications.

Common Uses

- Aerospace industry components

- Bearings used in high-performance machinery

- Equipment for chemical plants and industrial processing

- Wear-resistant parts for engines

- Components used in foundry operations

- Parts for mechanical engineering systems

- Medical-grade components for high-precision instruments

Silicon Nitride Ceramic Machining

Silicon nitride can be machined in green, biscuit, or fully sintered forms, each with different machining properties. In green or biscuit states, it is easier to shape into complex forms, but the material shrinks about 20% during sintering, affecting dimensional accuracy. For tight tolerances, fully sintered silicon nitride must be machined using diamond tools, a precise but costly process due to the material’s hardness and toughness.

Machining Methods and Considerations:

- Green or Biscuit Machining: Easier to machine into complex shapes but lacks final dimensional accuracy.

- Sintering Shrinkage: The material shrinks approximately 20% during the sintering process, affecting post-sintering dimensions.

- Tight Tolerances: For precise dimensions, post-sintered material must be machined using diamond tools.

- Diamond Grinding: This technique involves the use of diamond-coated tools or wheels to abrade the material and achieve the desired shape.

- Cost and Time: Machining fully dense silicon nitride is a slow, expensive process due to the hardness and toughness of the material.

Silicon Nitride Ceramic Packaging

Silicon nitride ceramic products are typically packaged in vacuum-sealed bags to prevent moisture or contamination and wrapped with foam to cushion vibrations and impacts during transport, ensuring the quality of products in their original condition.

Download

Get A Quote

We will check and get back to you in 24 hours.