Boron Nitride Modified Platelet Powder

Boron Nitride Modified Platelet Powder

Purity: 99% or 99.5%

Particle Size: 0.5 μm, 1-2 μm, 3-5 μm, 5-10 μm, 10-15 μm, 15-20 μm, 20-30 μm, or customized

Boron Nitride Modified Platelet Powder is a high-performance ceramic material with excellent thermal resistance, chemical stability, superior lubricity, and electrical insulation. It undergoes various surface modification treatments to meet specific requirements. As a leading supplier and manufacturer of premium boron nitride products, we can supply high-quality boron nitride modified platelet powders with various specifications and competitive prices, offering customized solutions to meet specific requirements.

Or email us at sales@heegermaterials.com.Boron Nitride Modified Platelet Powder Data Sheet

| Reference: | HM1971 |

| CAS: | 10043-11-5 |

| Purity: | 99% or 99.5% |

| Particle Size: | 0.5 μm, 1-2 μm, 3-5 μm, 5-10 μm, 10-15 μm, 15-20 μm, 20-30 μm, or customized according to specific requirements. |

| Color: | White |

| Melting Point: | 2937 ℃ |

| Density: | 1.9-2.2 g/cm3 |

| Dielectric Constant: | 4.3 |

| Dielectric Strength: | 80 kV/mm |

| Thermal Conductivity: | 300 W/mK |

Boron Nitride Modified Platelet Powder

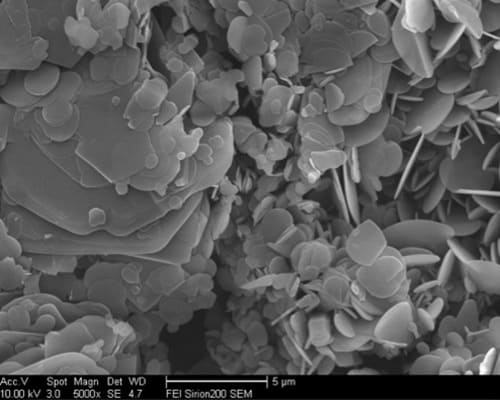

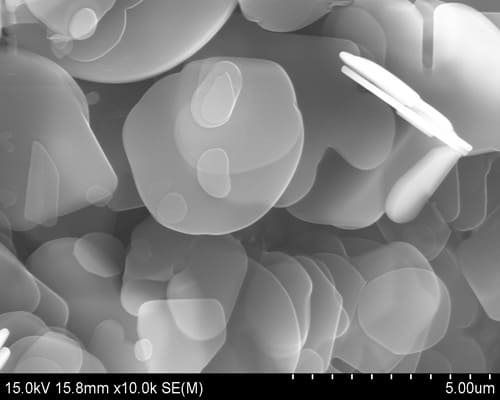

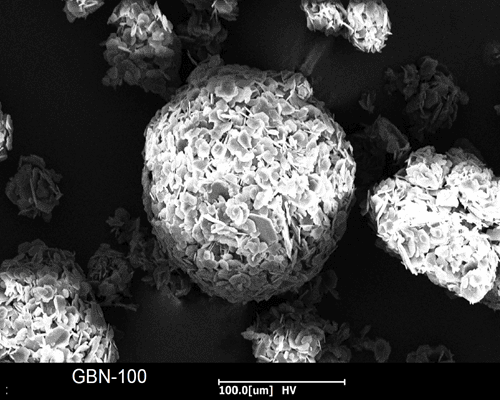

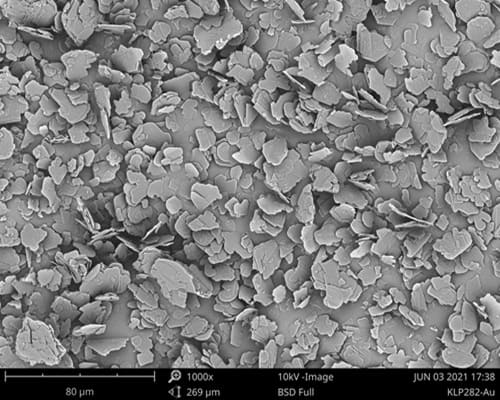

Boron Nitride Modified Platelet Powder is a white loose powder made of high-purity crystalline boron nitride flakes through various surface modifications. It effectively increases the filler content of boron nitride in the system and enables efficient packing of boron nitride particles, resulting in multidirectional and continuous heat conduction. This reduces the thermal interface resistance between the substrate and filler, leading to a significant thermal efficiency. Advanced Ceramics Hub can also supply boron nitride products with high-purity and different additives based on specific requirements.

Boron Nitride Modified Platelet Powder Specifications

Boron Nitride Powder Fine Particle Solutions

Modified Platelet Powder

BN Modified Platelet Powder can be customized using various surface modifications according to specific requirements. The modified powder effectively improve the filling capacity.

Boron Nitride Modified Platelet Powder Advantages

- High thermal conductivity

- Low thermal expansion coefficient

- Low dielectric constant

- Low ionic content

- Low friction coefficient, good lubrication at high temperatures, excellent compressive and wear resistance

- Various surface modifications, including hydrophilic and oleophilic treatments

- Non-wetting and non-stick to metals and glass in molten form

- Low density of 2.2 g/cm3

- Low Mohs hardness (<2)

Boron Nitride Modified Platelet Powder Applications

- Thermal management material

- Lubricants

- Mold release agents in casting

- Anti-stick coatings

- High-temperature coatings

- Electronic packaging materials

- Surface modification materials

Boron Nitride Modified Platelet Powder Packaging

The Boron Nitride Modified Platelet Powder is carefully placed in wooden cases or cartons with additional support from soft materials to prevent any shifting during transportation. This packaging method guarantees the integrity of the products throughout the delivery process.

Download

Get A Quote

We will check and get back to you in 24 hours.