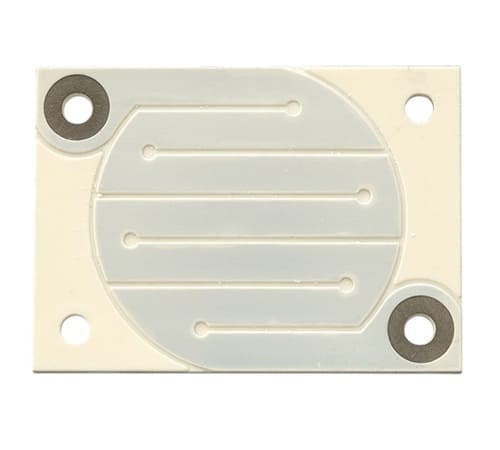

Pyrolytic Boron Nitride Heater

Pyrolytic Boron Nitride Heater

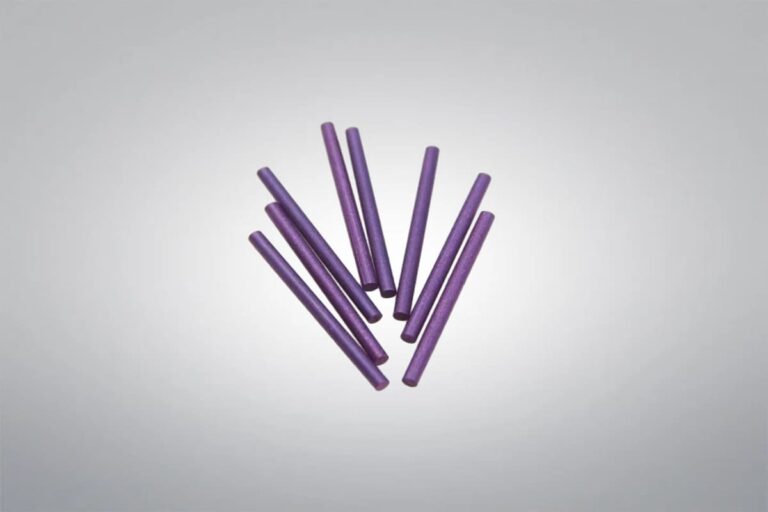

Material: PBN-PG-PBN

Diameter: 0.5-5 inch

Pyrolytic Boron Nitride Heater is a high-performance heating element for high-temperature, high-vacuum, and high-purity processes. Constructed with a pyrolytic boron nitride (PBN) substrate and apyrolytic graphite (PG) conductive heating layer, it is produced via chemical vapor deposition (CVD). As a leading supplier and manufacturer of premium pyrolytic boron nitride products, we can supply high-quality PBN/PG heaters with various specifications and competitive prices, offering customized solutions to meet specific requirements.

Or email us at sales@heegermaterials.com.Pyrolytic Boron Nitride Heater Data Sheet

| Reference: | PBN1277 |

| Material: | PBN-PG-PBN |

| Purity: | 99.99%-99.999% |

| Diameter: | 0.5-5 inch |

| Density: | 1.95-2.20 g/cm3 |

| Production Method: | CVD |

Pyrolytic Boron Nitride Heater

Pyrolytic Boron Nitride Heater combines three layers of ultra-high purity ceramics (PBN-PG-PBN), to produce an advanced ceramic heating element system. Pyrolytic Boron Nitride (PBN) serves as the insulating substrate, while Pyrolytic Graphite (PG) acts as the conductive heating layer. It is manufactured through high-temperature chemical vapor deposition (CVD) technology. It features excellent thermal uniformity, thermal shock resistance, and chemical stability. It is capable of reaching temperatures above 1600 ℃ in minimal time. Advanced Ceramics Hub can supply customized solutions for dimension, shape, operating temperature, current, and voltage specifications to meet diverse industrial and research requirements.

Pyrolytic Boron Nitride Heater Specifications

| Diameter: | 0.5 -5 inch |

| Power output: | 150-3000W |

| Max operating temperature: | PBN: 1700 ℃, PG: 1600 ℃ |

Pyrolytic Boron Nitride Heater Advantages

- Excellent high-temperature performance: It can operate stably above 1600 ℃.

- High purity and contamination-free: No gas release at high temperatures.

- Thermal uniformity: It can deliver consistent temperature distribution, minimizing process variations caused by thermal gradients.

- Thermal shock resistance: It can withstand rapid heating and cooling cycles without cracking or damage.

- Chemical stability: It is chemically inert to nearly all metals, liquids, and gases.

- Fast response time: It heats up quickly.

- Highly customizable: It allows flexible design in shapes, dimensions, and thermal gradients to meet specific requirements.

Pyrolytic Boron Nitride Heater Applications

- Semiconductor Manufacturing: PBN/PG Heaters are employed in wafer annealing, thin film deposition, and doping processes, offering a clean and uniform heating environment.

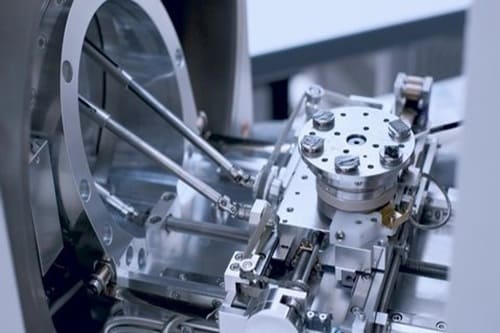

- Molecular Beam Epitaxy (MBE): PBN/PG Heaters can be used under ultra-high vacuum conditions to grow high-quality single-crystal films, such as III-V compound semiconductors.

- Thin Film Deposition: PBN/PG Heaters support physical vapor deposition (PVD) and chemical vapor deposition (CVD) processes, ensuring material purity and structural integrity.

- Superconducting Materials Research: PBN/PG Heaters provide precise high-temperature control for preparing superconducting films and devices.

- Metal Evaporation: PBN/PG Heaters can heat metal sources in vacuum evaporation systems for coating or alloy production.

- High-Temperature Experiments: PBN/PG Heaters can be utilized in research to test material thermal properties or conduct high-temperature chemical reactions.

- Optoelectronic Device Fabrication: PBN/PG Heaters can supply a stable high-temperature environment for growing components like lasers and LEDs.

Pyrolytic Boron Nitride Material Properties

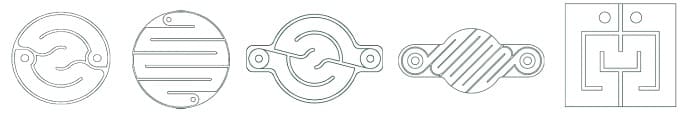

Pyrolytic Boron Nitride Machining

The Advanced Ceramic Hub machining center is equipped with multiple CNC lathes and CNC milling machines, and it is backed by extensive machining experience. We offer customized pyrolytic boron nitride ceramic products and profiles with extremely tight tolerances, tailored to customer requirements. During the machining process, the following precautions should be observed:

- Pyrolytic boron nitride ceramic materials can be machined using standard high-speed steel cutting tools. For harder and composite materials, carbide or diamond tools are recommended.

- Grinding operations can be performed as needed, and standard taps and dies can be used to machine threads.

- The machining process should always be kept dry, with no need for cutting oils or coolants.

- Cutting tools should be sharp and clean, and tools with negative rake angles should not be used.

- Care should be taken when clamping and securing materials to avoid applying excessive pressure. Climb milling techniques should be used to prevent edge and corner chipping.

Pyrolytic Boron Nitride Packaging

Pyrolytic Boron Nitride Ceramic products are typically packaged in vacuum-sealed bags to prevent moisture or contamination, and wrapped with foam to cushion vibrations and impacts during transport, ensuring the quality of products in their original condition.

Download

Get A Quote

We will check and get back to you in 24 hours.