Zirconia Foam

Zirconia Foam

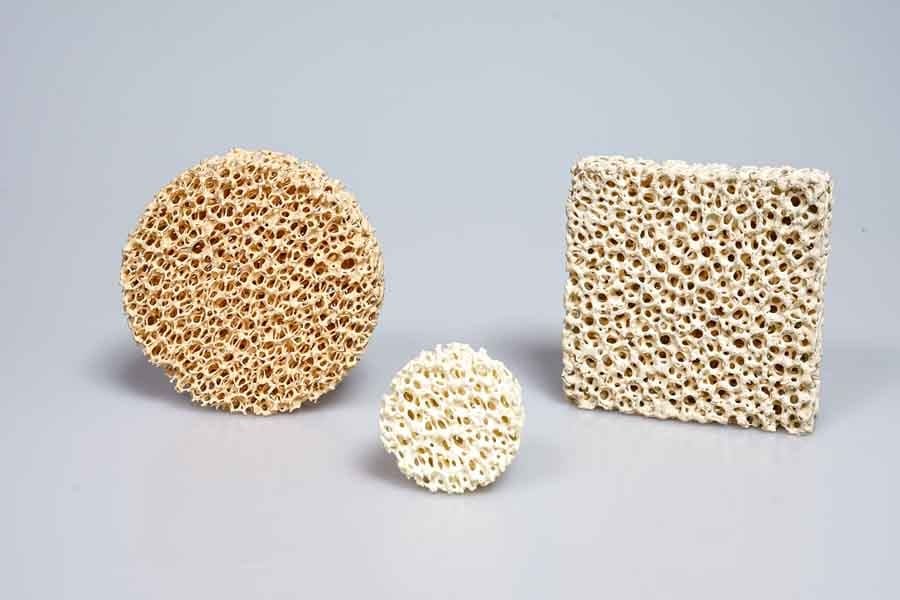

Zirconia Foam is a high-performance ceramic material known for its excellent thermal stability, corrosion resistance, and low thermal conductivity. It’s widely used in high-temperature filtration, thermal insulation, and catalyst support applications due to its porous structure and durability. we can supply high-quality zirconia foam with various specifications and competitive prices, offering customized solutions to meet specific requirements.

Or email us at sales@heegermaterials.com.Zirconia Foam Data Sheet

| Chemical Composition | ZrO2, SiO2 |

| Porosity (%) | 80–90% |

| Pore Density (PPI) | 8–45 |

| Operating Temperature (°C) | ≤1100°C |

| Room Temperature Bending Strength (MPa) | 1.0 MPa |

| Room Temperature Compression Strength (MPa) | 1.2 MPa |

| Thermal Shock Resistance | 1100°C to room temperature, 6 times |

| Bulk Density (g/cm³) | 0.4–0.5 g/cm³ |

| Suitable Alloys | Alloy steel and other high-melting-point metal alloys |

Zirconia Foam Description

Zirconia Foam is a high-performance porous ceramic material engineered for extreme-temperature filtration and insulation applications. Manufactured using high-purity zirconia, it withstands continuous use in environments reaching up to 1700°C, making it ideal for filtering molten stainless steel, carbon steel, and large iron castings. Its 3D interconnected pore structure enables excellent removal of non-metallic inclusions and refines molten metal flow by converting turbulent streams into uniform laminar flow. This not only enhances casting surface quality but also minimizes internal defects and lowers rejection rates. Thanks to its high thermal shock resistance, mechanical strength, and chemical inertness, zirconia foam is the preferred choice for advanced foundries, metallurgical processing, and other high-temperature applications requiring precision and reliability.

Zirconia Foam Stock Specifications

| Shape And Size (mm) | Circular | Φ50×22, Φ60×22, Φ70×22, Φ75×25, Φ100×25, Φ125×30, Φ150×30, Φ200×35, Φ250×40, Φ300×40 |

| Square | 50×50×22, 60×60×22, 70×70×22, 75×75×25, 100×100×25, 125×125×25, 150×150×30, 175×175×35, 200×200×35, 250×250×40 | |

| Custom Dimensions | Sizes can be customized to specific requirements. | |

| Edge Wrapping | Filters can be wrapped with high-temperature fiber cotton of thickness 1mm, 3mm, or 5mm. Ceramic-edge products can also be customized. Maximum diameter/length can reach up to 300mm. | |

Zirconia Foam Filtration Capacity

| Dimensions (mm) | Flow Rate (kg/s) (Carbon Steel) | Flow Rate (kg/s) (Alloy Steel) | Filter Capacity (kg) |

|---|---|---|---|

| 40×40×20 | 2 | 2.5 | 32 |

| 50×50×22 | 3 | 4 | 50 |

| 55×55×22 | 4 | 5 | 55 |

| 60×60×22 | 3 | 4 | 70 |

| 75×75×25 | 5 | 6.5 | 105 |

| 100×100×25 | 7 | 10 | 190 |

| 150×150×30 | 17 | 22 | 420 |

| Dia 50×22 | 2 | 3 | 40 |

| Dia 60×25 | 2 | 3.5 | 50 |

| Dia 70×25 | 3 | 4.2 | 70 |

| Dia 90×25 | 6 | 8 | 115 |

| Dia 100×25 | 7 | 9 | 145 |

| Dia 120×25 | 11 | 14 | 210 |

| Dia 150×30 | 12.5 | 15 | 330 |

Zirconia Foam Usage Guides

- Pore Size Selection: For medium and large steel castings, filters with 10–15 PPI are recommended. For smaller castings with higher requirements, filters with smaller pore sizes can be selected based on specific needs.

- Filtration Capacity: Carbon steel and low-alloy steel: 1.0–2.7 kg/cm², Stainless steel: 1.0–4.0 kg/cm²

- Filtration capacity is influenced by casting type, placement position, pouring temperature, pressure head size, and other conditions. For detailed usage guidelines, please contact us for more details.

Zirconia Foam Advantages

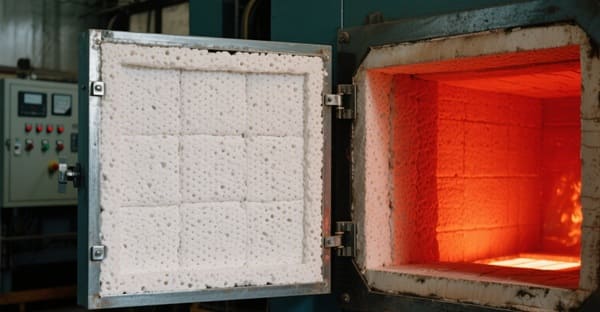

- Excellent Thermal Stability: Maintains structural integrity at extreme temperatures, making it suitable for high-heat environments.

- High Corrosion Resistance: Withstands aggressive chemical environments, including acids and molten metals.

- Low Thermal Conductivity: Provides outstanding insulation properties for energy-efficient systems.

- High Mechanical Strength: Despite its porous nature, zirconia foam offers good strength and durability.

- Chemical Inertness: Minimizes reaction with surrounding materials, ideal for sensitive processes like filtration and catalysis.

Zirconia Foam Applications

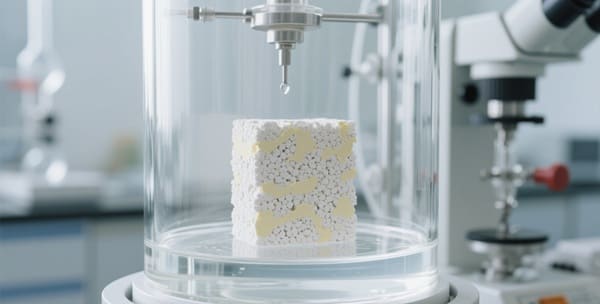

- High-Temperature Filtration: Zirconia foam is used in molten metal filtration, especially for steel and alloys, due to its excellent thermal stability and corrosion resistance.

- Catalyst Support: Its high surface area and chemical inertness make it an effective support material for catalysts in chemical reactions and fuel cells.

- Thermal Insulation: Zirconia foam serves as an insulating material in furnaces and kilns, capable of withstanding extreme heat without degradation.

- Biomedical Applications: Biocompatible and stable, zirconia foam is applied in bone scaffolding and dental implants in regenerative medicine.

- Gas Diffusion Layers: In solid oxide fuel cells (SOFCs), zirconia foam is used to distribute gases evenly and enhance electrochemical performance.

Zirconia Foam Packaging

Zirconia foam products are typically packaged in vacuum-sealed bags to prevent moisture or contamination and wrapped with foam to cushion vibrations and impacts during transport, ensuring the quality of the products in their original condition.

Download

Get A Quote

We will check and get back to you in 24 hours.